Processing method of food packaging paper

A technology of food wrapping paper and processing method, which is applied in textiles and papermaking, papermaking, rosin addition and other directions, can solve the problems of slow production speed and complicated packaging paper production steps, and achieves the effects of rapid beating, improved mixing efficiency and fast processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

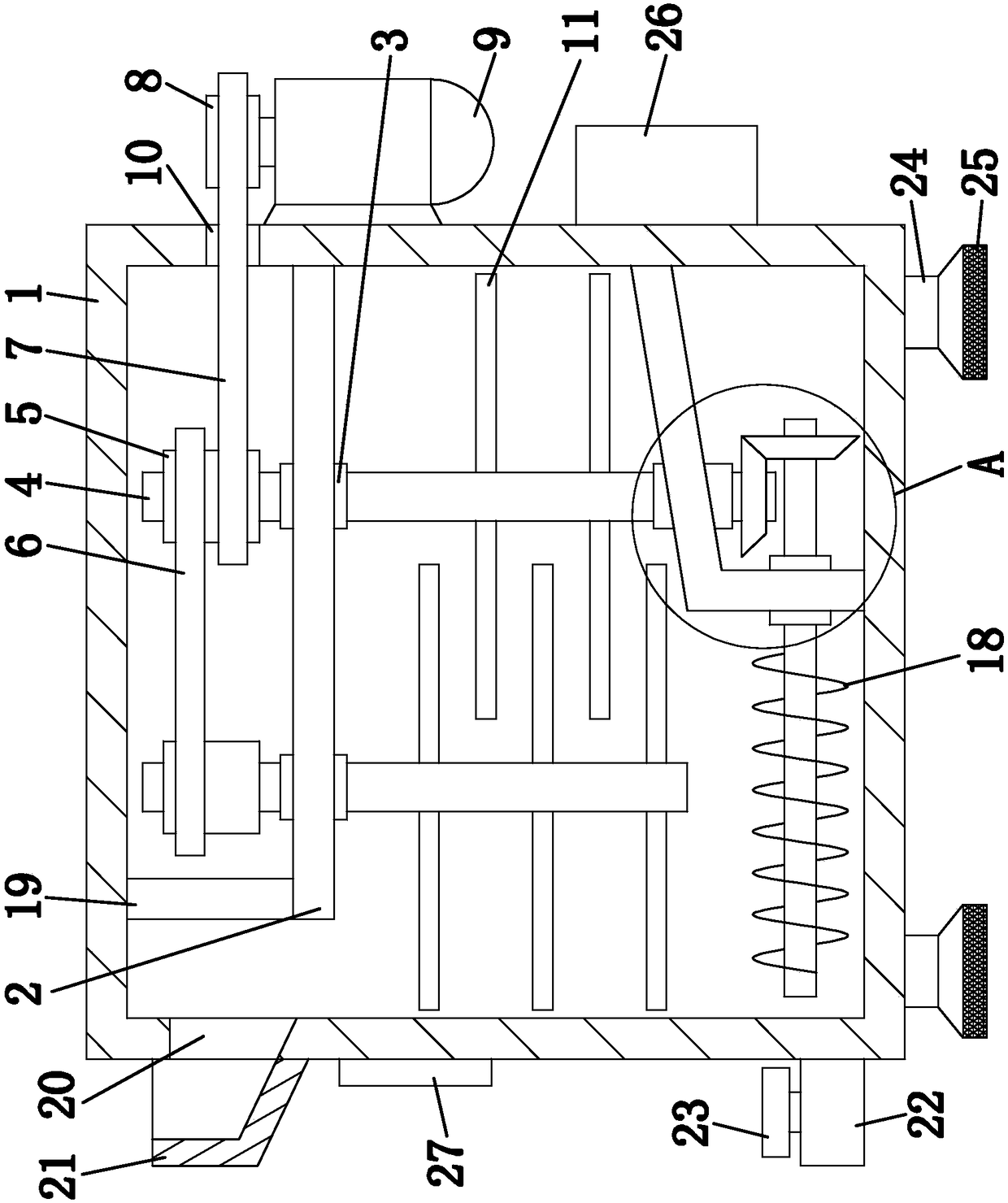

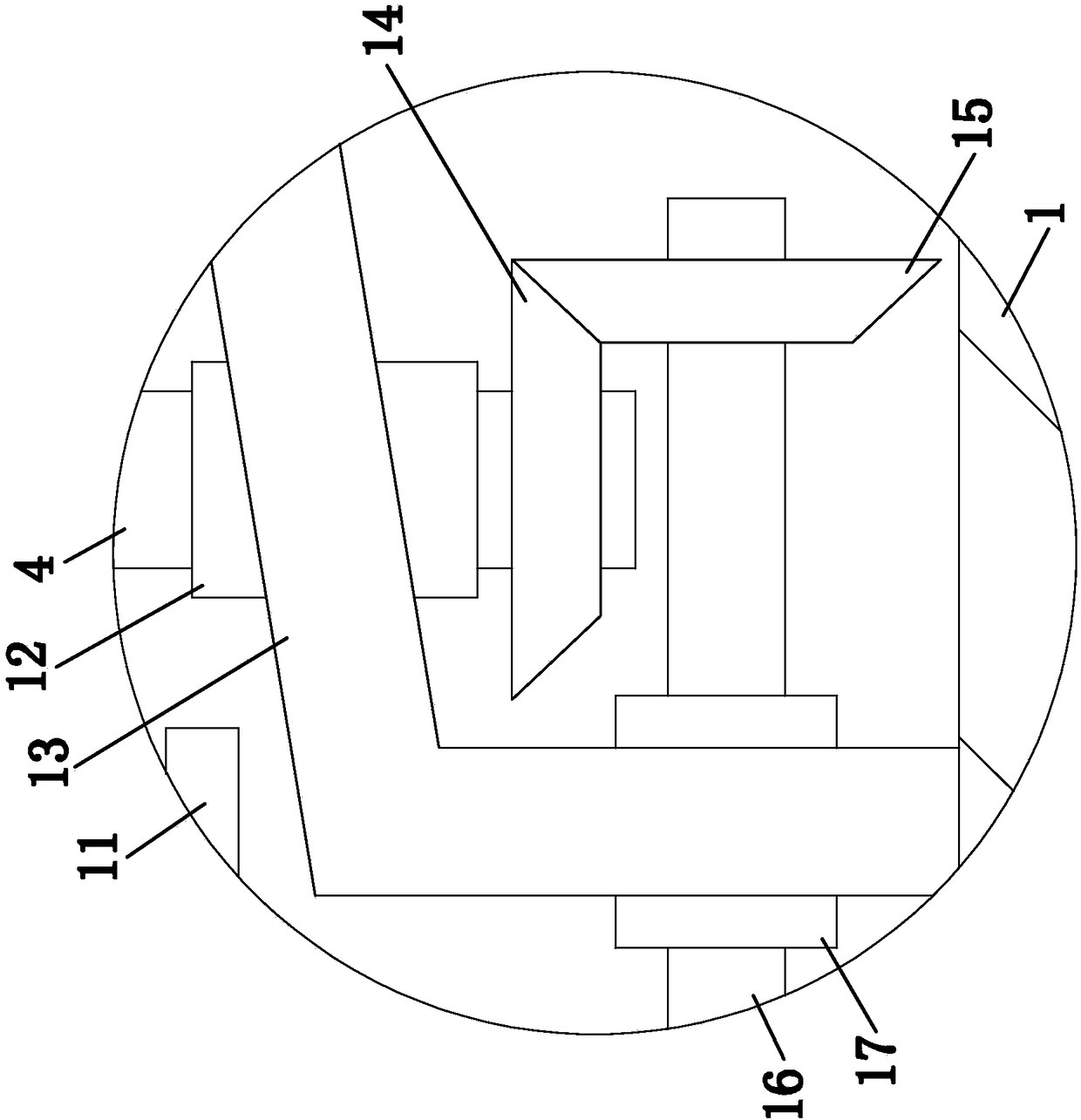

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0030] The processing method of this food packaging paper comprises the steps:

[0031] a. In parts by weight, weigh 30-40 parts of bitter bark vine, 2.5-4.5 parts of calcium carbonate, 10-20 parts of Chinese fir powder, 22-26 parts of water chestnut powder, 5-10 parts of straw powder, and 3.2-3 parts of dispersed rosin gum. 4.8 parts and 80-120 parts of water; in the present embodiment, weigh 32 parts of bitter bark vine, 2.8 parts of calcium carbonate, 12 parts of fir powder, 23 parts of water chestnut powder, 7 parts of straw powder, 3.9 parts of dispersed rosin gum and water 100 copies;

[0032] B, get the stem bark and water of bitter vine and put it into the beating device together for beating, the stirring time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com