A method and device for extracting and rectifying separation of cyclohexanol and n-hexanol

A technology for extractive rectification and extractive rectification tower, which is applied in the field of extractive rectification and separation of cyclohexanol and n-hexanol, can solve the problems of high cyclohexanol content, difficulty in separating cyclohexanol and n-hexanol, and difficulty in separation, and achieves a simple process. , improve the effective utilization rate and reduce the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

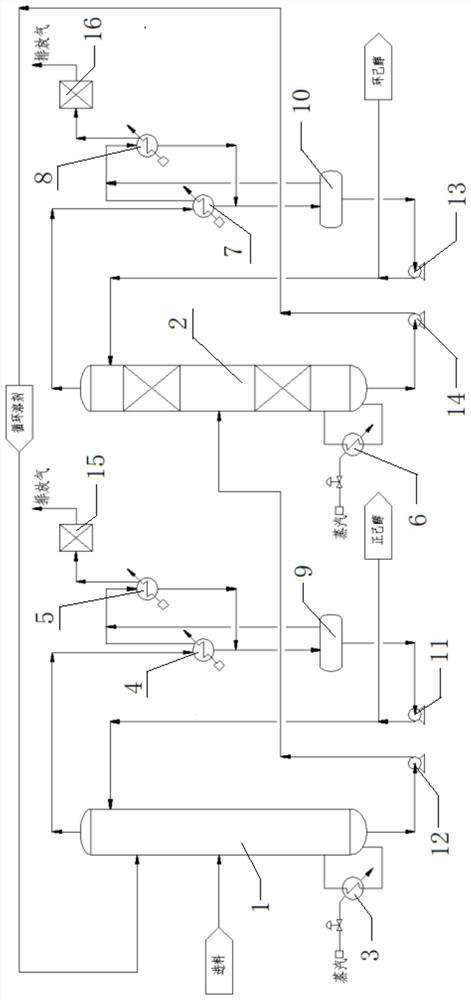

[0035] Extractive distillation separation process of cyclohexanol and n-hexanol, such as figure 1 shown. The extractive distillation column 1 has 35 theoretical plates. Use glycerol as the extractant, add from the fourth theoretical plate (the number of plates is from top to bottom), the addition amount is 5000kg / hr, cyclohexanol and n-hexanol are added from the 12th plate in the middle of the tower, the total flow rate is 5000kg / hr, wherein the mass fraction of cyclohexanol is 88wt%. The operating pressure of the extractive distillation tower is 5kPaA, the top reflux ratio is 2.0, the top temperature is 83.1°C, the bottom temperature is 101.3°C, and the n-hexanol product with a mass fraction of 99.6wt% is obtained at the top of the tower.

[0036] The mixture of cyclohexanol and glycerol in the tower kettle is sent to the solvent recovery tower 2, the operating pressure at the top of the tower is 5kPaA, the reflux ratio at the top of the tower is 1.0, the temperature at th...

Embodiment 2

[0038] Extractive distillation separation process of cyclohexanol and n-hexanol, such as figure 1 shown. Extractive distillation column, 1 has 35 theoretical plates. Use glycerol as the extractant, add from the 4th theoretical plate (the number of plates is from top to bottom), the addition amount is 7000kg / hr, cyclohexanol and n-hexanol are added from the 12th plate in the middle of the tower, the total flow rate is 5000kg / hr, wherein the mass fraction of cyclohexanol is 85wt%. The operating pressure of the extractive distillation tower is 5kPaA, the top reflux ratio is 1.0, the top temperature is 83.1°C, the bottom temperature is 105.6°C, and the n-hexanol product with a mass fraction of 99.8wt% is obtained at the top of the tower.

[0039] The mixture of cyclohexanol and glycerol in the tower kettle is sent to the solvent recovery tower 2, the operating pressure at the top of the tower is 5kPaA, the reflux ratio at the top of the tower is 1.0, the temperature at the top ...

Embodiment 3

[0041] Extractive distillation separation process of cyclohexanol and n-hexanol, such as figure 1 shown. The extractive distillation column 1 has 35 theoretical plates. Use glycerol as the extractant, add from the fourth theoretical plate (the number of plates is from top to bottom), the addition amount is 5000kg / hr, cyclohexanol and n-hexanol are added from the 12th plate in the middle of the tower, the total flow rate is 5000kg / hr, wherein the mass fraction of cyclohexanol is 82wt%. The operating pressure of the extractive distillation tower is 5kPaA, the top reflux ratio is 1.0, the temperature at the top of the tower is 83.1°C, and the temperature at the bottom of the tower is 101.1°C. The n-hexanol product with a mass fraction of 99.1wt% is obtained at the top of the tower.

[0042] The mixture of cyclohexanol and glycerol in the tower kettle is sent to the solvent recovery tower 2, the operating pressure at the top of the tower is 5kPaA, the reflux ratio at the top of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com