Sodium ion battery anode, preparation method thereof and sodium ion battery

A sodium-ion battery and negative electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of red phosphorus composite materials with low tap density, low energy density and power density, and poor high-current charge and discharge capabilities and other issues, to achieve the effect of industrial production properties, high tap density, and good high-current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. The preparation method of the negative electrode of the sodium ion battery of the present embodiment comprises the following steps:

[0050] Preparation of nano-red phosphorus material: high-energy ball milling method is used to ball-mill the block commercial red phosphorus to nanometer size. The mass ratio of the block red phosphorus is 50:1, the speed is 800rpm, the ball-milling time is 12h, and it is carried out under an inert atmosphere. Ball milling, in order to prevent the temperature of the ball milling process from being too high, the ball milling was performed for 5 minutes with an interval of 5 minutes.

[0051] Preparation of nano-red phosphorus and graphene composite materials: use high-energy ball milling method to compound a certain proportion of nano-red phosphorus and graphene, and mix nano-red phosphorus and graphene according to the mass ratio of 2:1, the speed is 500rpm, and the ball milling time is 500rpm. For 5 hours, ball milling was carried out...

Embodiment 2

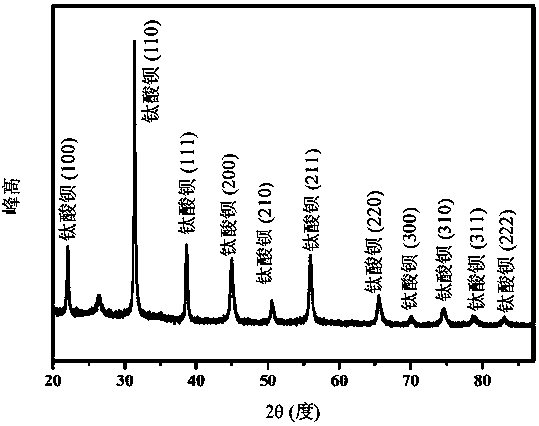

[0058] The preparation method of nano-red phosphorus, barium titanate and graphene composite material and the method of coating the pole piece (i.e. the negative electrode of sodium ion battery) are the same as in Example 1, except that the surface of the pole piece is coated with 10 circles of di Aluminum, the specific process is that the aluminum source is trimethylaluminum, the oxygen source is water, the temperature of the reaction chamber is 150°C, and the number of reaction cycles is 10.

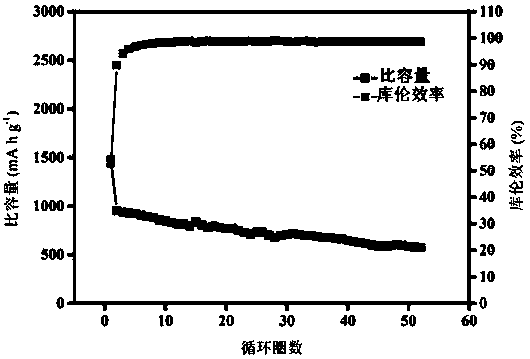

[0059] The electrochemical performance test is the same as in Example 1. at 2A·g -1 Charge and discharge tests are performed at high current densities. The test results show that the composite material exhibits extremely high mass specific capacity and cycle stability even under large rate conditions. For example, the initial discharge capacity can reach 1190mAh·g -1 , and the initial Coulombic efficiency reaches 64%. Even after 50 cycles of high current charge and discharge, the c...

Embodiment 3

[0061] The preparation method of nano-red phosphorus, barium titanate and graphene composite material and the method for preparing pole pieces by coating film are the same as in Example 1, and the process of coating aluminum oxide with ALD technology is the same as in Example 2, except that the prepared battery pole The barium titanate in the sheet continues to undergo polarization treatment. The pole piece is placed between two parallel copper electrodes for insulation treatment, and 8kv DC voltage is applied, and polarization treatment is carried out at room temperature for 24h.

[0062] The electrochemical performance test is the same as in Example 1. at 2A·g -1 Charge and discharge tests are performed at high current densities. The test results show that the composite material exhibits extremely high mass specific capacity and cycle stability even under large rate conditions. For example, the initial discharge capacity can reach 925mAh·g -1 , and the initial Coulombic e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com