Preparation method of beef steak and the beef steak

A steak and fresh beef technology, applied in the function of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems affecting the taste of beef, achieve the effect of maintaining color and freshness, and removing sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

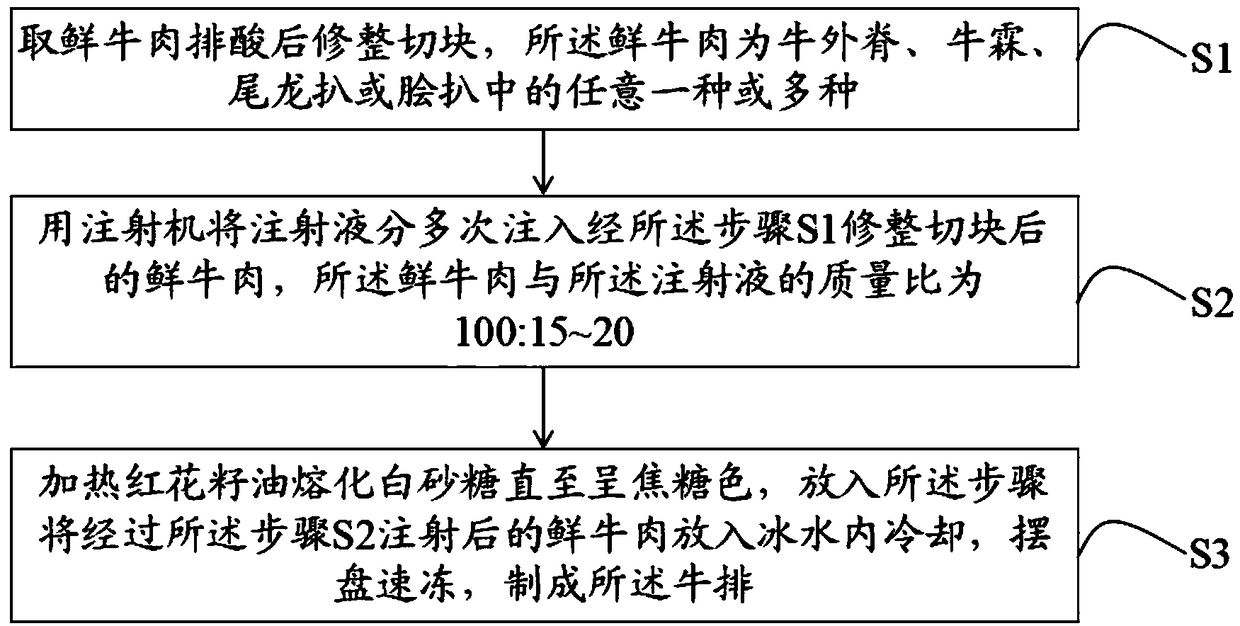

[0026] see figure 1 , is a schematic flow chart of an embodiment of the method for preparing steak of the present invention. The present invention proposes a kind of preparation method of steak, comprises the following steps:

[0027] Step S1, trimming and cutting fresh beef after deacidification, and the fresh beef is any one or more of beef loin, beef ribs, tailed dragon steak or fried steak;

[0028] Specifically, take any one or more kinds of fresh beef from the beef loin, Niu Lin, Weilong steak or fried steak, put it in a temperature of 0-4°C, hang it to cool and drain the acid for 24-48 hours, trim and cut it into pieces. After the cattle are slaughtered, the somatic cells lose the oxygen supply from the blood and undergo anaerobic respiration, which produces lactic acid that will affect the flavor of the beef. Put it in the temperature of 0-4℃ and hang it for 24-48 hours to cool and drain the acid. The lactic acid will be decomposed into carbon dioxide, water and alco...

Embodiment 1

[0039] Step S1, take 1 kg of beef loin, put it in a temperature of 2°C, hang it for cooling and deacidification for 36 hours, and shape it into a block;

[0040] Step S2, using an injection machine to inject 180g of injection into the fresh beef trimmed and diced in step S1 several times, the injection is 450g of safflower oil, 20g of papain, 15g of phosphate compound salt, 50g of soybean The protein isolate, 80g of clove extract, 80g of nutmeg extract by mass and 250g of water are put into a homogenizer and homogenized for 15 minutes.

[0041] The clove extract is to take 120g of clove powder and put it into 1L ethanol content of 52% liquor and soak it for more than 24h; the said nutmeg extract solution is to take 125g of nutmeg powder and put it into 1L ethanol content of 52% liquor and soak it for 24h Above, wherein, described liquor is Luzhou-flavor liquor.

[0042] In step S3, the fresh beef injected in step S2 is cooled in ice water with a water temperature of 13° C., p...

Embodiment 2

[0044] Step S1, take 1 kg of tailed dragon steak and put it in the temperature of 0°C, hang it for cooling and deacidification for 24 hours, and shape it into a block;

[0045]Step S2, use an injection machine to inject 150g of injection into the fresh beef trimmed and diced in step S1 several times. The injection is 400g of safflower oil, 10g of papain, 10g of phosphate compound salt, and 30g of soybean Protein isolate, 50g of clove extract, 50g of nutmeg extract by mass and 200g of water are put into a homogenizer and homogenized for 10 minutes.

[0046] The clove extract is to take 100g of clove powder and put it into 1L ethanol content of 53% liquor and soak it for more than 24h; the said nutmeg extract solution is to take 100g of nutmeg powder and put it into 1L ethanol content of 53% liquor and soak it for 24h Above, wherein, described liquor is Luzhou-flavor liquor.

[0047] In step S3, the fresh beef injected in step S2 is cooled in ice water at a water temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com