A kind of production method of potassium nitrate

A production method and technology of potassium nitrate, applied in the direction of alkali metal nitrate preparation, alkali metal nitrate purification, magnesium halide, etc., can solve the problems of high investment cost, large energy consumption, complex equipment structure, etc., and achieve low cost and high energy efficiency. The effect of low consumption and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

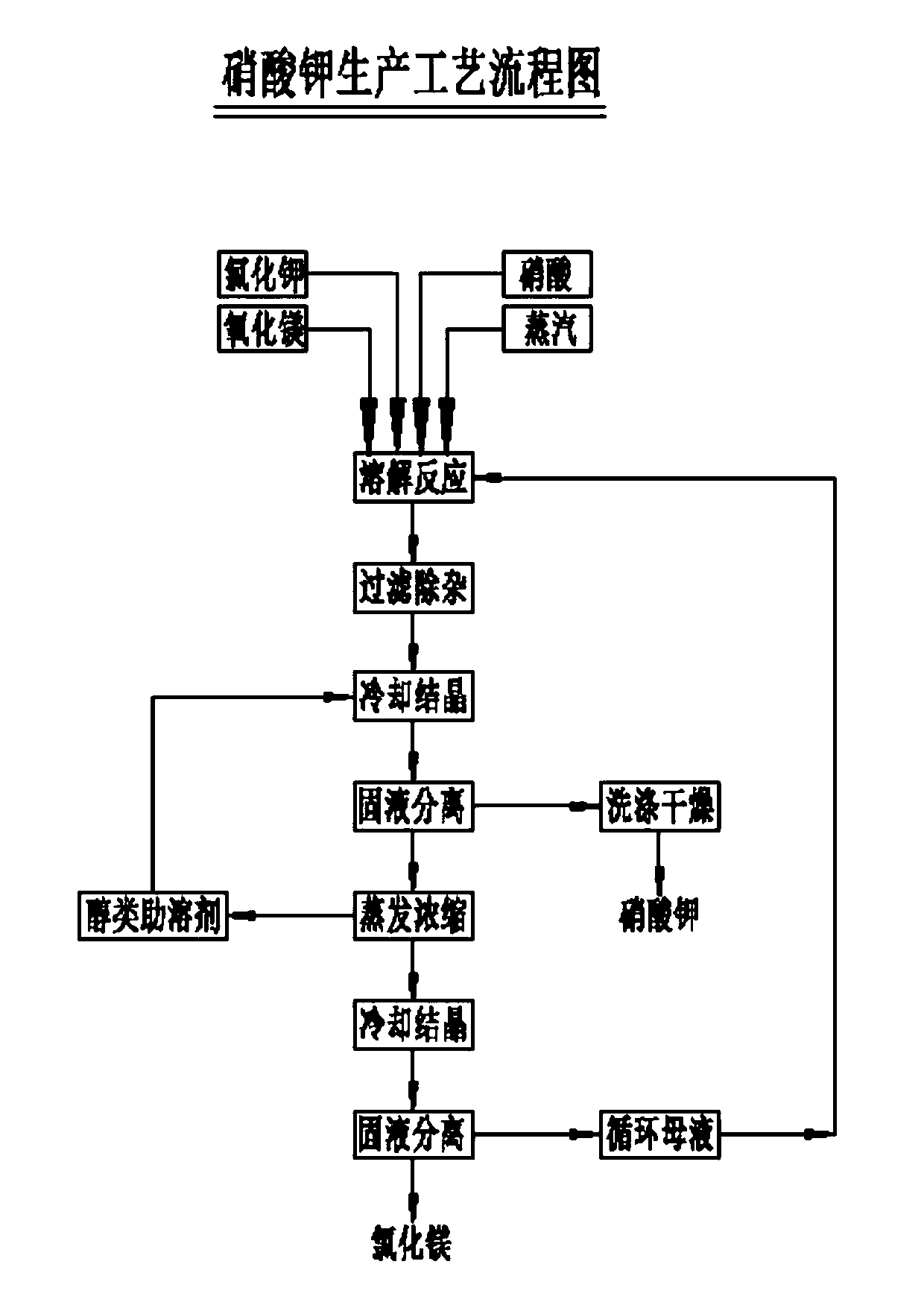

Image

Examples

Embodiment 1

[0051] Add 1,260 grams of 50% nitric acid into a 2000 ml four-necked flask equipped with a stirrer, condenser and thermometer, slowly add 195 grams of magnesium oxide powder under stirring, control the PH value between 2 and 7, and complete the oxidation. Magnesium continues to stir for 30 minutes, then slowly add 745 grams of solid potassium chloride, and then heat it with steam to dissolve it. Control the temperature at 60℃~110℃ to dissolve the solid potassium chloride, and then keep it at 100℃~110℃ for 1 hour. Distill part of the water; then filter while hot to remove the incompatible impurities in the material liquid; then transfer the filtrate to a 5000 ml flask with stirring, thermometer and cooling bath to cool and crystallize. When the temperature of the material liquid drops to 30°C, add Add 400 grams of methanol to the solution, continue to stir and crystallize, stir and crystallize at 20°C for 1 hour to make the potassium nitrate precipitate completely; then the solid...

Embodiment 2

[0053] Add 1,260 grams of 50% nitric acid into a 2000 ml four-necked flask equipped with a stirrer, condenser and thermometer, slowly add 195 grams of magnesium oxide powder under stirring, control the PH value between 2 and 7, and complete the oxidation. Magnesium continues to stir for 30 minutes, then slowly add 745 grams of solid potassium chloride, and then heat it with steam to dissolve it. Control the temperature at 60℃~110℃ to dissolve the solid potassium chloride, and then keep it at 100℃~110℃ for 1 hour. Distill part of the water; then filter while hot to remove the incompatible impurities in the material liquid; then transfer the filtrate to a 5000 ml flask with stirring, thermometer and cooling bath to cool and crystallize. When the temperature of the material liquid drops to 30°C, add Add 600 grams of methanol to the solution, continue to stir and crystallize. When the temperature drops to -10℃, stir and crystallize for 1 hour to make the potassium nitrate precipitat...

Embodiment 3

[0055] Add 1,260 grams of 50% nitric acid into a 2000 ml four-necked flask with stirring, condenser and thermometer, slowly add 195 grams of magnesium oxide powder under stirring, control the PH value between 2-7, and complete the oxidation. Magnesium continues to stir for 30 minutes, then slowly add 745 grams of solid potassium chloride, then heat it with steam to dissolve it, control the temperature at 60℃-110℃ to dissolve the solid potassium chloride, and then keep it at 100℃-110℃ for 1 hour. Distill part of the water; then filter while it is hot to remove the incompatible impurities in the material liquid; then transfer the filtrate to a 5000 ml flask equipped with stirring, thermometer and cooling bath to cool and crystallize. When the temperature of the material liquid drops to 20℃, Add 1000 grams of methanol to the solution, continue to stir and crystallize. When the temperature drops to -10°C, stir and crystallize for 1 hour to make the potassium nitrate precipitate comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com