Environment-friendly microalgae cultivating method

A microalgae culture and environment-friendly technology, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., to achieve the effect of improving CO2 utilization and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Sludge dewatering solution

[0031] Municipal sewage was taken from the sludge dewatering liquid of a municipal sewage treatment plant in Wuxi City, Jiangsu Province (produced from the sludge dewatering process). After natural sedimentation, the water samples were filtered with filter paper (qualitative filter paper 11 cm) to remove larger particles in the sewage. Chlorella will be cultured in the sedimented and filtered sewage water samples, and the water quality indicators of the sludge dewatering solution are shown in Table 2.

[0032] Table 2 Water quality characteristics of sludge dewatering solution

[0033]

Embodiment 2

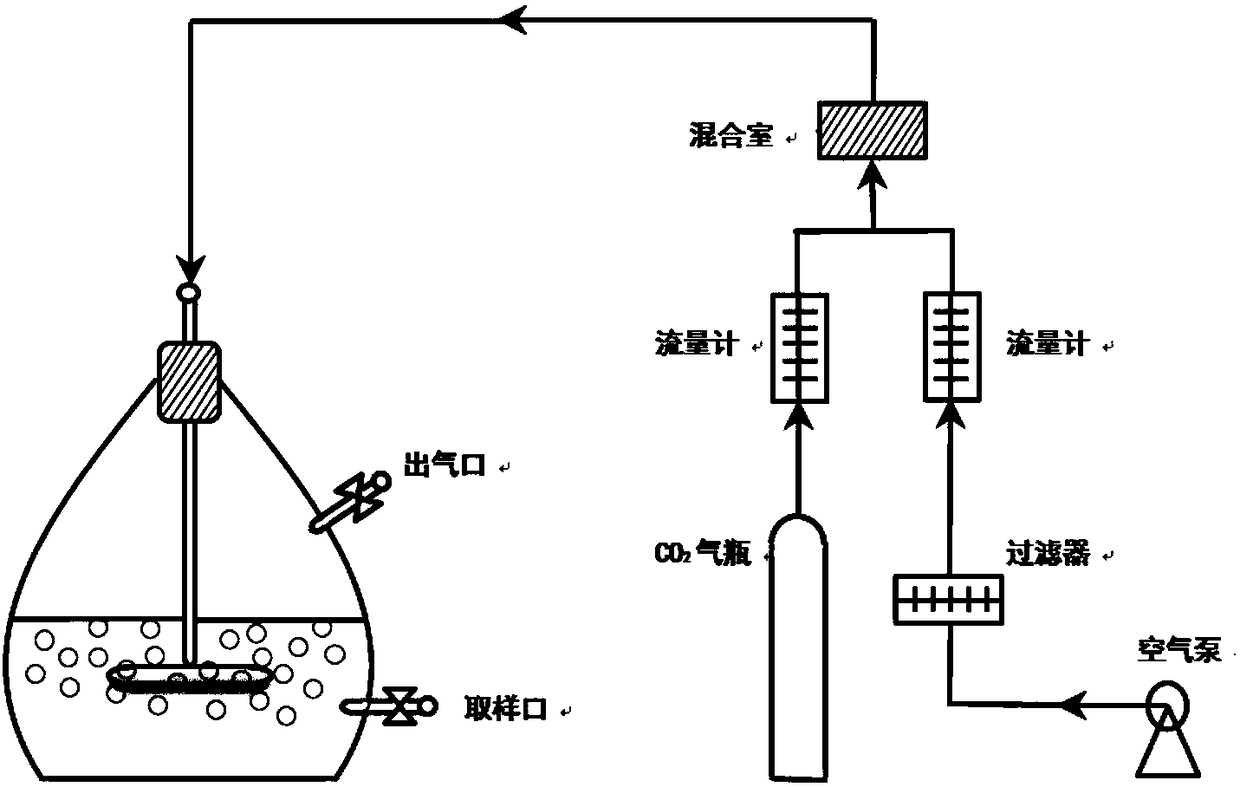

[0034] Example 2: Sludge dewatering solution coupled with CO 2 Photobioreactor for growing microalgae

[0035] like figure 1 As shown, this experiment uses a 3.5L photobioreactor (PBR) as the experimental device, the sewage culture volume is 2.5L, and the reactor is provided with a sampling port and an air inlet and outlet. The reactor was placed in a constant temperature light incubator, the culture conditions were 25 ± 1 °C, and the light intensity was 50 μmol m -2 s -1 , the light-dark ratio is 12 / 12h (day / night). Set up different CO 2 Concentrations (5%, 10%, 15%, and 20%) Experimental group, and air was used as the control group. Aeration was performed at the beginning of the photoperiod, with sterile air and different concentrations of CO, respectively 2 gas. The flow rate was 250 mL / min and the time was 30 min.

Embodiment 3

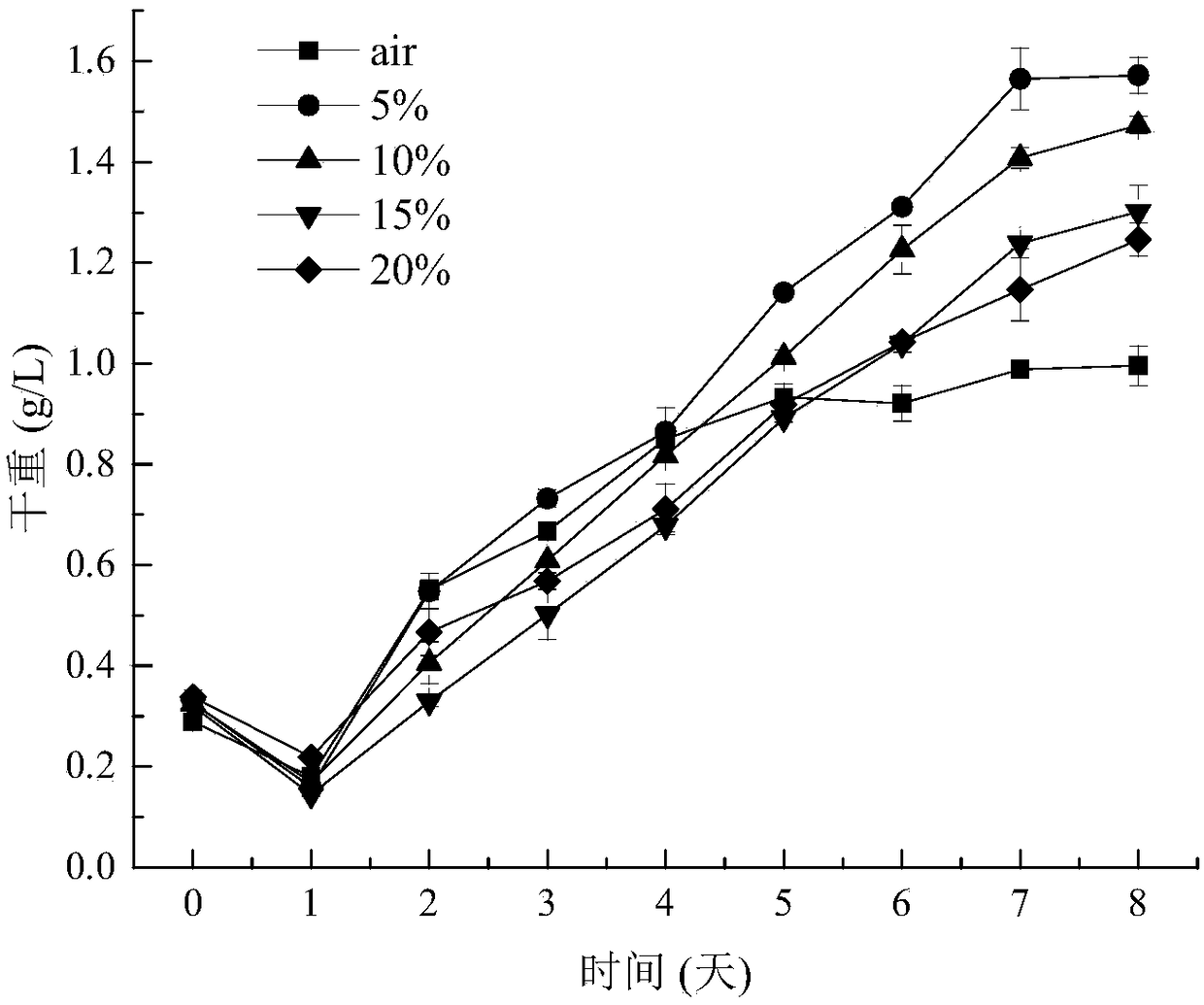

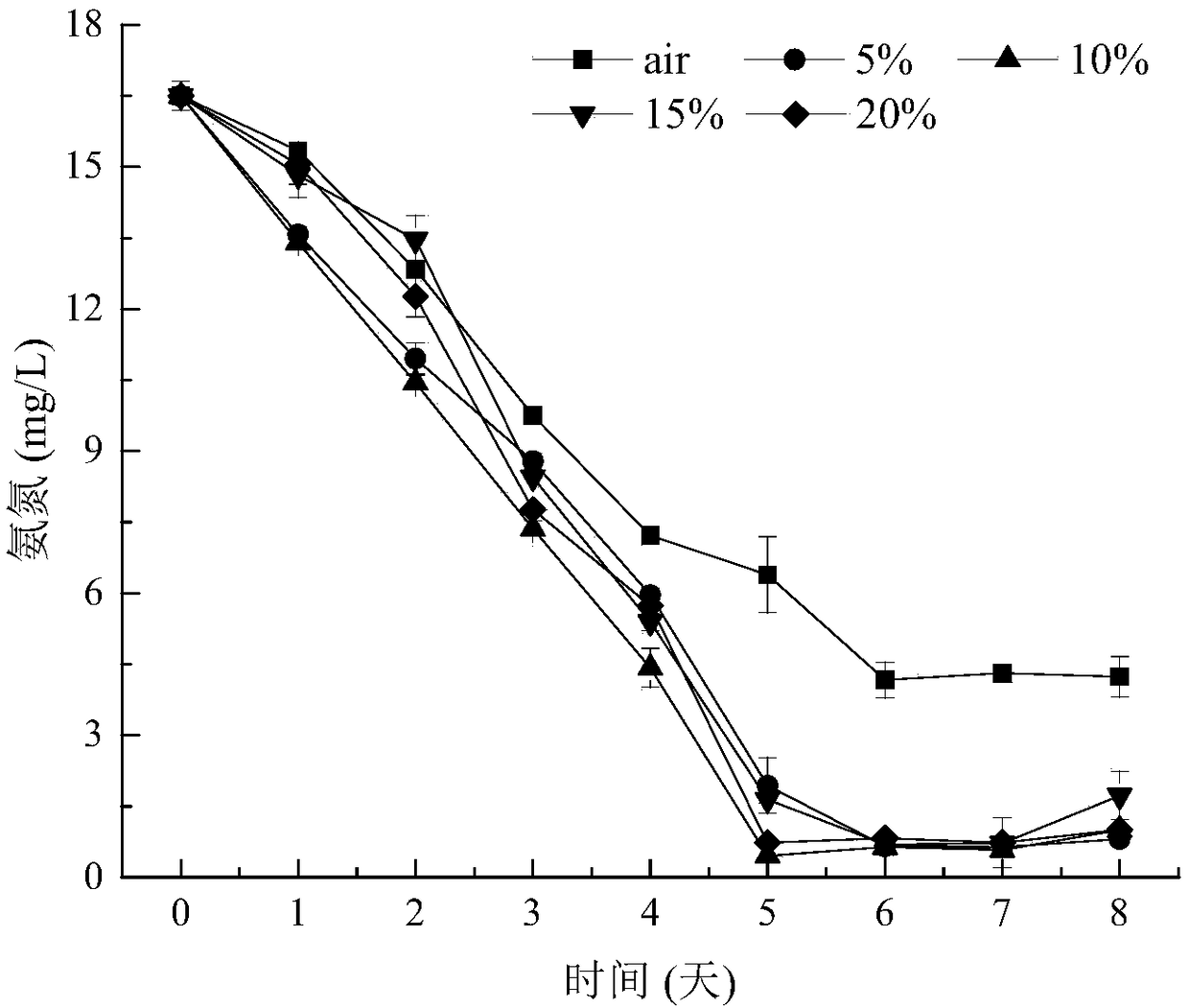

[0036] Example 3: Different CO in sludge dewatering solution 2 Growth of Chlorella at Concentrations

[0037] The algae liquid grown to the exponential stage was centrifuged at 3000r / min for 5 minutes, washed three times with deionized water, and resuspended. In order to ensure the same initial conditions of the experiment, the inoculation density of algae in each experimental group was about 0.3g / L. pH. Regular sampling to determine the density of algae in water samples (OD) 680 ).

[0038] like figure 2 shown, for Chlorella at different CO 2 The change curve of biomass under concentration. Results After 8 days of culture, CO 2 The biomass obtained in the group was higher than that in the control group. It indicated that the organic carbon in the sludge dewatering solution could not meet the requirement of carbon source during the rapid growth of Chlorella, and Chlorella was in a carbon-limited culture condition. The aeration function fully mixes the algae liquid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com