High-strength abrasion-resistant PA 66 (polyamide 66) composite material and method for preparing same

A technology of PA66 and composite materials, which is applied in the field of high-strength and wear-resistant PA66 composite materials and its preparation, can solve the problems of not having high strength, etc., and achieve the effects of simple production process and equipment, low friction coefficient and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

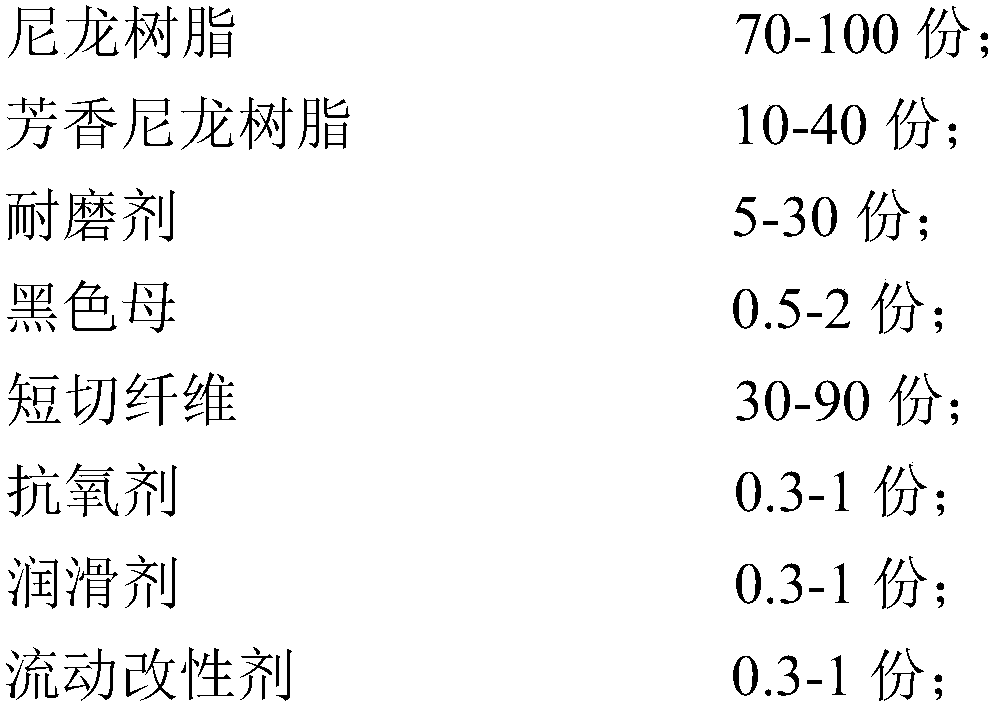

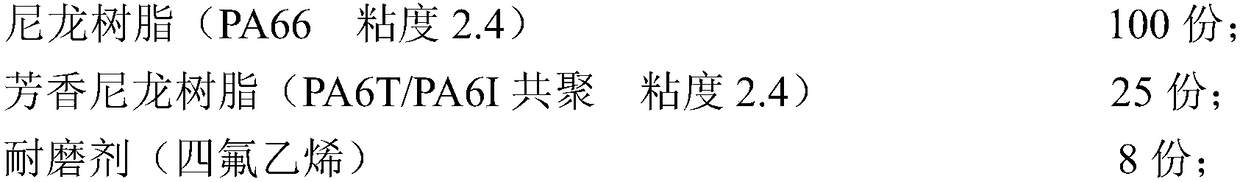

[0030] A high-strength wear-resistant PA66 composite material, first weigh the following materials in parts by weight:

[0031]

[0032]

[0033] Chopped fiber is hydrolysis-resistant alkali-free chopped glass fiber treated with silane coupling agent, the fiber length is 1-4mm; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] pentaerythritol ester, tris (2,4-di-tert-butylphenyl) phosphite compound, the ratio is 1:2 by weight; the lubricant is silicone powder, pentaerythritol stearic acid The compound of two kinds of esters has a ratio of 1:1 by weight; the flow modifier is a hyperbranched high-molecular-weight polyhydroxy complex alcohol ester with polar groups.

[0034] The above materials are put into the mixer and mixed evenly, and then the mixed materials are put into the main lower barrel of the extruder and granulated by the extruder. During the extrusion process, 85 parts of chopped fibers are passed through the side feeding The t...

Embodiment 2

[0036] The present embodiment differs from Example 1 in that: first take the following materials in parts by weight:

[0037]

[0038] Chopped fiber is hydrolysis-resistant alkali-free chopped glass fiber treated with silane coupling agent, and the fiber length is 1-4mm; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionic acid] pentaerythritol ester, phosphite tris (2,4-di-tert-butylphenyl) compound, the ratio is 1:3 by weight; the lubricant is silicone powder, pentaerythritol stearin A compound of two esters, the ratio of which is 1:3 by weight; the flow modifier is a hyperbranched high-molecular-weight polyhydroxy complex alcohol ester with polar groups.

[0039] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main feeding barrel of the extruder and granulate through the extruder. During the extrusion process, 60 parts of chopped fibers pass through the side feeding The temperature of each tempera...

Embodiment 3

[0041] The present embodiment differs from Example 1 in that: first take the following materials in parts by weight:

[0042]

[0043] Chopped fiber is hydrolysis-resistant alkali-free chopped glass fiber treated with silane coupling agent, the fiber length is 3-4mm; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] pentaerythritol ester, tris (2,4-di-tert-butylphenyl) phosphite compound, the ratio is 1:2 by weight; the lubricant is silicone powder, pentaerythritol stearic acid The compound of two kinds of esters has a ratio of 1:1 by weight; the flow modifier is a hyperbranched high-molecular-weight polyhydroxy complex alcohol ester with polar groups.

[0044]Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 60 parts of chopped fibers pass through the side feeding Add by way, keep the vacuum ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com