Plasma gas sensor and manufacturing method thereof

A gas sensor and plasma technology, applied in the field of ions, can solve the problems of reduced working voltage, signal instability, and easy generation of electric field shielding effects, etc., and achieve the effect of reduced working voltage and improved capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

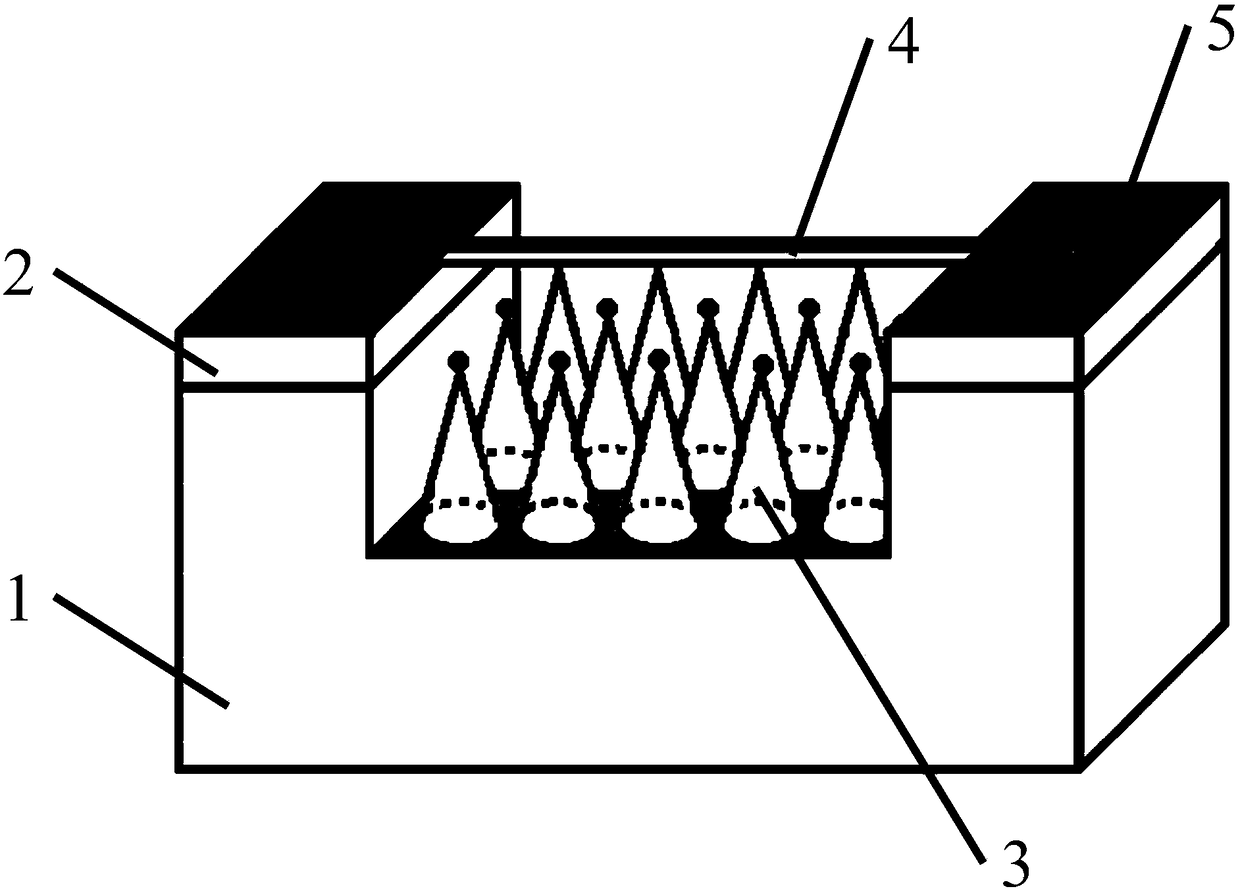

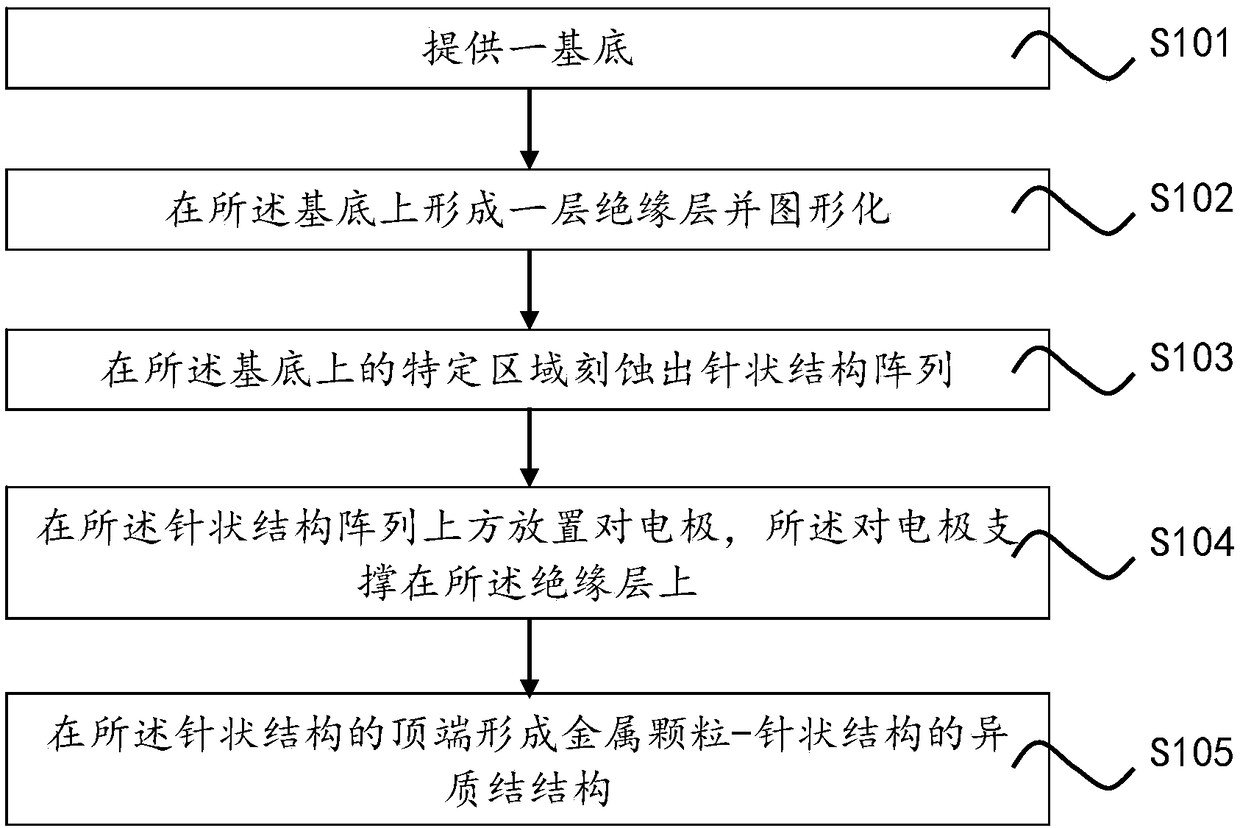

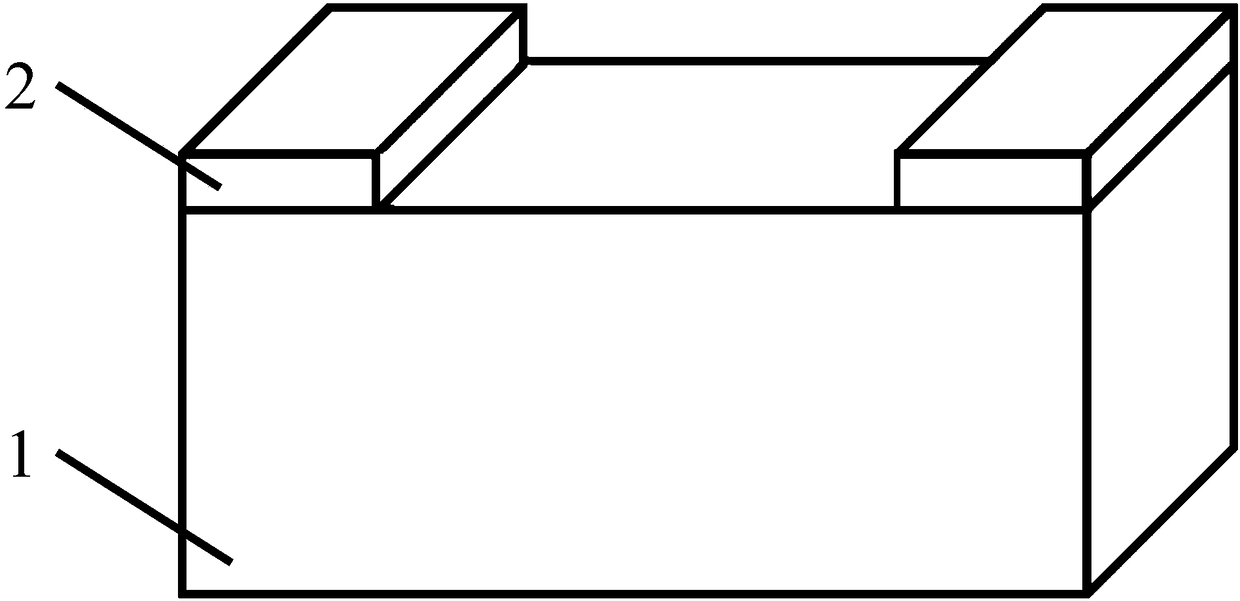

[0037] The plasma gas sensor and its manufacturing method proposed by the present invention will be further described in detail below with reference to the drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0038] Before proposing the present invention, the inventor of the present application has carried out sufficient research to the present possible plasma gas sensor, and concrete research is as follows:

[0039] 1) The electrode size of the reported plasma gas sensor is at the macroscopic level of millimeters or above. Since it is difficult to achieve absolute parallelism and consistency in the microscopic structure, the functional area that actually generates gas di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com