Manufacturing method for polypyrrole cladded copper nanowire with high SPR effect

A technology of copper nanowires and polypyrrole, applied in nanotechnology for sensing, nanotechnology for materials and surface science, nanotechnology, etc., can solve the difficulty of increasing the cost of copper nanowire preparation and mass production , high temperature, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

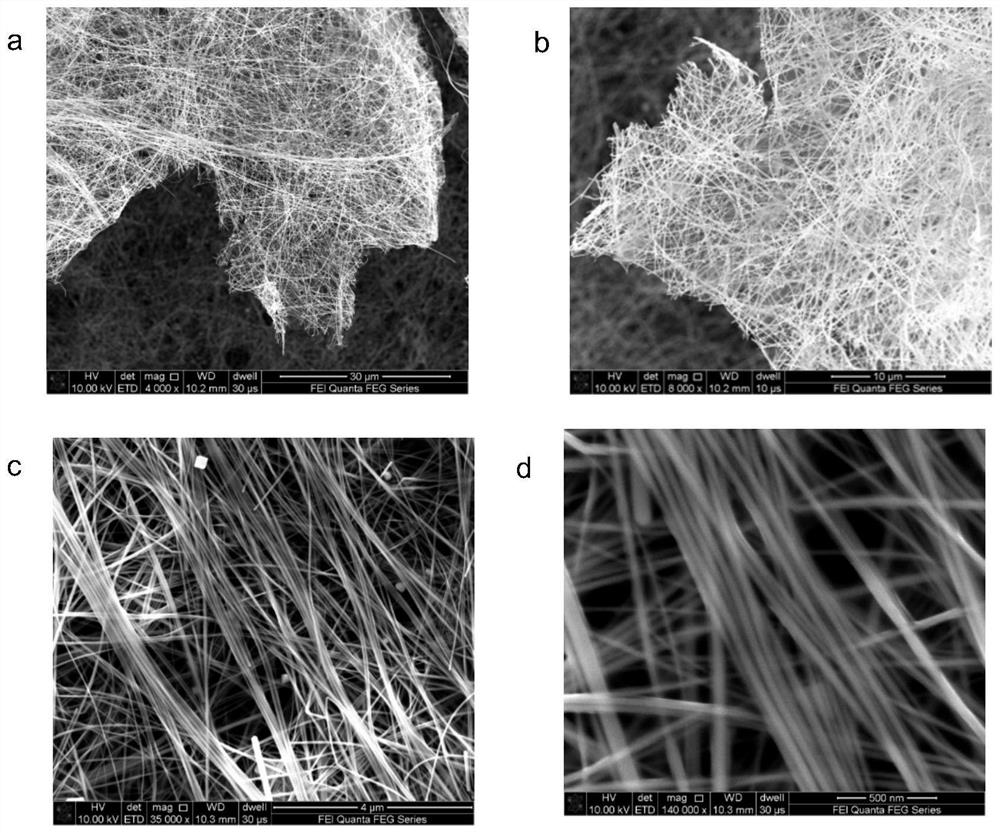

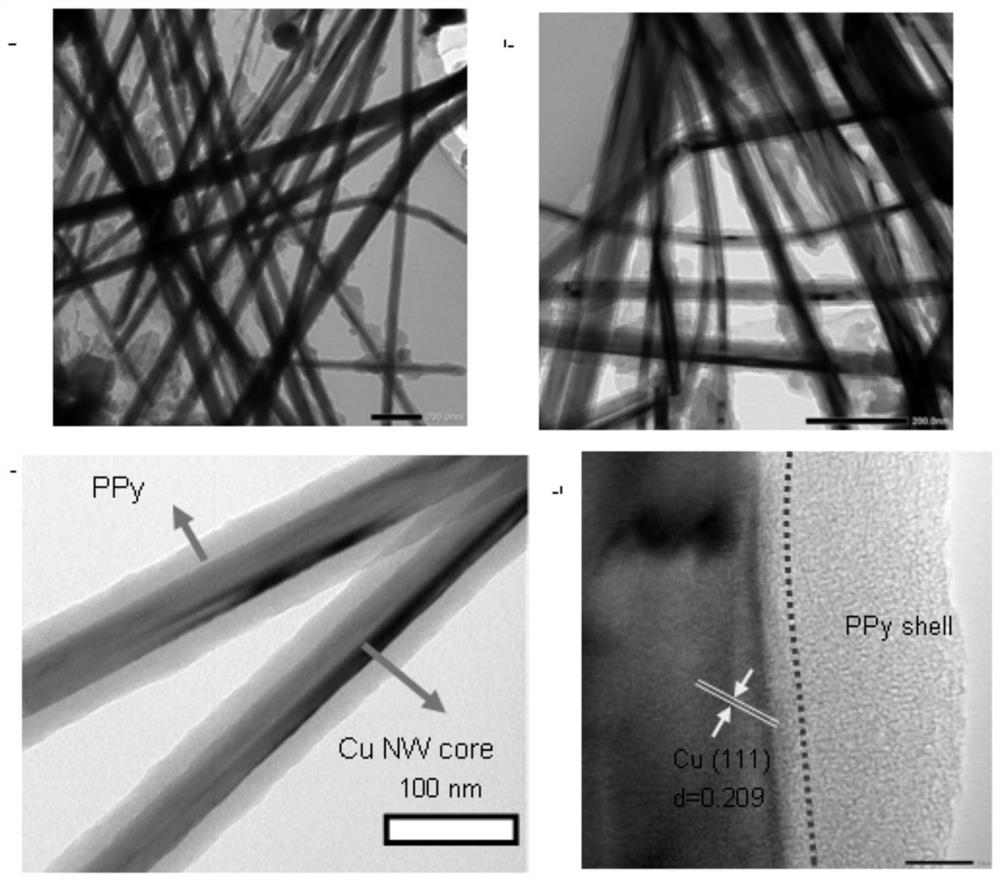

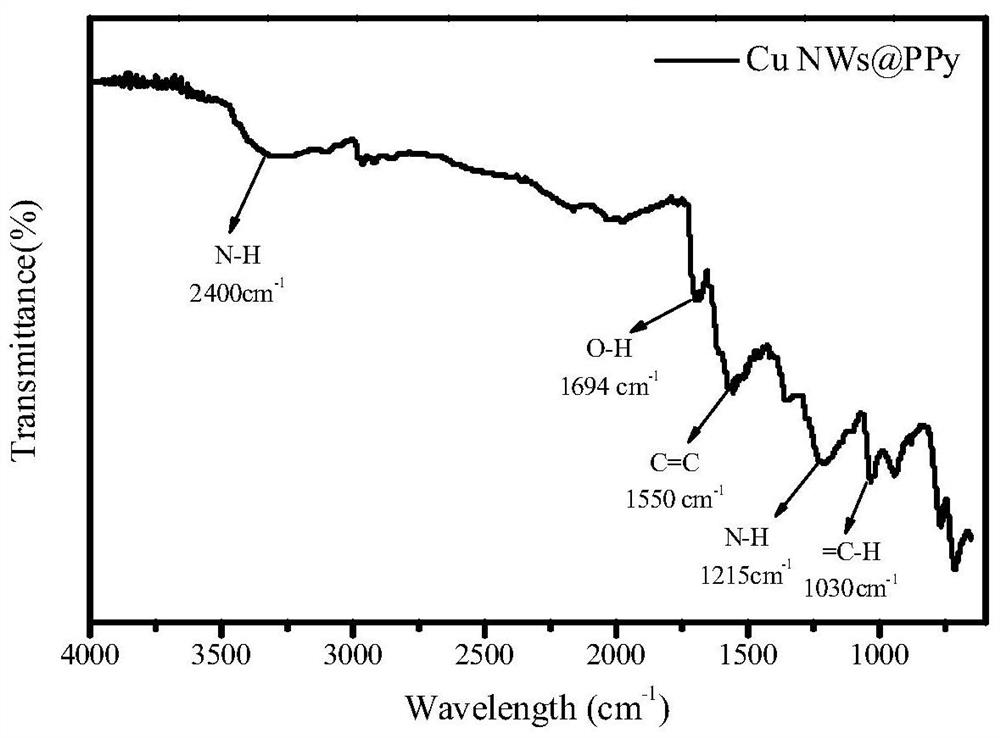

[0022] The polypyrrole-wrapped copper nanowire preparation method with high SPR effect of the present invention comprises the following steps:

[0023] Prepare copper nanowires by hydrothermal method, then disperse copper nanowires in the reagent, then add pyrrole, then add deionized water, and finally add hydrogen peroxide, stir and centrifuge and wash with water to obtain polypyrrole coating with high SPR effect copper nanowires.

[0024] The reagent is ethanol.

[0025] The ratio of copper nanowires, ethanol, pyrrole, deionized water and hydrogen peroxide is: 20mg: 2mL: 1000μL: 40mL: 100μL.

[0026] The stirring speed is 400r / min, the stirring time is 12h, and the washing times are three times.

[0027] The specific process of preparing copper nanowires by hydrothermal method is as follows:

[0028] Weigh CuCl 2 2H 2 O, glucose, octadecylamine, hexadecylamine, polyvinylpyrrolidone and deionized water, mixed and stirred, then poured into a polytetrafluoroethylene autocl...

Embodiment 2

[0033] The polypyrrole-wrapped copper nanowire preparation method with high SPR effect of the present invention comprises the following steps:

[0034] Prepare copper nanowires by hydrothermal method, then disperse copper nanowires in the reagent, then add pyrrole, then add deionized water, and finally add hydrogen peroxide, stir and centrifuge and wash with water to obtain polypyrrole coating with high SPR effect copper nanowires.

[0035] The reagent is ethanol.

[0036] The ratio of copper nanowires, ethanol, pyrrole, deionized water and hydrogen peroxide is: 20mg: 2mL: 50μL: 40mL: 5μL.

[0037] The stirring speed is 400r / min, the stirring time is 12h-48h, and the washing times are three times.

[0038] The specific process of preparing copper nanowires by hydrothermal method is as follows:

[0039] Weigh CuCl 2 2H 2 O, glucose, octadecylamine, hexadecylamine, polyvinylpyrrolidone and deionized water, mixed and stirred, then poured into a polytetrafluoroethylene autocl...

Embodiment 3

[0043] The polypyrrole-wrapped copper nanowire preparation method with high SPR effect of the present invention comprises the following steps:

[0044] Prepare copper nanowires by hydrothermal method, then disperse copper nanowires in the reagent, then add pyrrole, then add deionized water, and finally add hydrogen peroxide, stir and centrifuge and wash with water to obtain polypyrrole coating with high SPR effect copper nanowires.

[0045] The reagent is ethanol.

[0046] The ratio of copper nanowires, ethanol, pyrrole, deionized water and hydrogen peroxide is: 100mg: 2mL: 2000μL: 40mL: 500μL.

[0047] The stirring speed is 400r / min, the stirring time is 48h, and the washing times are three times.

[0048] The specific process of preparing copper nanowires by hydrothermal method is as follows:

[0049] Weigh CuCl 2 2H 2 O, glucose, octadecylamine, hexadecylamine, polyvinylpyrrolidone and deionized water, mixed and stirred, then poured into a polytetrafluoroethylene autocla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com