A rotating shaft angle and speed measuring device

A speed measurement and angle technology, applied in the field of rotating shaft motion parameter measurement equipment, can solve the problems of inability to output correct speed and angle signals, inability to meet sine/cosine signal interpolation, uneven chip induction sensitivity, etc., to achieve measurement accuracy and sensitivity. The effect of improving, stable and balanced work performance, and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

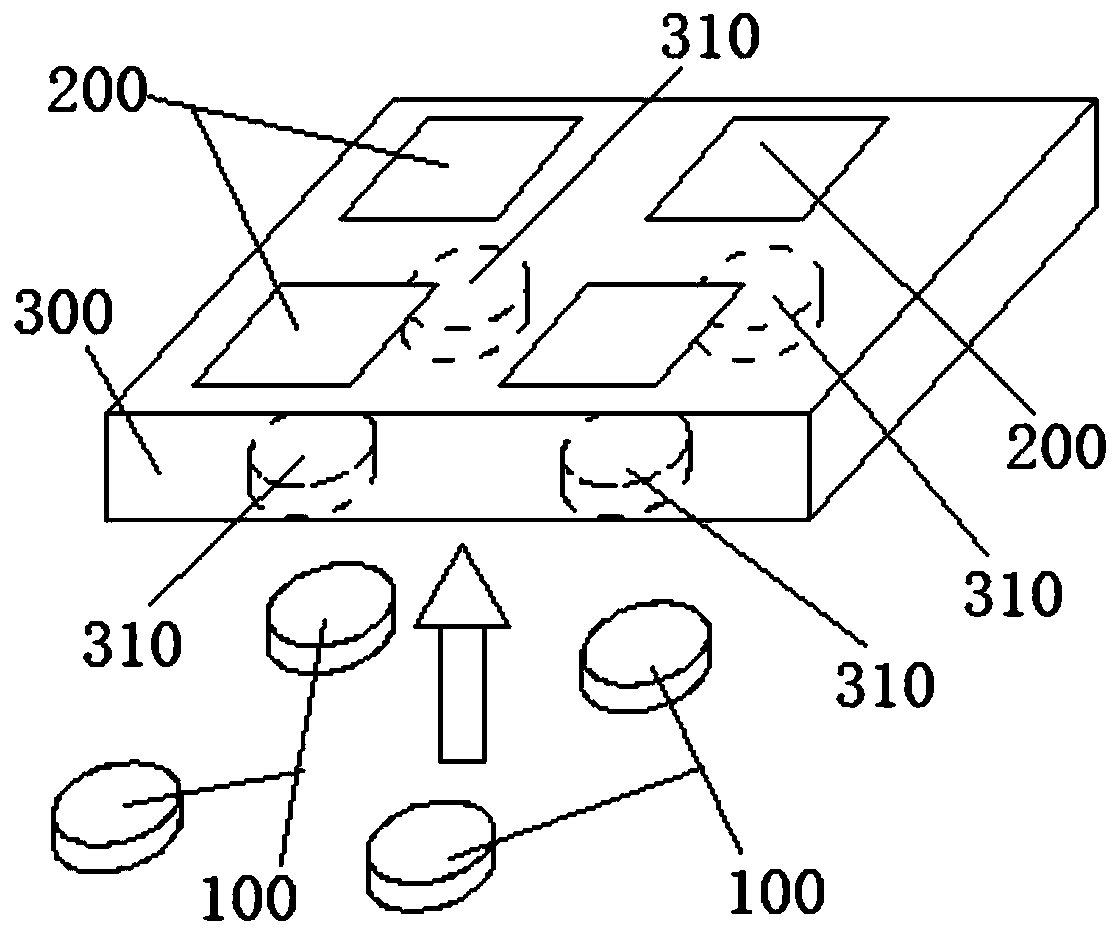

[0039] image 3 As shown, the present invention provides a rotating shaft angle and speed measuring device, including a permanent magnet 100, a chip 200 integrated with a magnetoresistive sensor, and a PCB circuit board 300; the upper end surface of the PCB circuit board 300 is electrically connected. There are a plurality of chips 200; the lower end surface of the PCB circuit board is provided with a plurality of counterbores 310 whose shape is adapted to the permanent magnet; the axis of each counterbore 310 passes through one of the chips respectively. 200 centroid; the permanent magnet 100 is firmly connected with the PCB circuit board 300 through the counterbore 310; Figure 4 As shown, the magnetoresistive sensor 210 is provided with: a first power supply connection terminal VCC1, a ground terminal GND, a first signal output terminal OUT+ and a second signal output terminal OUT-, the first signal output terminal OUT+ is connected in series with the first resistor R1 It ...

Embodiment 2

[0043] The present invention further improves the magnetoresistive sensor on the basis of Embodiment 1. Specifically, such as Figure 5 As shown, the magnetoresistive sensor 210 also includes: a first capacitor C1 and a second capacitor C2; the first signal output terminal OUT+ is output in series with the first capacitor C1; the output connection terminal of the first capacitor C1 is connected to The first resistor R1 is connected in series with the second power supply terminal VCC2; the output terminal of the first capacitor C1 is connected in series with the second resistor R2 and grounded to GND; the second signal output terminal OUT- is connected to the second capacitor C2 output in series; the output connection end of the second capacitor C2 is connected in series with the third resistor R3 and then electrically connected to the second power supply connection end VCC2; the output connection end of the second capacitor C2 is connected in series with the fourth resistor R4...

Embodiment 3

[0048] Since they are located on the same PCB circuit board, when multiple chips are electrically connected to the PCB circuit board, it is difficult to achieve the same distance between the chips and the PCB circuit board. There are still slight differences in the output accuracy. The present invention uses multiple double-sided adhesive films with a thickness of 0.01mm to realize the fast connection between the permanent magnet and the counterbore. By controlling the number of stacked double-sided adhesive films to achieve permanent The technical effect of the separation distance between the magnet and the chip. When assembling, choose chips with 2 or 3 double-sided adhesive films as the measurement reference, adjust the number of double-sided adhesive films that need to be stacked in the remaining counterbore, and then achieve the technology of fine-tuning the consistency of the signal output of each chip Effect. After adopting the above-mentioned structure, the working st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com