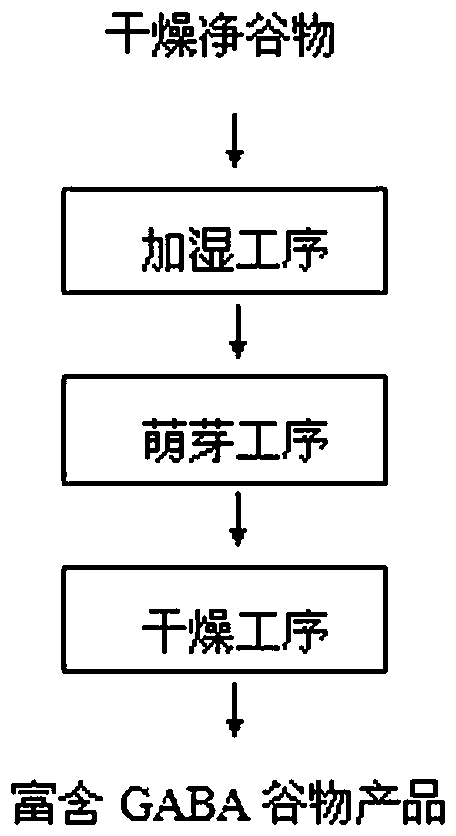

Production method and equipment of cereal rich in gamma-aminobutyric acid

A technology of aminobutyric acid and production method, applied in food science, preservation of seeds through drying, food drying, etc., can solve problems such as shortening the safe storage time or shelf life of germinated brown rice, deterioration of product appearance quality, and adverse effects on eating quality , to achieve the effect of reducing the lifting equipment, the method is simple, and the internal circulation of the equipment is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Figure 1~ Image 6 The figure of this embodiment 1 is shown.

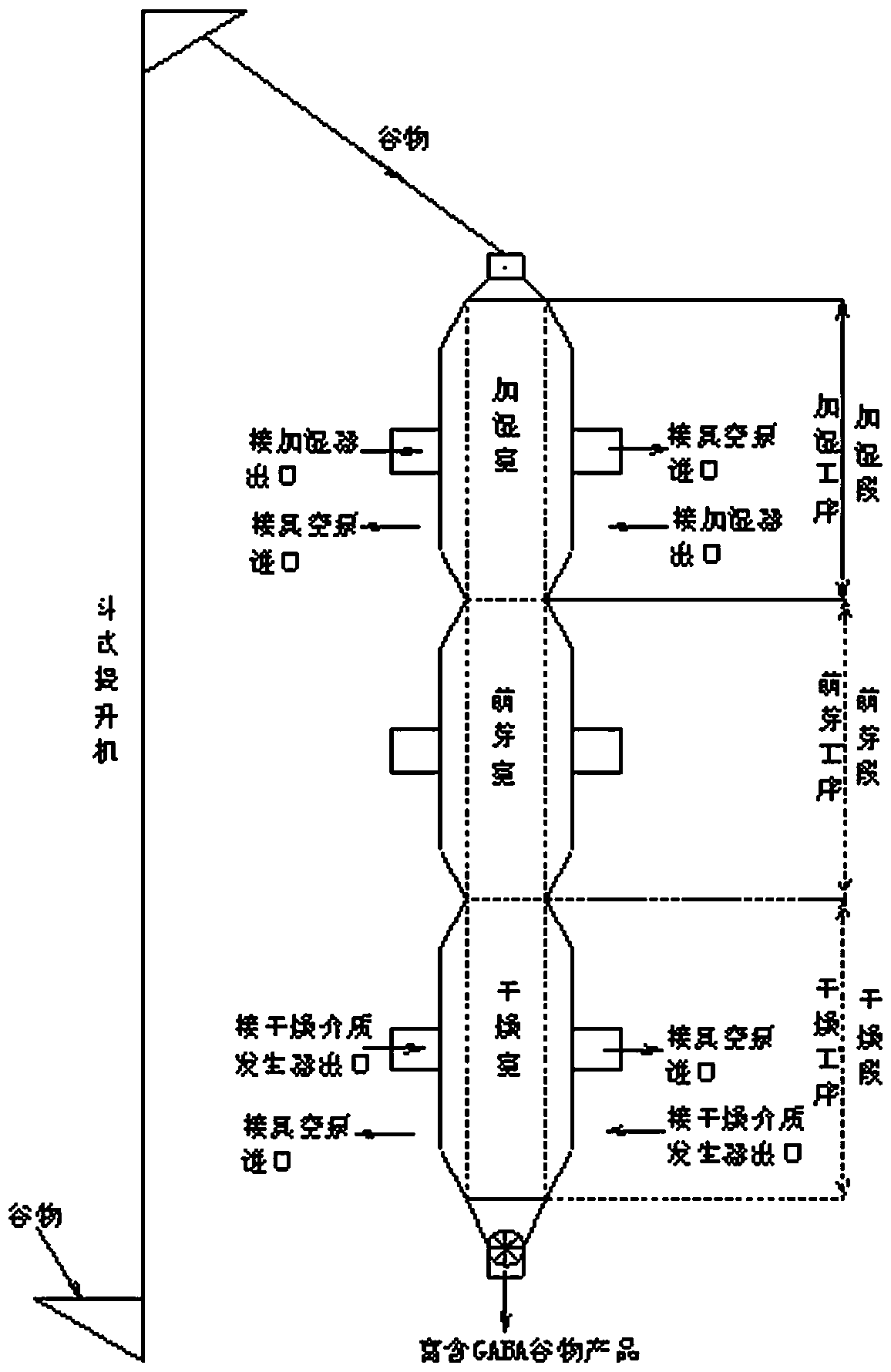

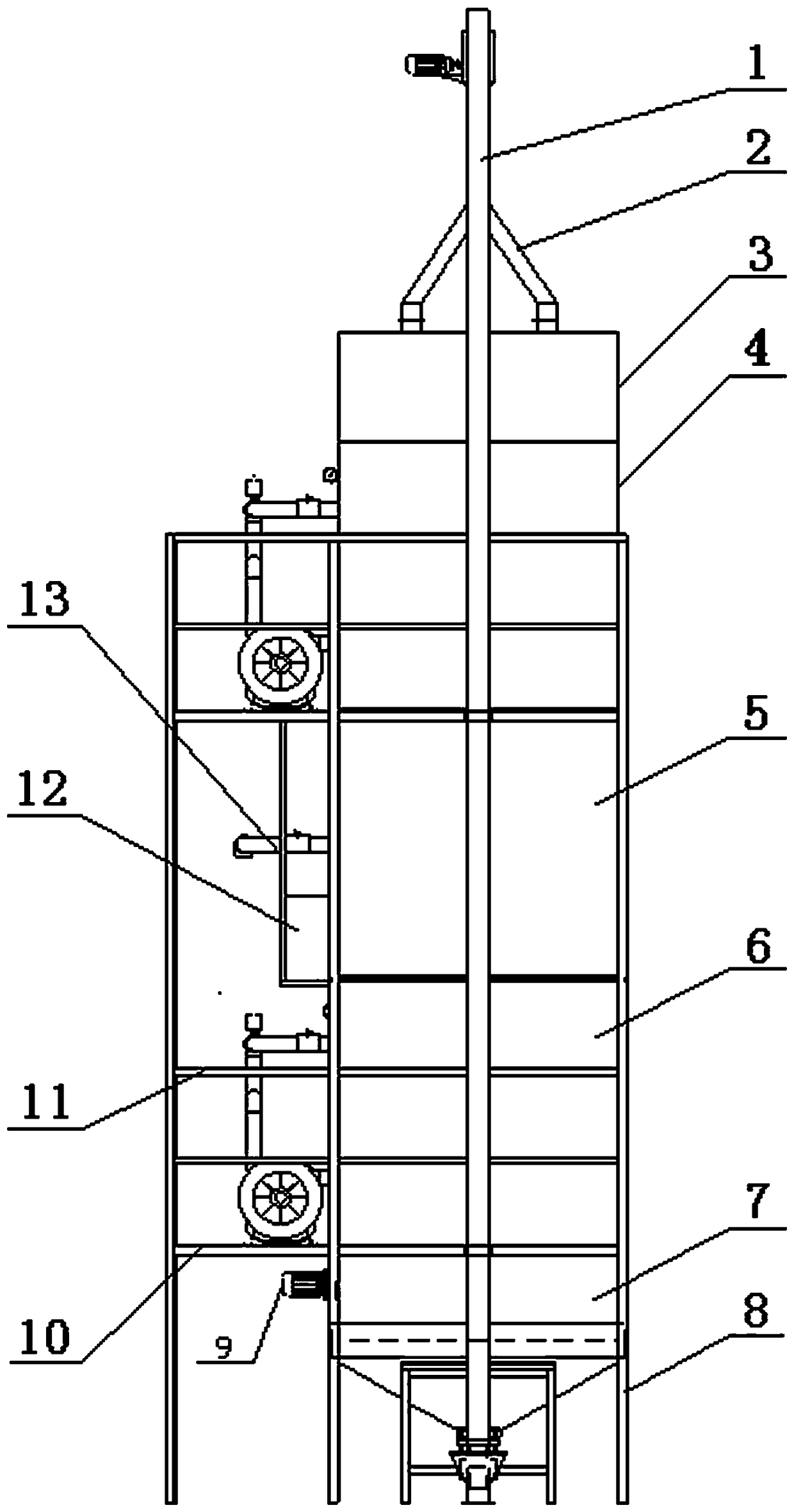

[0035] The GABA enrichment equipment of the present invention is arranged vertically on the main structure, and from top to bottom are the humidification chamber, the germination chamber and the drying chamber, and each chamber is connected up and down, so that the humidification chamber, the germination chamber and the drying chamber together constitute the grain self-contained Channels that flow from top to bottom. The GABA enrichment equipment of this example 1 adopts such as Figure 2 ~ Figure 6 Single channel version shown. Hereinafter, this embodiment 1 will be described in detail with a single channel type GABA enrichment device.

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the main body of the GABA enrichment equipment of this embodiment is divided into feeding section 3, humidification section 4, germination section 5, drying section 6, and discharging s...

Embodiment 2

[0061] figure 1 , Figure 7 , Picture 8 , Picture 9 Figure 2 of this embodiment is shown. The main structure and process conditions of the device in Example 2 are basically the same as those in Example 1, except that the GABA enrichment device adopts a dual-channel type. The advantage of the dual-channel type GABA enrichment equipment is that it can increase the production capacity per unit volume of equipment.

[0062] Such as figure 1 , Figure 7 , Picture 8 , Picture 9 As shown, the main difference between this embodiment 2 and embodiment 1 is that the humidification section 4, the germination section 5, and the drying section 6 are divided into three corresponding pipe boxes by four longitudinal screens (or perforated steel plates) 27. Two processing rooms. Humidification section 4 from left to right is the left humidification box 25a, the left humidification chamber 25d, the humidification middle tube box 25b, the right humidification chamber 25e, and the humidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com