Multi-stage jet spray gravity backwater draught fan-free filler-free type cooling device

A cooling device and fanless technology, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of high water pressure requirements, poor atomization effect, etc., to reduce maintenance costs, Energy saving and enhanced cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

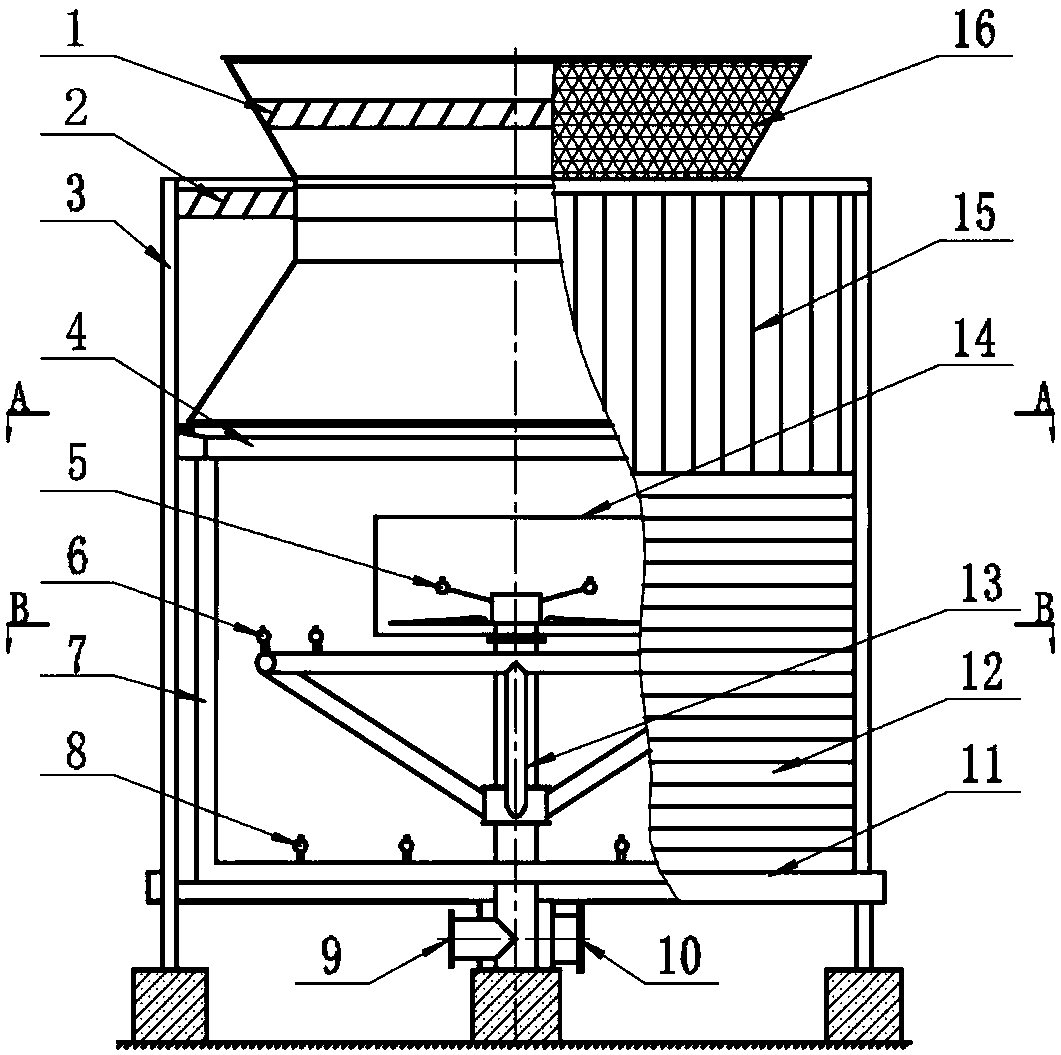

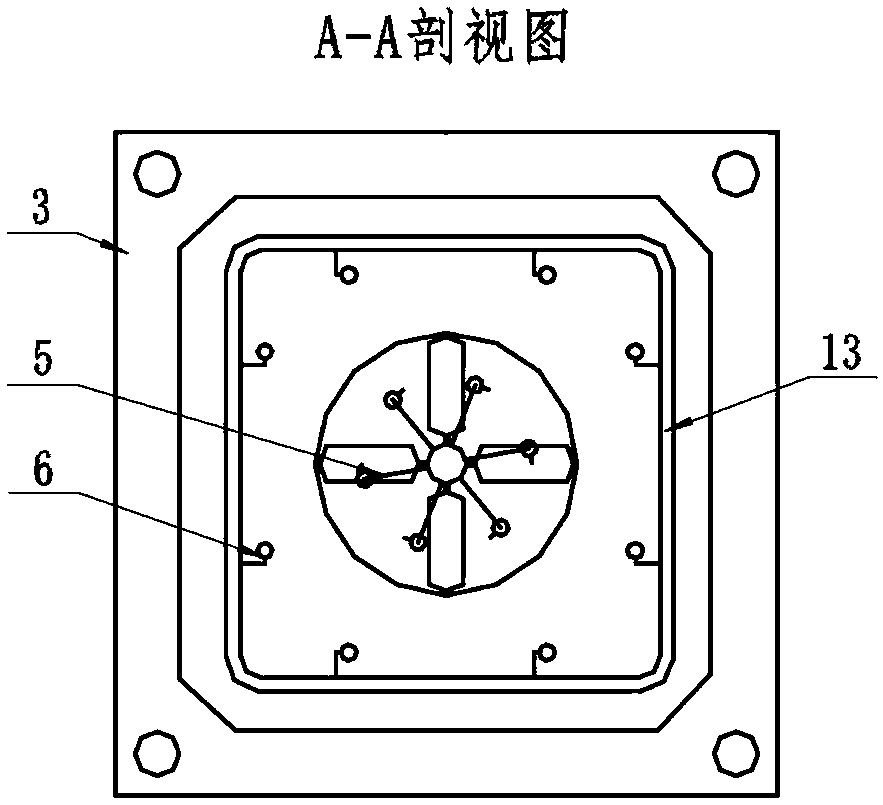

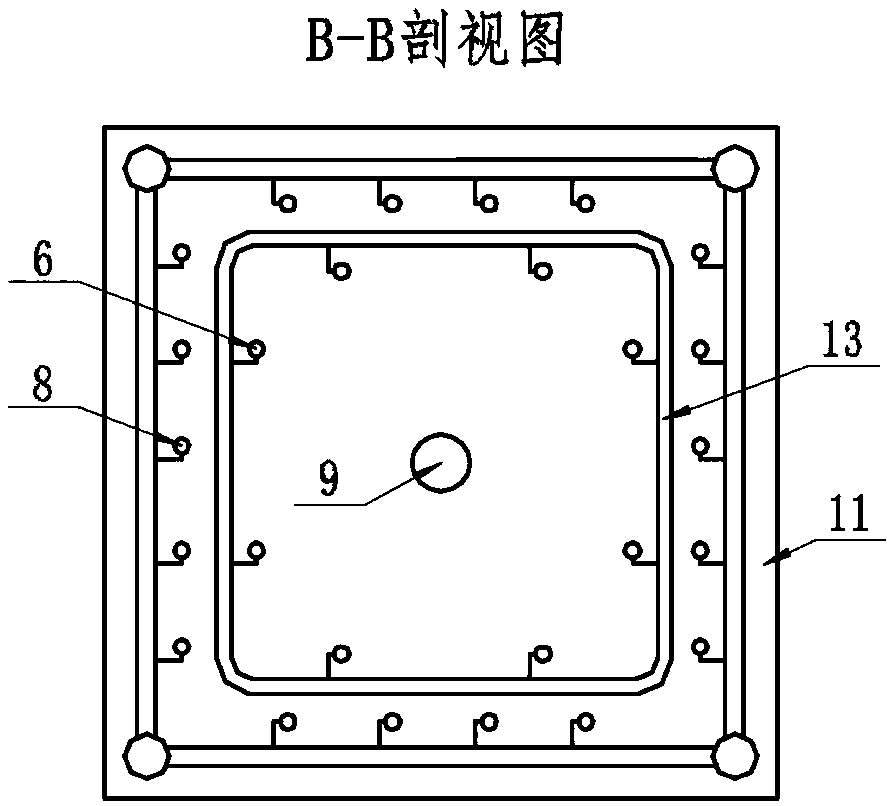

[0042] Such as Figure 1-Figure 3 As shown, the multi-stage jet spray gravity return water fan and filler-free cooling device provided by this embodiment is provided with a middle-stage fixed low-pressure swirl atomization nozzle assembly 6 and a bottom-stage gravity return low-pressure swirl atomization nozzle Component 8.

[0043] The intermediate stage fixed low-pressure swirling atomization nozzle assembly 6 is located in the middle of the tower, and the low-pressure jet sprays the temperature, and it has the effect of jet atomization and air extraction to ensure a high water density of the whole tower. The bottom stage gravity return water low pressure swirl atomization nozzle assembly 8 is at the bottom of the tower, the full-wire mesh convergent expansion type outlet tube 16 collects water to the sump 4, and the downpipe 7 is connected to the bottom stage gravity return water low pressure swirl atomization nozzle The component 8 is sprayed to cool down again to enhance th...

Embodiment 2

[0046] Such as Figure 4 As shown, the multi-stage jet spray gravity backwater fan and filler-free cooling device provided by this embodiment is connected to the lower side of the middle-stage fixed low-pressure swirl atomization nozzle assembly 6 through the water distribution pipe 13 to the middle-stage second-layer fixed low-pressure swirl Flow atomization nozzle assembly 17.

[0047] The second-layer fixed low-pressure swirl atomization nozzle assembly 17 and the middle-level fixed low-pressure swirl atomization nozzle assembly 6 distribute the required number of nozzles, calibers and angles, etc., which can effectively increase and adjust the total tower water intake, that is, the spray density. Solve the shortcomings and disadvantages of the traditional spray cooling tower that the single-layer nozzle arrangement is insufficient and the water distribution is too concentrated.

[0048] During the implementation of this embodiment, two or more middle-level fixed low-pressure sw...

Embodiment 3

[0051] Such as Figure 5 As shown, the multi-stage jet spray gravity return water fan and filler-free cooling device provided by this embodiment is connected to the bottom stage second layer gravity through a water distribution pipe 13 on the upper side of the bottom stage gravity return water low-pressure swirl atomization nozzle assembly 8 Return water low-pressure swirling atomization nozzle assembly 18. The bottom-level second-level gravity backwater low-pressure swirl atomization nozzle assembly 18, together with the bottom-level gravity backwater low-pressure swirl atomization nozzle assembly 8, distributes the required number of nozzles, caliber and angle, etc., which can effectively increase and adjust the entire tower The gravity return water volume of the sump 4 makes full use of the space at the bottom of the tower body, effectively increases the cooling range of the bottom of the tower, and increases the cooling performance.

[0052] During the implementation of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com