Water-system complex-formulation electrolyte and preparation method and application thereof

An electrolyte and water system technology, applied in the field of water system composite electrolyte and its preparation, can solve the problems of low energy density of supercapacitors, and achieve the effects of simple and easy preparation process, improved reactivity and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

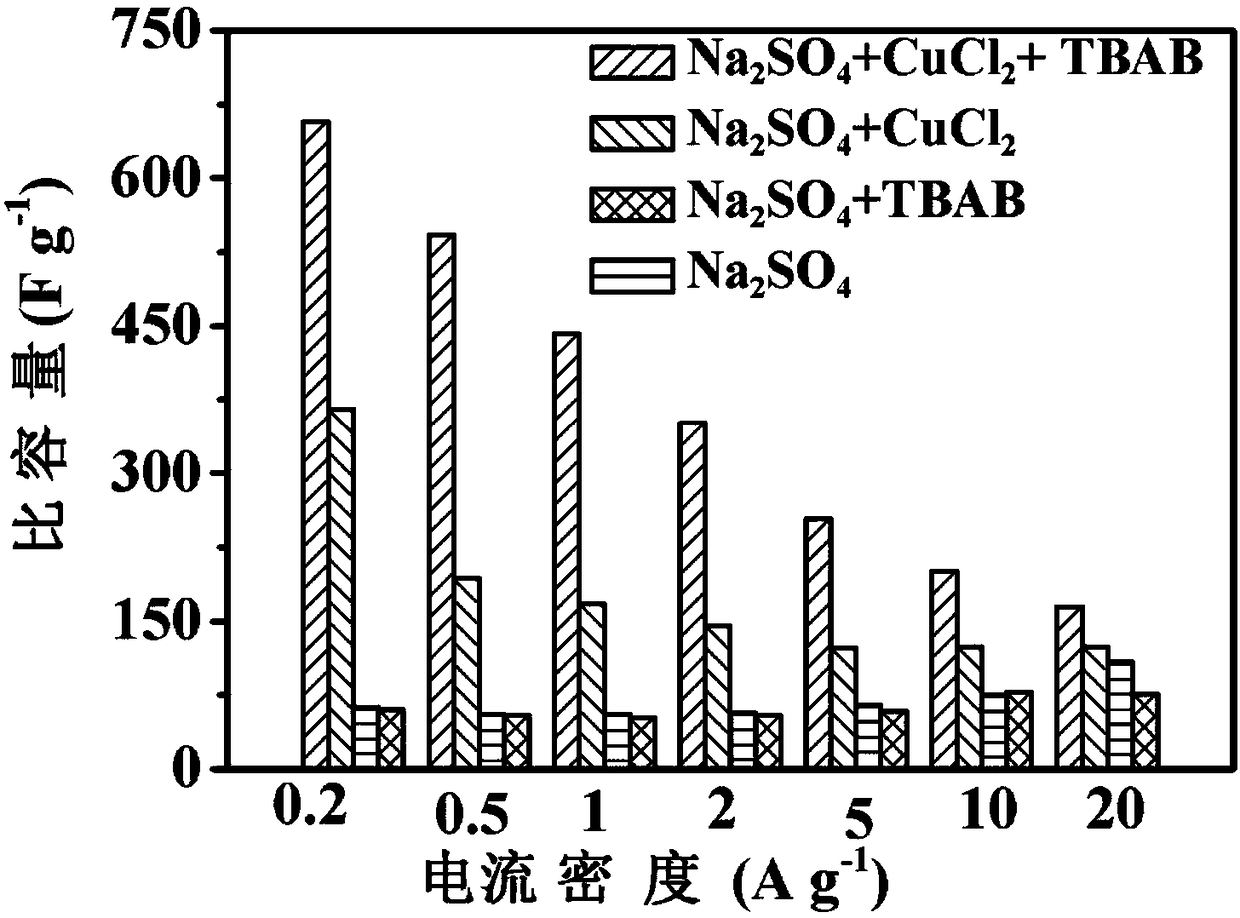

[0023] Sodium sulfate was added to deionized water to prepare a neutral electrolyte solution with a concentration of 0.5 mol / L, placed on a magnetic stirrer at a speed of 400 r / min, and stirred for 1 h.

[0024] Add copper chloride dihydrate solution to the neutral electrolyte to prepare a metal salt solution with a concentration of 0.005mol / L, place it on a magnetic stirrer at a speed of 400r / min, and stir for 1h.

[0025] Continue to add tetrabutylammonium bromide to the prepared solution to form a composite electrolyte solution with a concentration of 0.005mol / L, place it on a magnetic stirrer at a speed of 400r / min, and stir for 1h. Then the electrochemical test was carried out with activated carbon as the electrode material.

Embodiment 2

[0027] Sodium sulfate was added to deionized water to prepare a neutral electrolyte solution with a concentration of 0.5 mol / L, placed on a magnetic stirrer at a speed of 400 r / min, and stirred for 1 h.

[0028] Add copper chloride dihydrate solution to the neutral electrolyte to prepare a metal salt solution with a concentration of 0.5mol / L, place it on a magnetic stirrer at a speed of 400r / min, and stir for 1h.

[0029] Continue to add tetrabutylammonium bromide to the prepared solution to form a composite electrolyte solution with a concentration of 0.025mol / L, place it on a magnetic stirrer at a speed of 400r / min, and stir for 1h. Then the electrochemical test was carried out with activated carbon as the electrode material.

Embodiment 3

[0031] Add sodium sulfate to deionized water to prepare a neutral electrolyte solution with a concentration of 0.5 mol / L, place it on a magnetic stirrer at a speed of 400 r / min, and stir for 2 hours.

[0032] Add copper chloride dihydrate solution to the neutral electrolyte to prepare a metal salt solution with a concentration of 0.5 mol / L, place it on a magnetic stirrer at a speed of 400 r / min, and stir for 2 hours.

[0033]Continue to add tetrabutylammonium bromide to the prepared solution to prepare a compound electrolyte solution with a concentration of 0.1mol / L, place it on a magnetic stirrer at a speed of 400r / min, and stir for 2h. Then the electrochemical test was carried out with activated carbon as the electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com