Preparation method of tobacco spice

A technology for tobacco flavor and amino acid, applied in the directions of essential oils/spice, tobacco, application, etc., can solve the problems of difficult operation, complicated process, limited source of fenol, etc., to reduce side reactions, improve research value, and improve taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

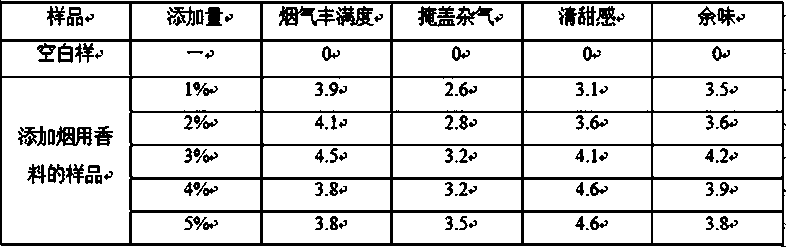

Examples

Embodiment 1

[0041] (1) Catalyzed reaction: put acetic acid and cinnamon essential oil into the reaction kettle according to the volume ratio of 3:1, add the amino acid functionalized ionic liquid catalyst of 6g / mL system and 20g / L Sodium alginate solution, stirred evenly; the reaction temperature was controlled at 45°C, and the reaction time was 1h;

[0042] The amino acid functionalized ionic liquid catalyst is [Gly] 3 PW 12 o 40 , the preparation method is: weigh 15mmol of glycine into a single-necked flask, add 15mL of deionized water to dissolve it; weigh 5mmol of phosphotungstic acid and add 10mL of deionized water to dissolve it; Stir under magnetic force for 24 hours; after the reaction is completed, the liquid in the single-necked flask is rotary evaporated to remove most of the water, and the remaining liquid is poured into a petri dish and placed in an electric heating constant temperature drying oven at 80°C for drying, and the obtained solid is [Gly] 3 PW 12 o 40 ;

[00...

Embodiment 2

[0050] (1) Catalyzed reaction: put acetic acid and cinnamon essential oil into the reaction kettle according to the volume ratio of 6:1, add 12g / mL system of amino acid functionalized ionic liquid catalyst and 3 times its volume mass concentration of 30g / L Sodium alginate solution, stirred evenly; the reaction temperature was controlled at 65°C, and the reaction time was 3h;

[0051] The amino acid functionalized ionic liquid catalyst is [Asp]H 2 PW 12 o 40 , the preparation method is: weigh 5mmol aspartic acid into a single-necked flask, add 15mL deionized water to dissolve it; weigh 5mmol phosphotungstic acid and add 10mL deionized water to dissolve it; add phosphotungstic acid liquid into a single-necked flask , magnetically stirred at 30°C for 24 hours; after the reaction was completed, the liquid in the single-necked flask was rotary evaporated to remove most of the water, and the remaining liquid was poured into a petri dish and placed in an electric heating constant t...

Embodiment 3

[0059] (1) Catalyzed reaction: put acetic acid and cinnamon essential oil into the reaction kettle according to the volume ratio of 4:1, add 10g / mL system of amino acid functionalized ionic liquid catalyst and 3 times its volume of 25g / L Sodium alginate solution, stirred evenly; the reaction temperature was controlled at 55°C, and the reaction time was 2h;

[0060] The sodium alginate solution.

[0061] Described amino acid functionalized ionic liquid catalyst is [Sar] 2 HPW 12 o 40 , the preparation method is: weigh 10mmol sarcosine into a single-necked flask, add 15mL deionized water to dissolve it; weigh 5mmol phosphotungstic acid and add 10mL deionized water to dissolve it; add phosphotungstic acid liquid into a single-necked flask, Stir magnetically at 30°C for 24 hours; after the reaction is completed, the liquid in the single-necked flask is rotary evaporated to remove most of the water, and the remaining liquid is poured into a petri dish and placed in an electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com