Centralized straw recovery processing device

A technology of recycling and concentration, applied in waste treatment, solid fuel, application, etc., can solve the problems of less recycling and utilization of withered crop straw resources, no device recycling, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

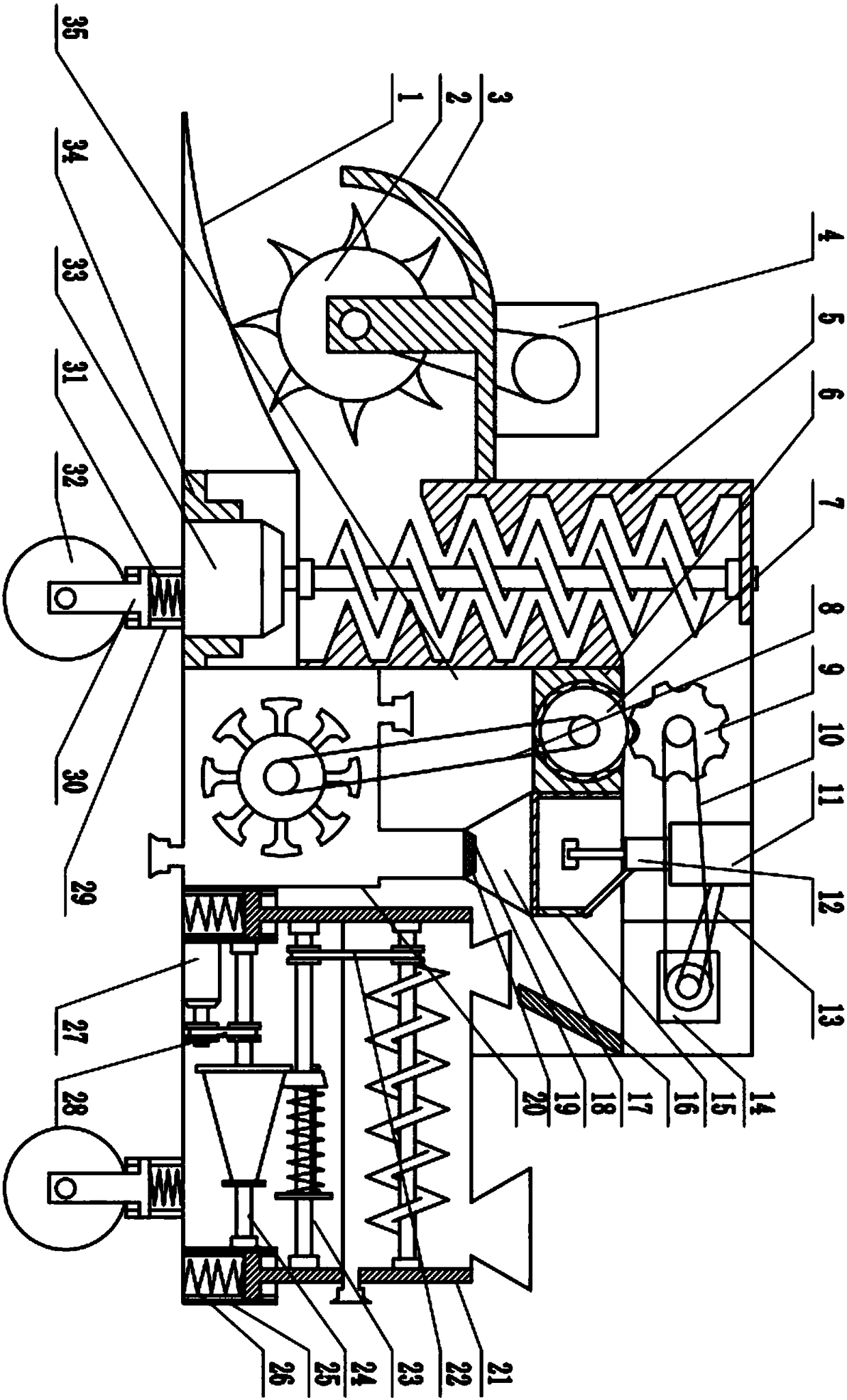

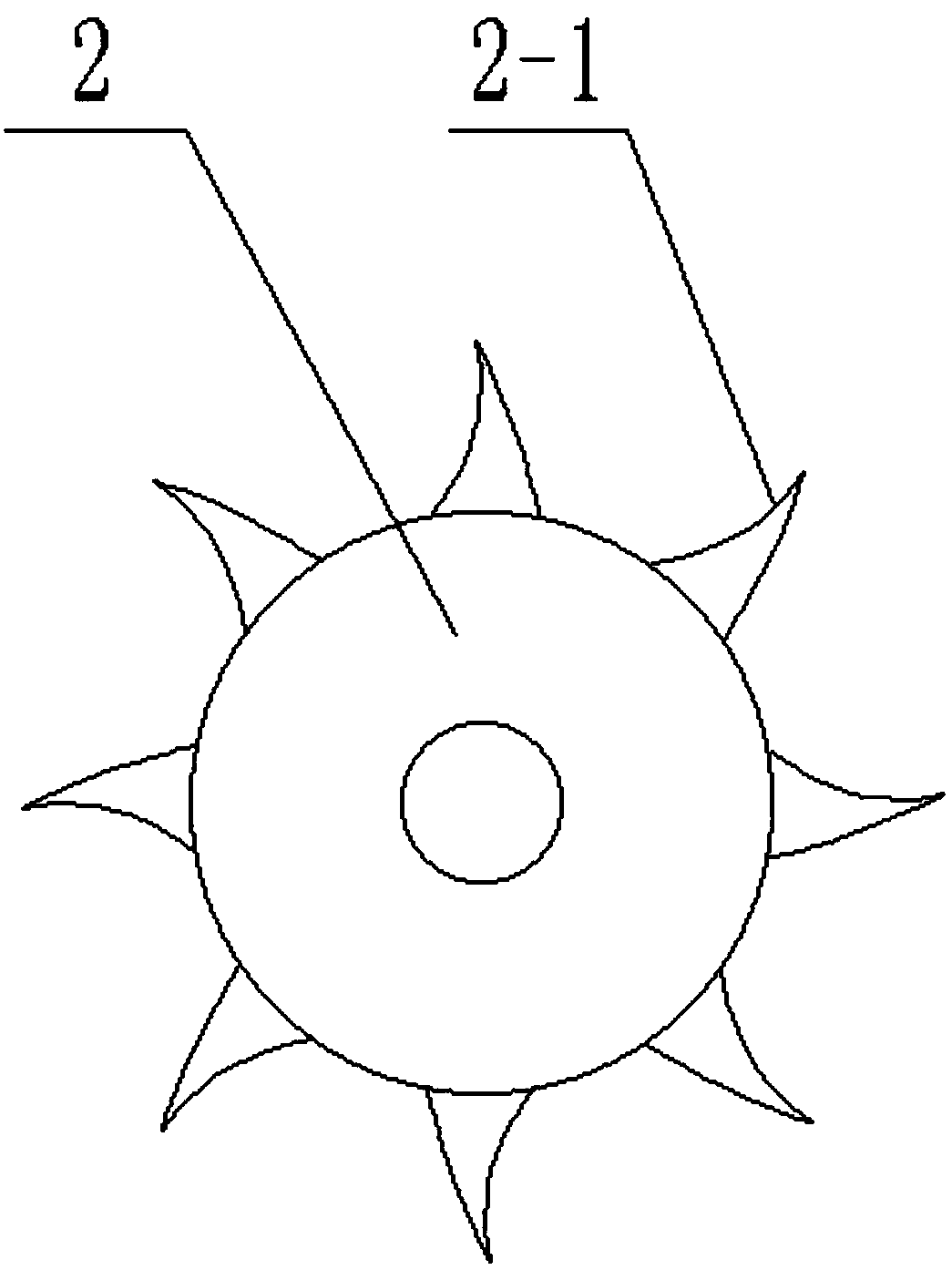

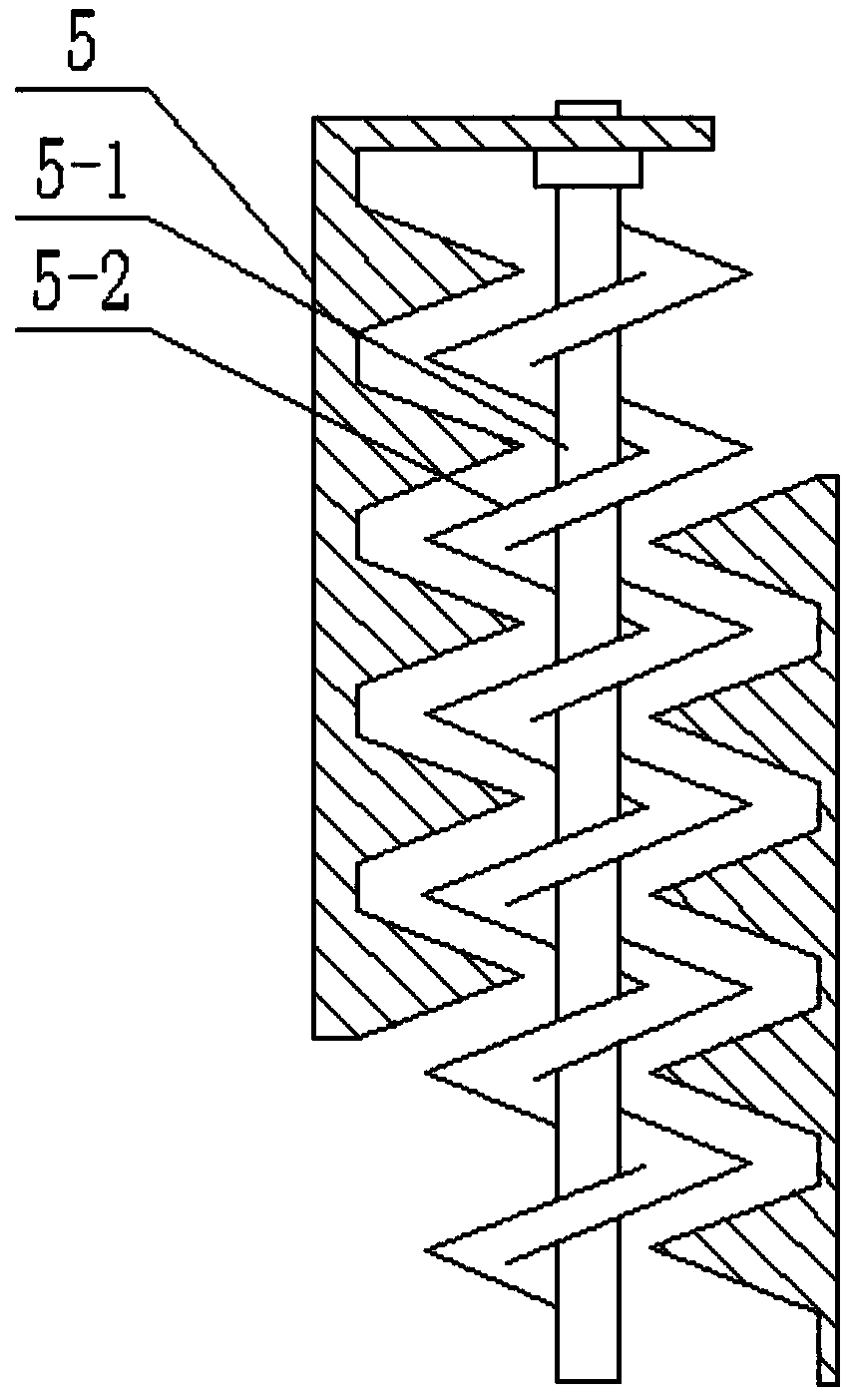

[0034] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 illustrate this embodiment. The main technical problem to be solved by the present invention is to provide a centralized straw recovery treatment device, which includes a shovel 1, a pushing roller 2, a pushing roller Baffle plate 3, motor Ⅰ4, crushing screw shell 5, convex crushing roller base 6, convex crushing roller 7, crushing roller belt 8, concave crushing roller 9, concave crushing stick belt 10 , gear box 11, extruder shell 12, motor Ⅱ belt 13, motor Ⅱ 14, anti-overflow hinged plate 15, broken material limit plate 16, filter 17, filter net box 18, filter screen 19, fermentation mixing box 20, Dry material agitator 21, dry material agitator belt 22, small helical gear shaft 23, large helical gear shaft 24, dry material agitator sleeve 25, dry material agitator sleeve spring 26, motor III 27, motor III belt 28, Wheel sleeve 29, wheel support arm 30, wheel sleeve spring 31, wheel 32, crushing screw motor 3...

specific Embodiment approach 2

[0044] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The extruder articulated arm 12-3, sliding support arm 12-6, There are two extrusion plates 12-7, dry material agitator 21, dry material agitator sleeve 25, and dry material agitator sleeve spring 26.

specific Embodiment approach 3

[0045] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The described small helical gear shaft 23, small helical gear shaft pulley 23-1, small The helical gear 23-2 and the small helical gear limit retaining ring 23-5 share the central line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com