Anti-wear, anti-friction and anti-oxidant additive and energy-saving hydraulic oil containing same

A technology of hydraulic oil and additives, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of reducing friction, large motion resistance, thinning of lubricating oil film, etc., to prolong the service life of machinery, prevent sintering accidents, resist Good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

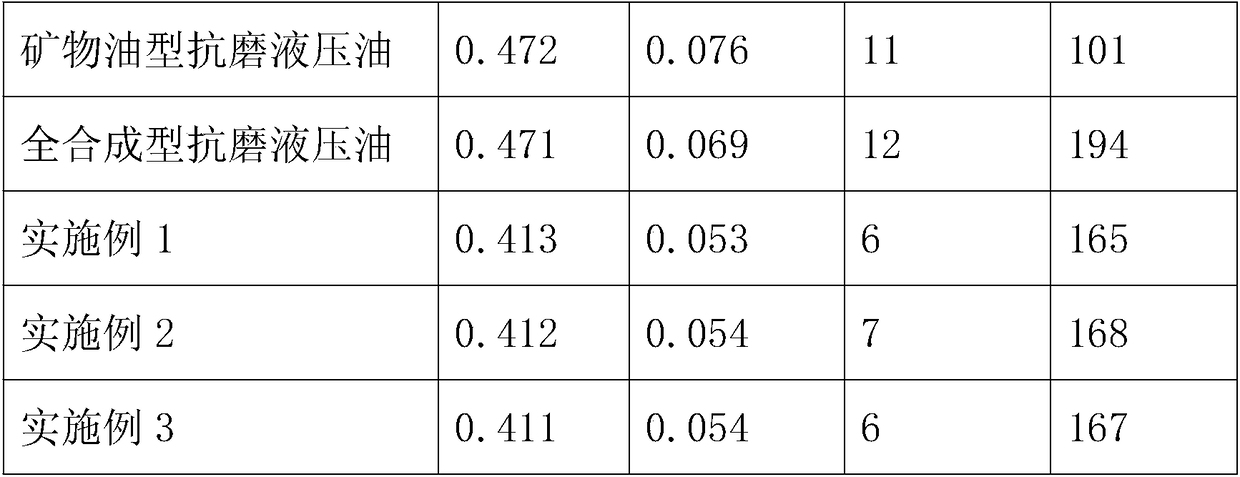

Embodiment 1

[0023] An anti-wear, anti-friction and anti-oxidation additive, the raw materials of which are as follows in parts by weight: 5 parts of zinc dialkyl thiosulfate, 2 parts of molybdenum phosphate, 2 parts of molybdenum dithiocarbamate, 3 parts of boron nitrogen compound, boric acid 10-parts of salt, 5 parts of organic molybdenum, 7 parts of methylene bis-dibutyldithiocarbamate, 5 parts of polyisobutylene bis-succinimide.

[0024] An energy-saving hydraulic oil, comprising 4 parts of anti-wear, anti-friction and anti-oxidation additives in claim 1, 12 parts of 350N paraffin base oil, 815 parts of polyalphaolefin PAO, and 3 parts of polyol ester, and is prepared according to the following steps :

[0025] S1: zinc dialkyl thiosulfate, molybdenum phosphate, molybdenum dithiocarbamate, boron nitrogen compound, borate, organic molybdenum, methylene bis-dibutyl dithiocarbamate, polyisobutylene bis Succinimide, 350N paraffin base oil, polyalphaolefin PAO8 and polyol ester are weighed...

Embodiment 2

[0039] An anti-wear, anti-friction and anti-oxidant additive, the raw materials of which are as follows in parts by weight: 6 parts of zinc dialkyl thiosulfate, 3 parts of molybdenum phosphate, 2 parts of molybdenum dithiocarbamate, 4 parts of boron nitrogen compound, boric acid 11 parts of salt, 5 parts of organic molybdenum, 8 parts of methylene bis-dibutyl dithiocarbamate, and 6 parts of polyisobutylene bis-succinimide.

[0040] An energy-saving hydraulic oil, comprising 5 parts of anti-wear, anti-friction and anti-oxidant additives in claim 1, 13 parts of 350N paraffin base oil, 17 parts of polyalphaolefin PAO, and 5 parts of polyol ester, and is prepared according to the following steps :

[0041] S1: zinc dialkyl thiosulfate, molybdenum phosphate, molybdenum dithiocarbamate, boron nitrogen compound, borate, organic molybdenum, methylene bis-dibutyl dithiocarbamate, polyisobutylene bis Succinimide, 350N paraffin base oil, polyalphaolefin PAO8 and polyol ester are weighed...

Embodiment 3

[0055] An anti-wear, anti-friction and anti-oxidant additive, the raw materials of which are as follows in parts by weight: 7 parts of zinc dialkyl thiosulfate, 4 parts of molybdenum phosphate, 3 parts of molybdenum dithiocarbamate, 5 parts of boron nitrogen compound, boric acid 12 parts of salt, 6 parts of organic molybdenum, 10 parts of methylene bis-dibutyl dithiocarbamate, 7 parts of polyisobutylene bis-succinimide.

[0056] An energy-saving hydraulic oil, comprising 6 parts of anti-wear, anti-friction and anti-oxidation additives in claim 1, 15 parts of 350N paraffin base oil, 820 parts of polyalphaolefin PAO, and 7 parts of polyol ester, and is prepared according to the following steps :

[0057] S1: zinc dialkyl thiosulfate, molybdenum phosphate, molybdenum dithiocarbamate, boron nitrogen compound, borate, organic molybdenum, methylene bis-dibutyl dithiocarbamate, polyisobutylene bis Succinimide, 350N paraffin base oil, polyalphaolefin PAO8 and polyol ester are weighed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com