Hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, which is applied in the field of medium and low temperature coal tar full-fraction hydrocracking, can solve the problems of uneven heating of catalysts, poor adaptability of raw materials, and short operation cycle, so as to achieve long cycle, short service life, and good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

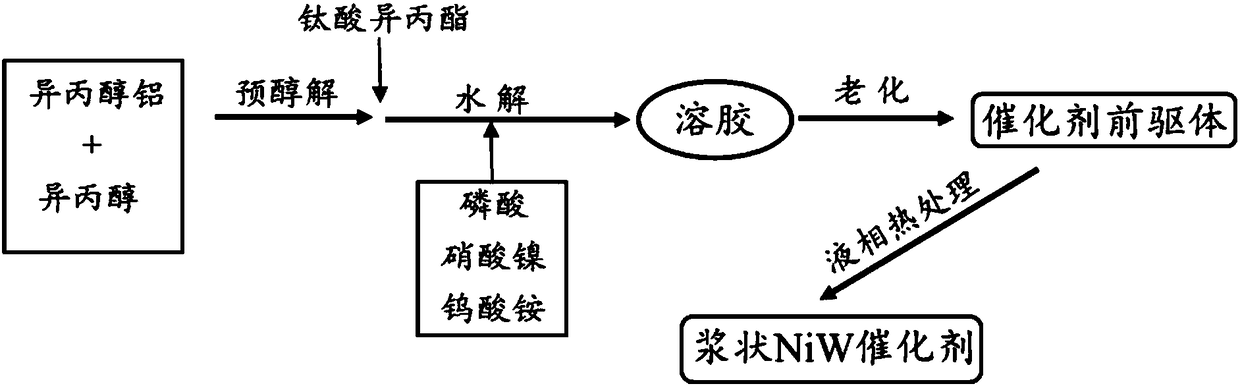

Method used

Image

Examples

example 1

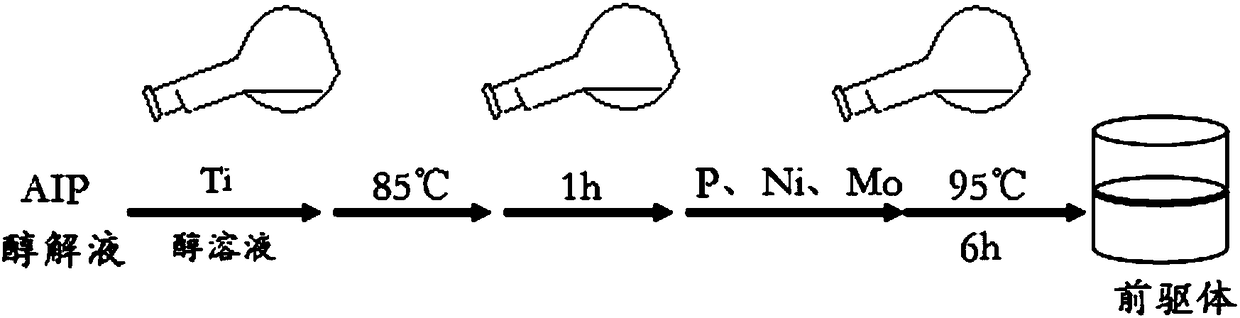

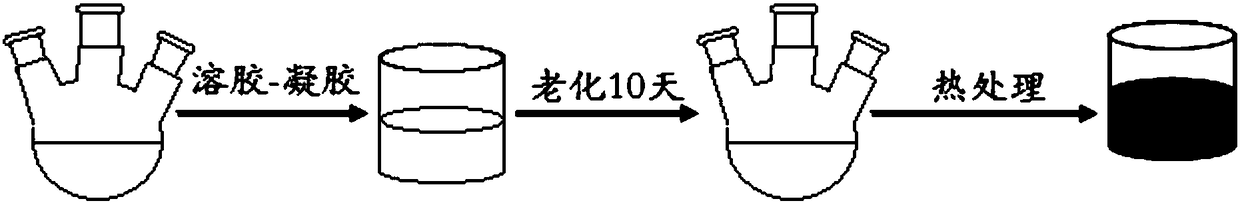

[0043] Weigh 39g of aluminum isopropoxide and add it to 90ml of isopropanol solution under vigorous stirring. When the water bath is heated to 82.5°C, reflux and stir for 4 hours, store at room temperature for 12 hours to form an alcoholysis solution; take titanium isopropoxide Add 15ml into an equal amount of isopropanol solution and stir evenly to form a mixed solution, then slowly drop the mixed solution into the alcoholysis solution; °C, when the temperature rises to 70 °C, use a peristaltic pump to add 250 ml of distilled water dropwise, and then count for 1 hour; at a water bath temperature of 85 °C, add phosphoric acid, Ni(NO 3 ) 2 ·6H 2 O in isopropanol, (NH 4 ) 10 W 12 o 41 ·xH 2 Aqueous solution of O, without addition of NH 4 F aqueous solution (wherein the feeding time interval is 1h, the phosphoric acid (calculated by P) content in weight percentage is 1wt%, the NiO content is 6.9wt%, WO 3 content is 24wt%), after the feeding is completed, the water bath is...

example 2

[0045] Weigh 39g of aluminum isopropoxide and add it to 90ml of isopropanol solution under vigorous stirring. When the water bath is heated to 82.5°C, reflux and stir for 4 hours, store at room temperature for 12 hours to form an alcoholysis solution; take titanium isopropoxide Add 15ml into an equal amount of isopropanol solution and stir evenly, then slowly drop the mixed solution into the alcoholysis solution; ℃, after adding 250ml of distilled water dropwise with a peristaltic pump, time it for 1h; 3 ) 2 ·6H 2 O in isopropanol, (NH 4 ) 10 W 12 o 41 ·xH 2 Aqueous solution of O, NH 4 The aqueous solution of F (wherein the feeding time interval is 1h, the phosphoric acid (calculated with P) content in weight percent is 1wt%, NiO content is 6.9wt%, WO 3 Content is 24wt%, NH 4 F (calculated as F) content is 1wt%); after the feeding is completed, the water bath is heated to 95 ° C for 6 hours, poured out and aged for 10 days to form the precursor of the hydrocracking ca...

example 3

[0047] Weigh 39g of aluminum isopropoxide and add it to 90ml of isopropanol solution under vigorous stirring. When the water bath is heated to 82.5°C, reflux and stir for 4 hours, store at room temperature for 12 hours to form an alcoholysis solution; take titanium isopropoxide Add 15ml into an equal amount of isopropanol solution and stir evenly, then slowly drop the mixed solution into the alcoholysis solution; At 70°C, use a peristaltic pump to add 250ml of distilled water dropwise, and time it for 1h; at a water bath temperature of 85°C, add phosphoric acid, Ni(NO 3 ) 2 ·6H 2 O in isopropanol, (NH 4 ) 10 W 12 o 41 ·xH 2 Aqueous solution of O, add NH 4 The aqueous solution of F (wherein the feeding time interval is 1h, the phosphoric acid (calculated with P) content in weight percent is 1wt%, NiO content is 6.9wt%, WO 3 Content is 24wt%, NH 4 F (calculated as F) content is 2wt%). After the feeding is completed, the water bath is heated to 95°C for 6 hours, poured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com