Composite phase change heat storage material using edible fungus charcoal as shaping matrix and preparation method

A heat storage material and composite phase change technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy flow and low thermal conductivity of phase change, and achieve the effect of enhancing heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

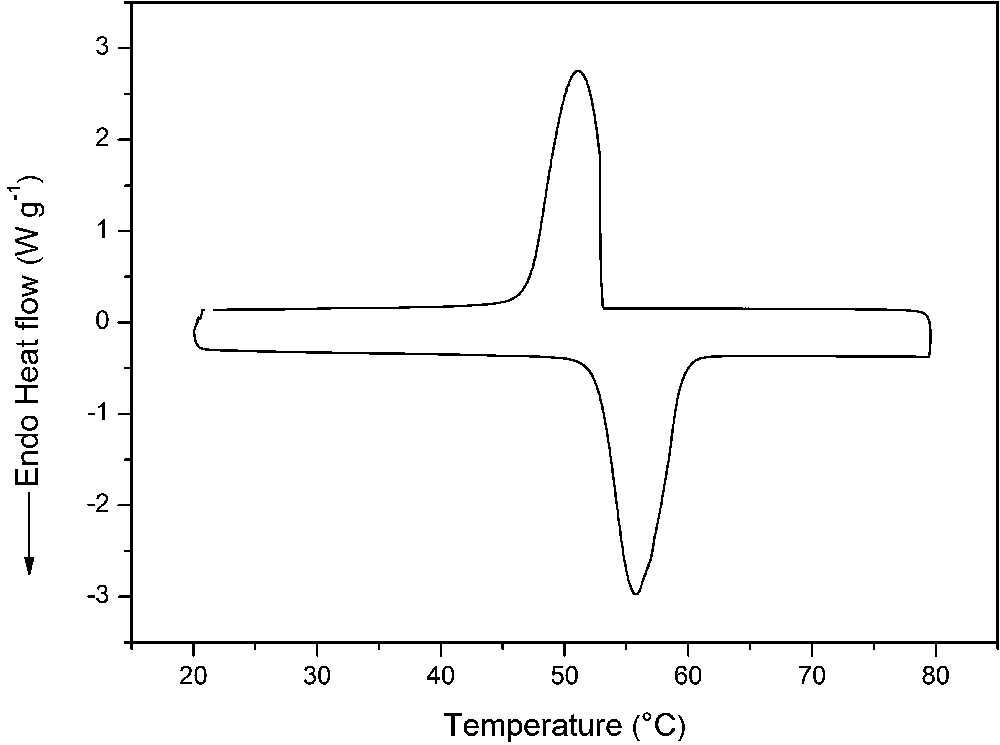

[0024] Weigh 10g of dried fungus in deionized water, soak at room temperature for 2h, put the soaked fungus and 200ml of deionized water into a polytetrafluoroethylene-lined high-pressure stainless steel hydrothermal reaction kettle, and react at 180°C for 24h to obtain Sepia powder, washed and dried many times to get hydrothermal carbonized fungus; mix hydrothermal carbonized fungus with KOH in a ratio of 1:3, put it in a vacuum tube furnace, and react at 800°C for 2 hours under Ar atmosphere. After the reaction is completed , the obtained primary product is washed and dried several times to obtain the fungus charcoal base material; the stearic acid and the fungus charcoal base material are mixed evenly at 4:1 and placed in the conical flask reaction container, and the vacuum device is opened to make the pressure in the container reach- After 0.05MPa, move the reaction vessel to a heating type ultrasonic cleaner and maintain it at 90°C for 20 minutes. After the reaction is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com