Building waste processing process and application of recycled fine aggregates and recycled sand obtained by building waste processing process

A technology for recycling fine aggregate and construction waste, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of performance not meeting industry standards, low utilization rate of construction waste, low strength and low water absorption and other problems, to achieve the effect of less surface wrapping, good water permeability and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

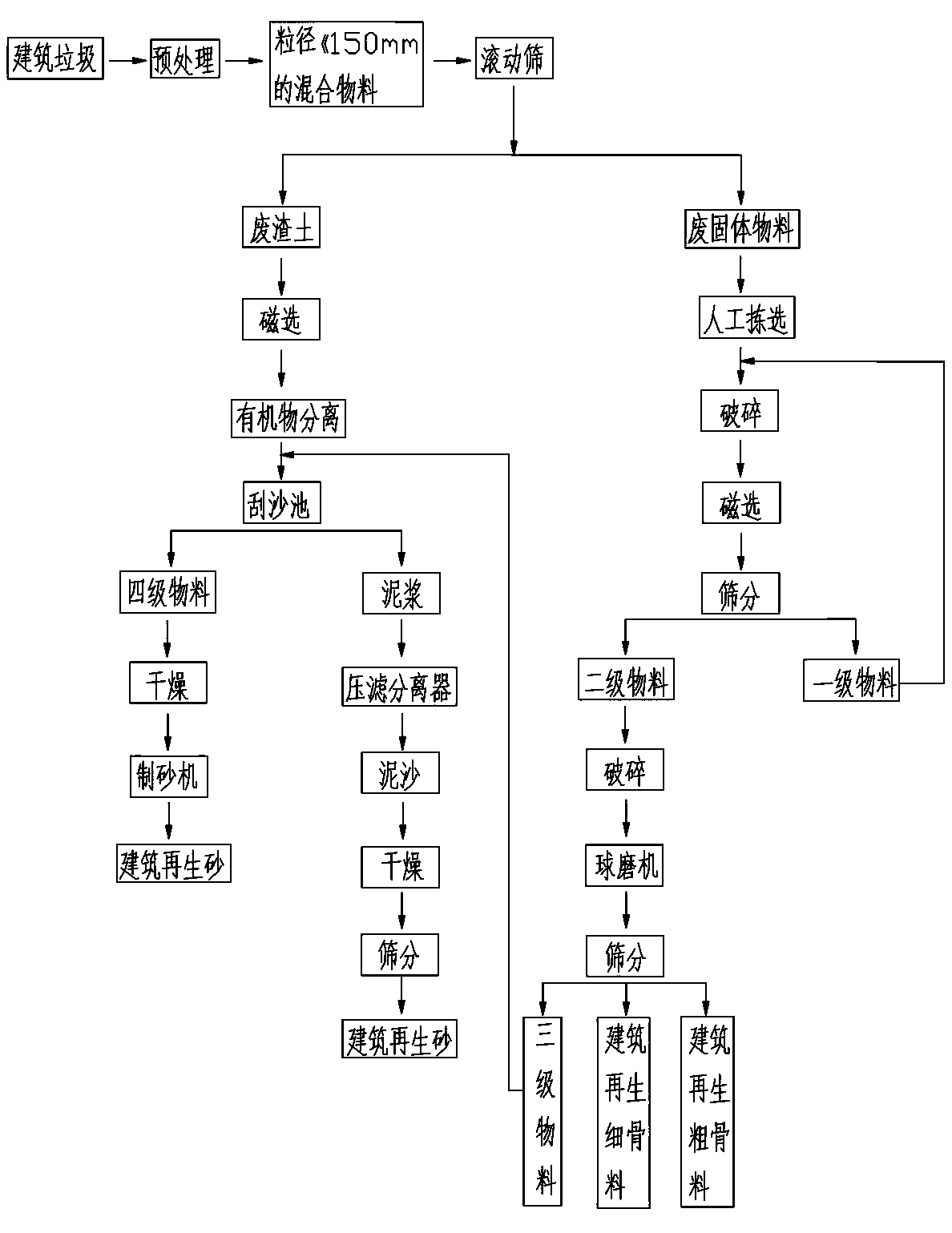

[0033] Such as figure 1 A construction waste treatment process is shown, which is used to separate, process and recycle mixed materials in construction waste, including the following steps:

[0034] (1) Pre-treat the construction waste and crush it to obtain a mixed material with a particle size below 150mm;

[0035] (2) Preliminarily screen the pretreated mixed material with a rolling sieve to separate the waste solid material and waste residue, and manually sort the waste solid material to remove fibers, plastics, broken glass, wires, steel bars and wood debris;

[0036] (3) The impurity-removed waste solid materials obtained in step (2) are sequentially crushed, magnetically separated, and screened to obtain primary materials with a particle size of 30 mm or more and secondary materials with a particle size of 30 mm or less;

[0037] (4) Repeat step (3) for the obtained primary materials until the obtained materials are all secondary materials with a particle size below 30...

Embodiment 2

[0054] An environmentally friendly permeable brick, the main components are recycled fine aggregate with a particle size of 1 to 5 mm and recycled sand with a particle size of 0.5 mm or less prepared in Example 1, and the mass components of the water seepage base are: recycled fine aggregate 40 parts of aggregate, 30 parts of recycled sand, 5 parts of fly ash, 15 parts of cement, 0.5 parts of water reducer, 13 parts of water; the mass components of the seepage surface layer are: 70 parts of recycled sand, 20 parts of cement, 7 parts of ash, 2 parts of mineral pigment, 0.5 part of water-permeable agent, 0.8 part of water-reducing agent, and 17 parts of water.

[0055] Its preparation process is as follows:

[0056] (1) Prepare cementitious base material and wet base material: Stir cement and water reducer evenly, add fly ash to mix to prepare cementitious base material; mix recycled fine aggregate and recycled sand evenly, add 3~ 5 parts water, mixed to make a wet base materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap