High-strength stainless steel powder based on slm process and preparation method thereof

A high-strength, stainless steel technology, used in metal processing equipment, additive processing, transportation and packaging, etc., can solve problems such as bottlenecks in material selection, achieve good sphericity, improve fine powder yield, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

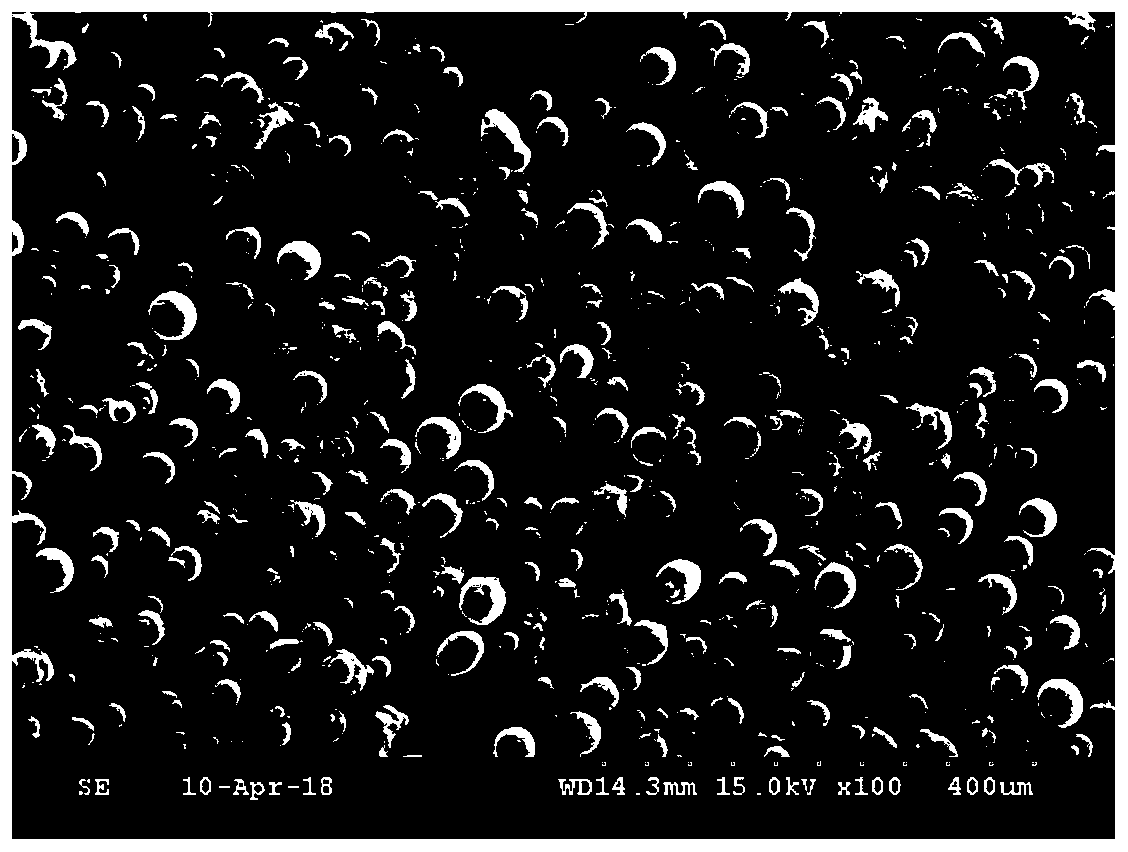

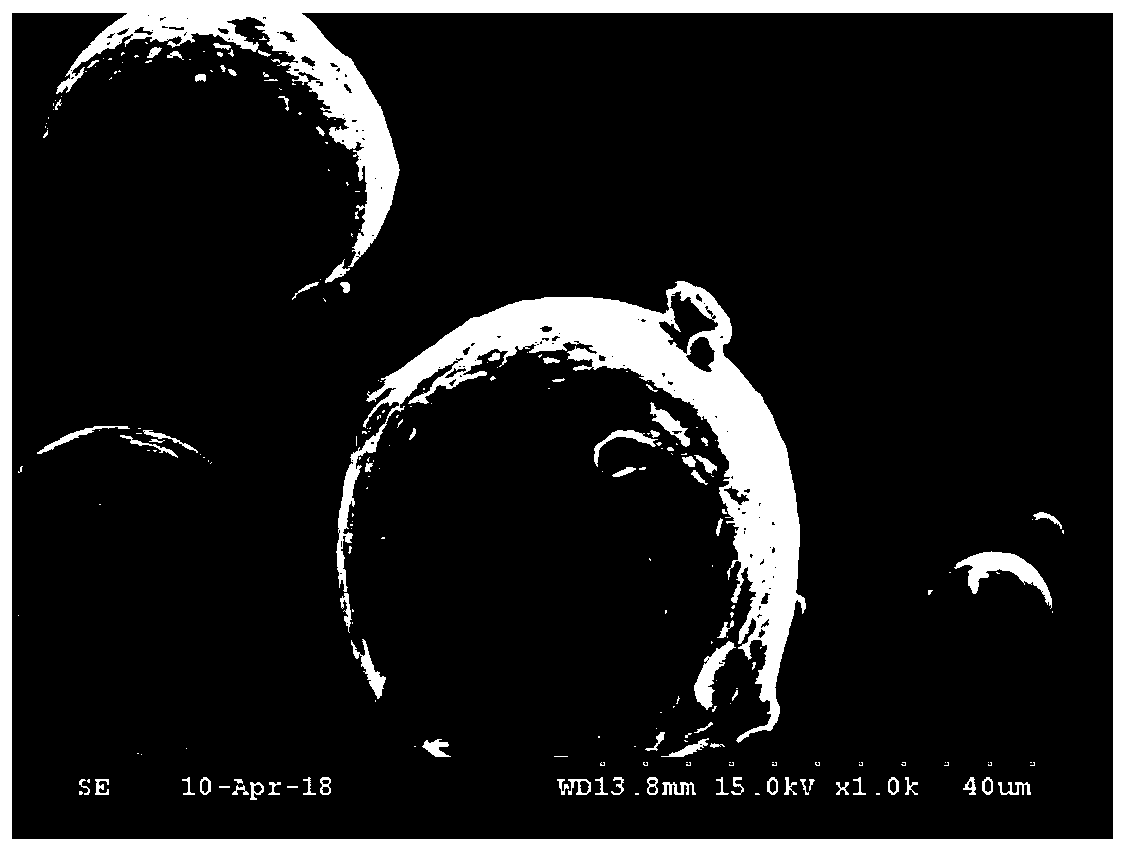

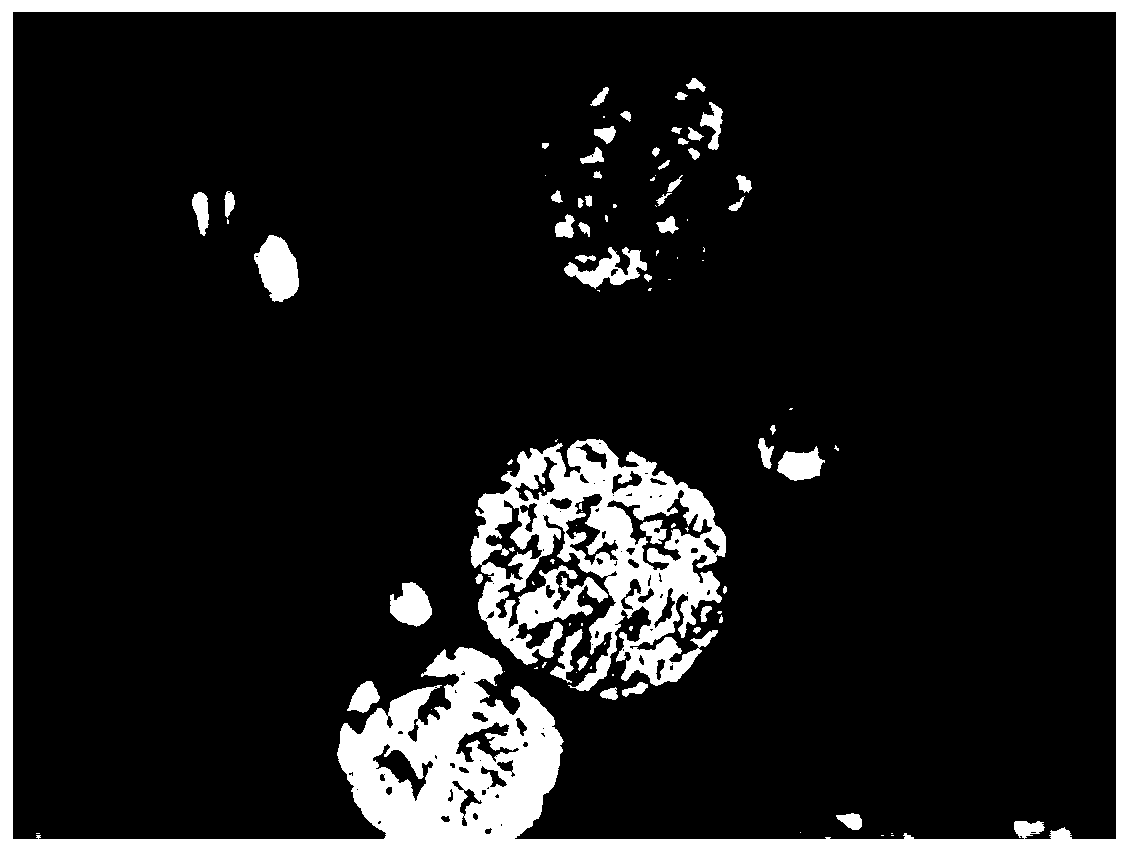

[0025] The embodiment of the present invention is three kinds of high-strength stainless steel metal powders with different yttrium content, and its chemical composition is shown in Table 1. Its preparation method is as follows: (1) Master alloy preparation: the embodiment all adopts vacuum induction furnace+vacuum consumable furnace double-joint smelting process to prepare master alloy, and its master alloy chemical composition is C: 0.028%, Si: 0.066%, Mn: 0.006%, P: 0.0045%, S: 0.0008%, Cr: 12.52%, Ni: 8.54%, Mo: 2.30%, Al: 1.14%, O: 0.0022%, and the balance is Fe and unavoidable impurities. (2) VIGA powder making: Put the master alloy into the VIGA melting crucible and vacuumize it. When the pressure drops below 0.1Pa, fill it with high-purity argon gas above 99.999% until the pressure is restored (repeat three times). Conduct induction heating, heating temperature to 1600-1680°C, after the master alloy is completely melted, add metal yttrium with different content, keep w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com