In-situ luminous flux monitoring and exposure dose compensating method

A technology of exposure dose and compensation method, which is applied in microlithography exposure equipment, photolithography exposure equipment, optics, etc., can solve problems affecting luminous flux, optical element deformation, device performance, etc., to improve device performance and nanostructure uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

[0025] The present invention is an in-situ luminous flux monitoring and exposure dose compensation method, comprising the following steps:

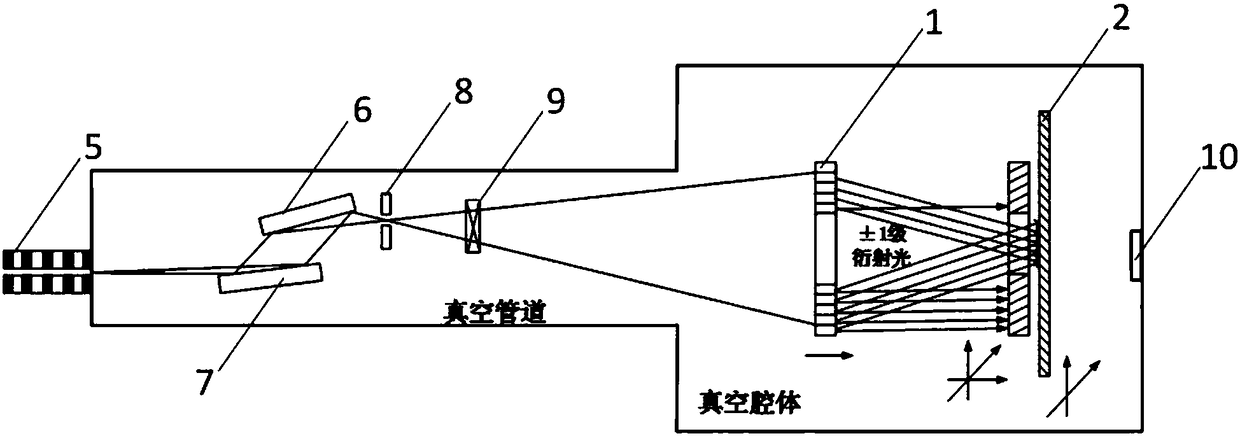

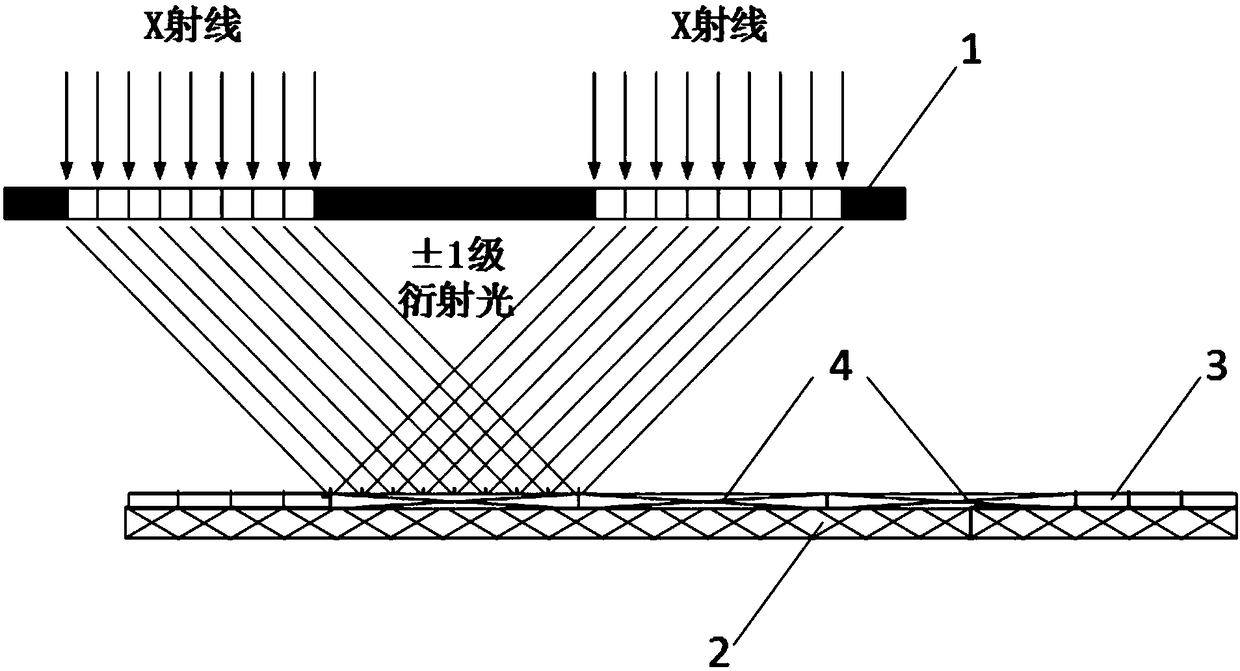

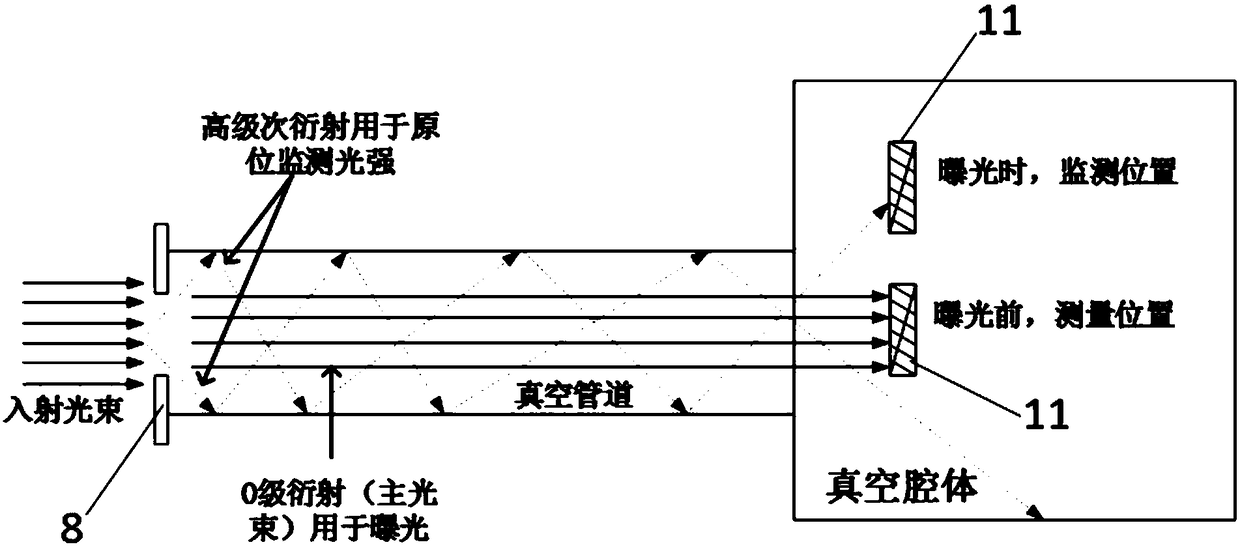

[0026] Step S1, using the existing synchrotron radiation X-ray large-area interference lithography system (such as figure 1 As shown) before performing the X-ray interference lithography experiment, firstly, adjust the incident light beam (i.e., X-ray) to make its intensity evenly distributed on the mask grating 1, and set a photodiode 11 upstream of the mask grating 1 in the vacuum chamber, And make it outside the main optical path generated by the incident beam (such as image 3 As shown, the photodiode 11 is in the monitoring position at this time), the first photocurrent is measured by an ammeter (not shown) connected with the photodiode 11, and then the first luminous flux Fsu is calculated and obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com