Durable diatom ooze decoration wall material powder and preparation method thereof

A diatom mud and durability technology, applied in the field of decorative materials, can solve the problems of affecting the durability and service life of diatom mud coatings, blocking diatom mud pores, and low strength of diatom mud, so as to improve durability and solve The effect of pore clogging, not easy to drop powder and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

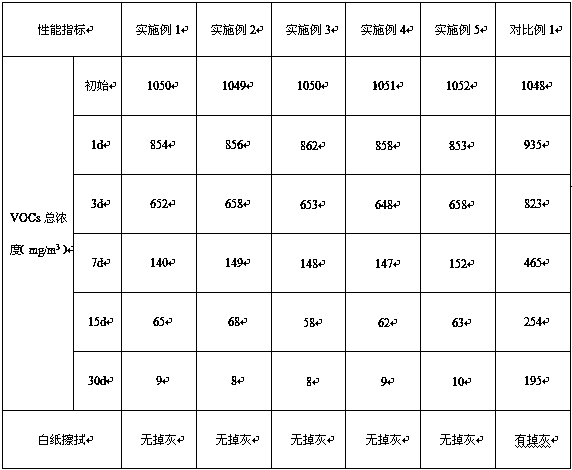

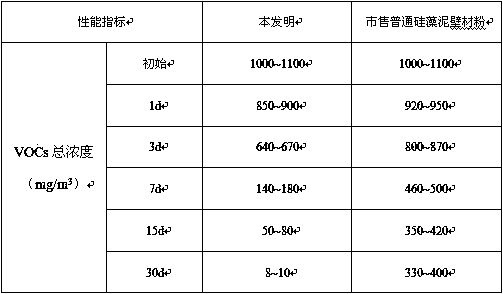

Examples

Embodiment 1

[0032] (1) First sieve the diatomite, take 35 mesh diatomite, and then add the powdered foaming agent into the powder modification machine, stir and mix, so that the foaming agent is evenly dispersed in the diatomite In the hole; wherein: 89 parts by weight of diatomite, 11 parts by weight of foaming agent; powdery foaming agent is potassium bicarbonate powder;

[0033] (2) Spray and deposit graphene-containing water-soluble emulsion on the surface of diatomite loaded with foaming agent to form a layer of diaphragm, and dry to obtain surface-modified diatomite; wherein: the thickness of the graphene-containing diaphragm is 0.1 μm The water-soluble emulsion is a water-soluble polyurethane emulsion; in the water-soluble emulsion, the mass fraction of graphene is 5%;

[0034] (3) Add the surface-modified diatomite prepared in step (2), binder, dispersant, inorganic pigment, inorganic filler, and fiber toughening agent into a high-speed mixer, and stir and mix at a speed of 112r / m...

Embodiment 2

[0037] (1) First sieve the diatomite, take 25 mesh diatomite, and then add the powdered foaming agent into the powder modification machine, stir and mix, so that the foaming agent is evenly dispersed in the microscopic diatomite In the hole; wherein: 85 parts by weight of diatomite, 15 parts by weight of foaming agent; the powdery foaming agent is sodium bicarbonate powder;

[0038] (2) Spray and deposit graphene-containing water-soluble emulsion on the surface of diatomite loaded with foaming agent to form a layer of diaphragm, and dry to obtain surface-modified diatomite; wherein: the thickness of the graphene-containing diaphragm is 0.05 μm The water-soluble emulsion is a water-soluble acrylic emulsion; in the water-soluble emulsion, the mass fraction of graphene is 3%;

[0039](3) Add the surface-modified diatomite prepared in step (2), binder, dispersant, inorganic pigment, inorganic filler, and fiber toughening agent into a high-speed mixer, and stir and mix at a speed o...

Embodiment 3

[0042] (1) First sieve the diatomite, take 50 mesh diatomite, and then add it to the powder modification machine together with the powdered foaming agent, stir and mix, so that the foaming agent is evenly dispersed in the fine grains of diatomite In the hole; wherein: 92 parts by weight of diatomite, 8 parts by weight of foaming agent; the powdery foaming agent is ammonium bicarbonate powder;

[0043] (2) Spray and deposit a graphene-containing water-soluble emulsion on the surface of diatomite loaded with foaming agent to form a layer of diaphragm, and dry to obtain surface-modified diatomite; wherein: the thickness of the graphene-containing diaphragm is 0.2 μm The water-soluble emulsion is a water-soluble acrylic resin emulsion; in the water-soluble emulsion, the mass fraction of graphene is 6%;

[0044] (3) Add the surface-modified diatomite prepared in step (2), binder, dispersant, inorganic pigment, inorganic filler, and fiber toughening agent into a high-speed mixer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap