Drying agent used for storing unhusked rice

A desiccant and paddy technology, applied in the field of paddy storage, can solve the problems of reduced viscosity, reduced water absorption, heat and mildew of paddy, etc., and achieve the effects of reducing paddy mold and insects, good dehumidification effect, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

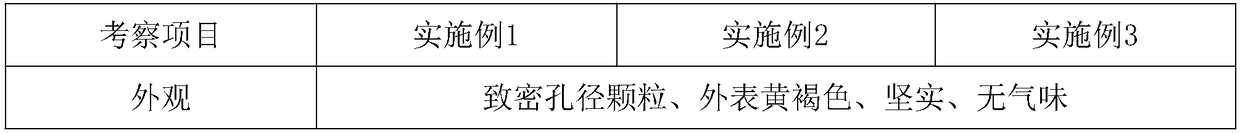

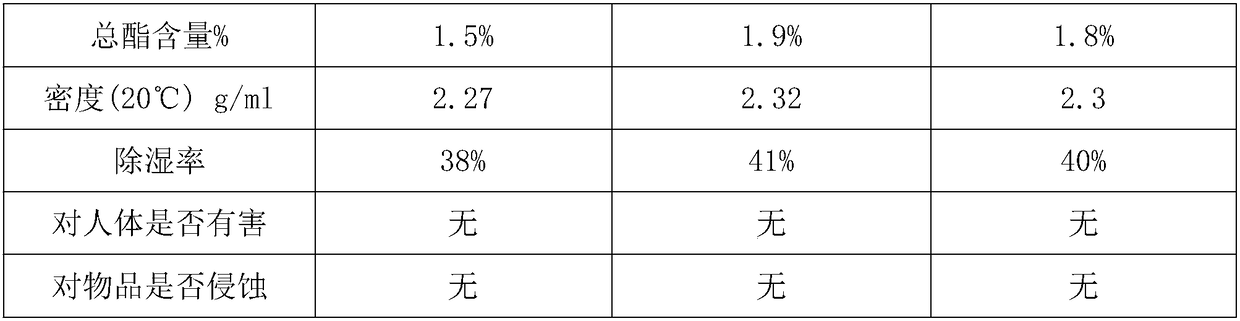

Examples

Embodiment 1

[0019] A desiccant for rice storage, made of the following raw material components in parts by weight:

[0020] 30 parts of calcium chloride, 15 parts of wheat straw, 5 parts of activated carbon, 15 parts of modified starch, 10 parts of montmorillonite, 10 parts of glycerin, 3 parts of silicon dioxide, 8 parts of ethanol, 5 parts of nano rubber powder, SiO 2 - 2 parts of alginate, 2 parts of polyvinylpyrrolidone-graphene oxide.

[0021] The modified starch is made of the following raw materials in parts by weight: 60 parts of cornstarch, 10 parts of acrylamide, 5 parts of citric acid, and 4 parts of nano-alumina. The preparation method is as follows: first disperse the cornstarch in water to prepare Make a starch slurry, then add citric acid, heat up to 50°C and keep stirring for 10 minutes, then add acrylamide and nano-alumina, mix well, then microwave at a microwave frequency of 2450MHz and 600W for 12 minutes, and finally grind it into powder after drying. Corn starch has ...

Embodiment 2

[0029] A desiccant for rice storage, made of the following raw material components in parts by weight:

[0030] 40 parts of calcium chloride, 20 parts of wheat straw, 10 parts of activated carbon, 20 parts of modified starch, 15 parts of montmorillonite, 15 parts of glycerin, 6 parts of silicon dioxide, 15 parts of ethanol, 10 parts of nano rubber powder, SiO2-seaweed 5 parts of salt, 5 parts of polyvinylpyrrolidone-graphene oxide.

[0031] The modified starch is made of the following raw materials in parts by weight: 80 parts of cornstarch, 20 parts of acrylamide, 10 parts of citric acid, and 6 parts of nano-alumina. The preparation method is as follows: first disperse the cornstarch in water to prepare Make a starch slurry, then add citric acid, heat up to 60°C and keep stirring for 15 minutes, then add acrylamide and nano-alumina, mix well, then microwave at a microwave frequency of 2450MHz and 600W for 15 minutes, and finally grind it into powder after drying. Corn starch...

Embodiment 3

[0039] A desiccant for rice storage, made of the following raw material components in parts by weight:

[0040] 35 parts of calcium chloride, 18 parts of wheat straw, 8 parts of activated carbon, 18 parts of modified starch, 12 parts of montmorillonite, 13 parts of glycerin, 5 parts of silicon dioxide, 12 parts of ethanol, 8 parts of nano rubber powder, SiO2-seaweed 4 parts of acid salt, 3 parts of polyvinylpyrrolidone-graphene oxide.

[0041] The modified starch is made of the following raw materials in parts by weight: 70 parts of cornstarch, 15 parts of acrylamide, 8 parts of citric acid, and 5 parts of nano-alumina. The preparation method is as follows: first disperse the cornstarch in water to prepare Make a starch slurry, then add citric acid, heat up to 55°C and keep stirring for 13 minutes, then add acrylamide and nano-alumina, mix well, then microwave at a microwave frequency of 2450MHz and 600W for 14 minutes, and finally dry it and grind it into powder. Corn starch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com