Preparation method of nano-gold modified titanium dioxide-carbon nanotube composite photocatalyst

A carbon nanotube composite and titanium dioxide technology, which is applied in the field of air purification, can solve the problems of consumption of organic solvents and template agents, difficulty in controlling the combination of three components, secondary hazards to the ecological environment, etc., and achieve excellent adsorption rate and excellent catalytic degradation effect , the effect of close interface relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a nano-gold modified titanium dioxide-carbon nanotube composite photocatalyst, comprising the following steps:

[0036] a) using an alcohol aqueous solution and a steady-state gas as a medium, and using a micro-nano bubble generator to obtain micro-nano bubble water;

[0037] b) mixing and dispersing the micronano bubble water, carbon nanotubes and titanium salt to obtain a dispersion;

[0038] c) mixing and hydrolyzing the dispersion with an aqueous ammonia solution to obtain a hydrolyzate;

[0039] d) After mixing the hydrolyzate with gold salt and micro-nano bubble water, sequentially carry out light reduction and heating reaction to obtain a reaction product;

[0040] e) heat-treating the reaction product to obtain Au-TiO 2 -CNTs composite photocatalyst.

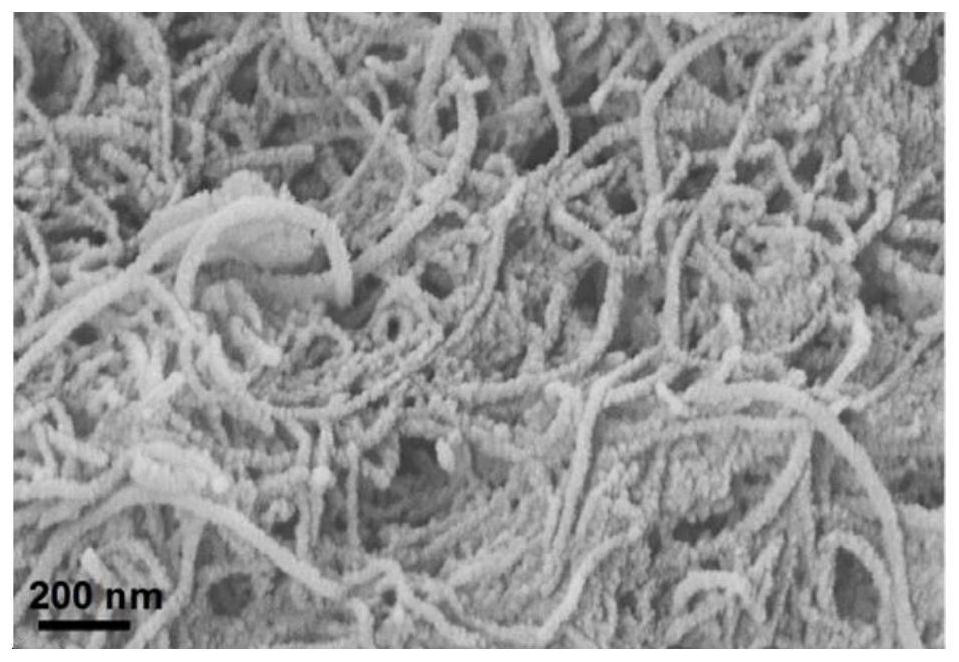

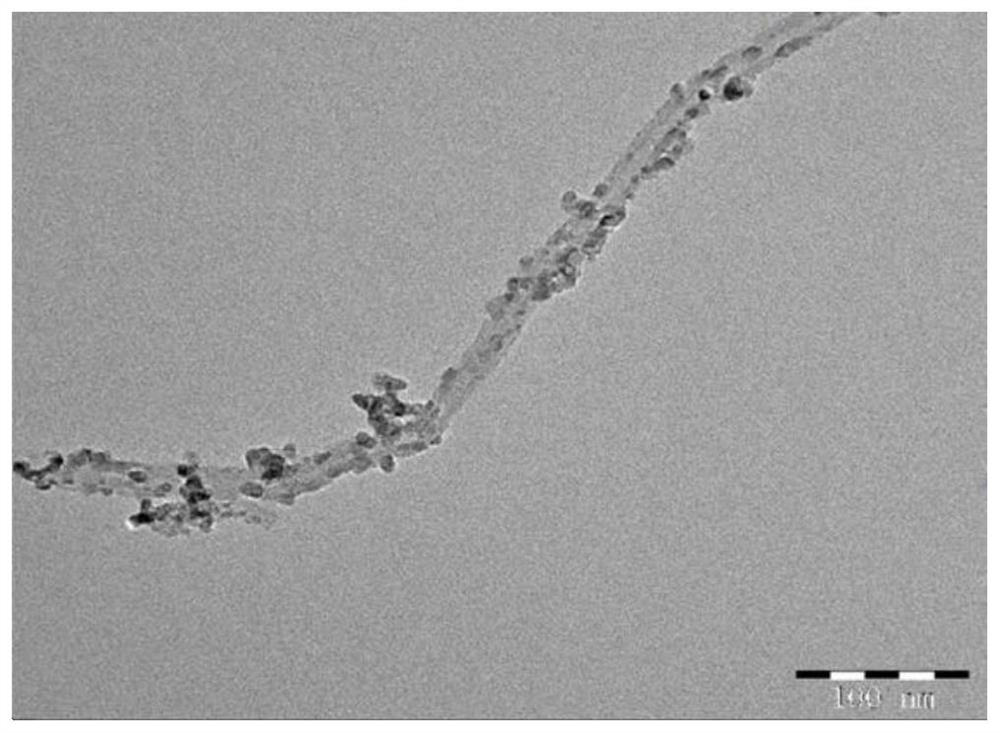

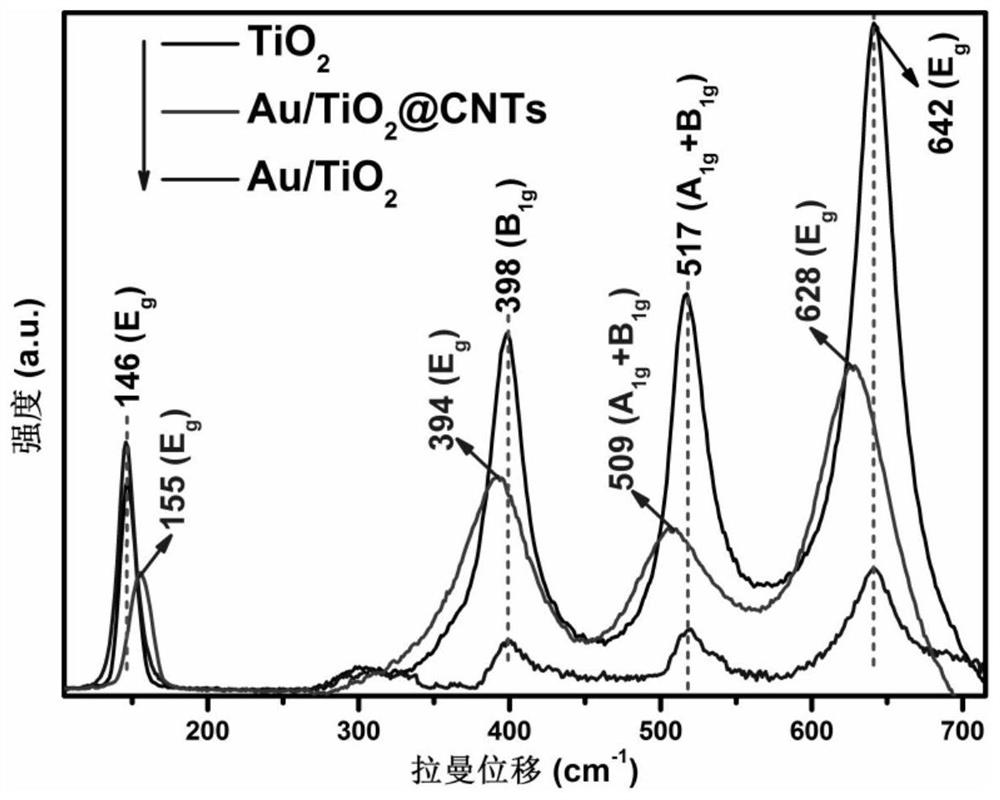

[0041] In the present invention, micro-nano bubble water is used as a soft template, combined with the above-mentioned specific treatment process, titanium salt, go...

Embodiment 1

[0067] 1.1 Sample preparation

[0068] Using 8L of 11% ethanol aqueous solution and air as the medium, using a micro-nano bubble generator equipped with a high-pressure micro-nano nozzle for processing, the working pressure is 0.40MPa, and the air intake rate is 1.5L / min. After treatment, we get Micro-nano bubble water. Take 80mL of micro-nano bubble water and put it in a 250mL conical flask, according to the mass ratio MWCNTs:TiO 2 =26% Add 83.2mg of MWCNTs and 4mmol TiCl to the above-mentioned micro-nano bubble water successively 4 , Place the Erlenmeyer flask in a sonicator for ultrasonic treatment for 15 minutes to obtain a uniform dispersion. A dilute ammonia solution with a concentration of 2.6% was gradually added dropwise to the above dispersion liquid until a sol state appeared, and then the hydrolysis reaction was continued for 13 hours at a room temperature of 30° C. to obtain a hydrolyzed product. Add 0.018 mmol HAuCl to the resulting hydrolyzate 4 10 mL of mic...

Embodiment 2

[0075] 1.1 Sample preparation

[0076] With 8L of 11% ethanol aqueous solution and air as the medium, the micro-nano bubble generator equipped with high-pressure micro-nano nozzles is used for processing, the working pressure is 0.40MPa, and the air intake rate is 3L / min. Nano sparkling water. Take 80mL of micro-nano bubble water and put it in a 250mL conical flask, according to the mass ratio MWCNTs:TiO 2 =26% Add 83.2mg of MWCNTs and 4mmol TiCl to the above-mentioned micro-nano bubble water successively 4 , Place the Erlenmeyer flask in a sonicator for ultrasonic treatment for 15 minutes to obtain a uniform dispersion. A dilute ammonia solution with a concentration of 2.6% was gradually added dropwise to the above dispersion liquid until a sol state appeared, and then the hydrolysis reaction was continued for 13 hours at a room temperature of 30° C. to obtain a hydrolyzed product. Add 0.018 mmol HAuCl to the resulting hydrolyzate 4 10 mL of micro-nano-bubble aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com