Filter type electrochemical reactor, water treatment device and water treatment method

An electrochemical and filtration technology, applied in chemical instruments and methods, filtration treatment, sterilization/microkinetic water/sewage treatment, etc., can solve the problems of low electrochemical oxidation efficiency, complicated electrode preparation, complicated operation steps, etc. Achieve the effects of short sewage purification time, enhanced mass transfer efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

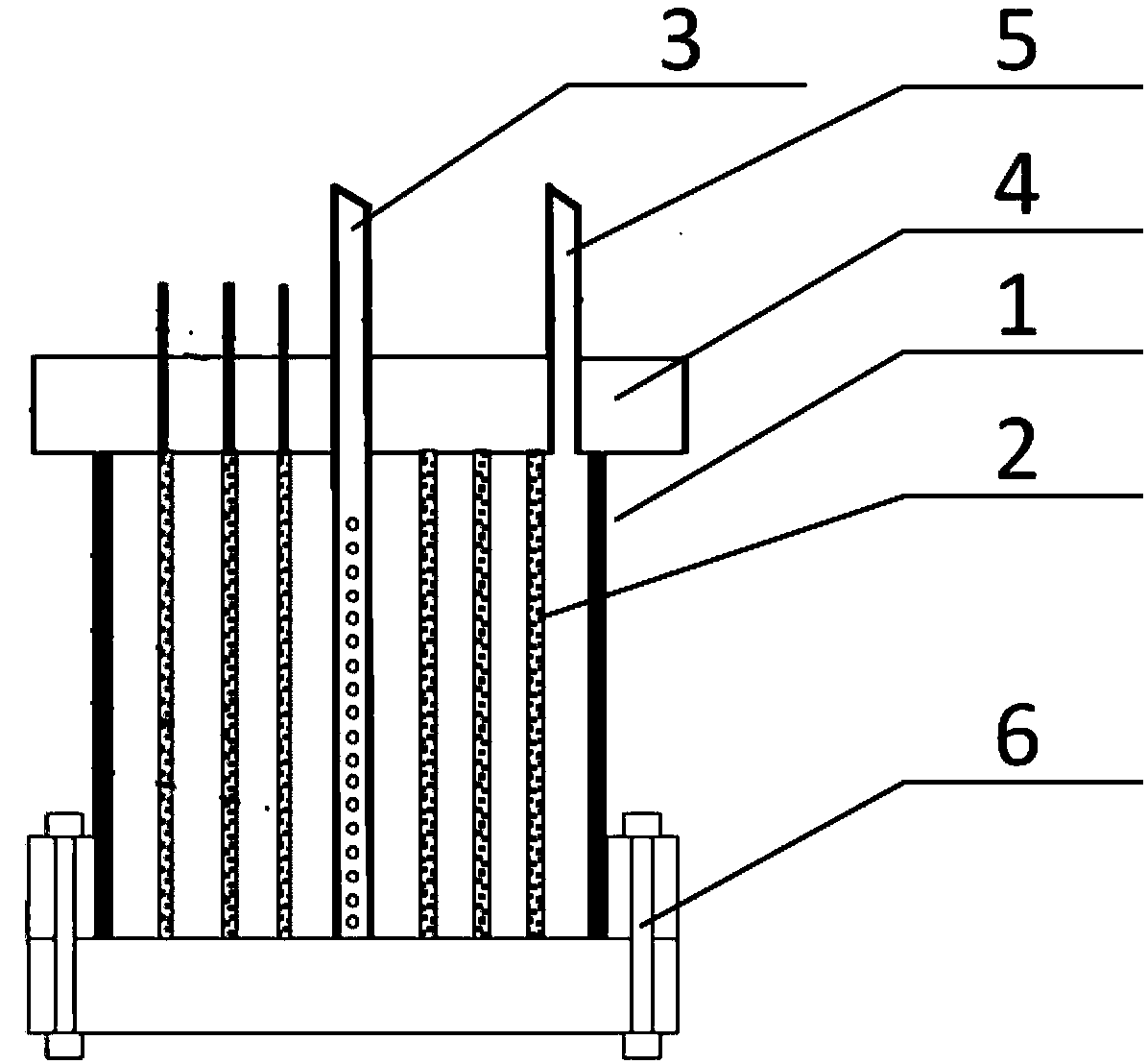

[0063] A filtered electrochemical reactor, such as figure 1 As shown, it includes a tubular reactor wall 1, a three-layer tubular porous electrode 2 sleeved inside the tubular reactor wall 1, a water distribution pipe 3 sleeved inside the tubular porous electrode 2, and the three-layer tubular porous electrode 2 forms a sleeve structure. From inside to outside, there are first tubular porous electrode 2, second tubular porous electrode 2, and third tubular porous electrode 2. The water distribution pipe 3 is set inside the first tubular porous electrode 2; Openings at both ends are packaged with plexiglass flanges 4 through bolts; the filter electrochemical reactor of this embodiment is provided with a water outlet 5, a cavity formed by the third tubular porous electrode 2, tubular reactor wall 1 and plexiglass flange 4 The body communicates with the water outlet 5;

[0064] The tubular reactor wall 1 is made of stainless steel;

[0065] A part of the water distribution pipe...

Embodiment 2

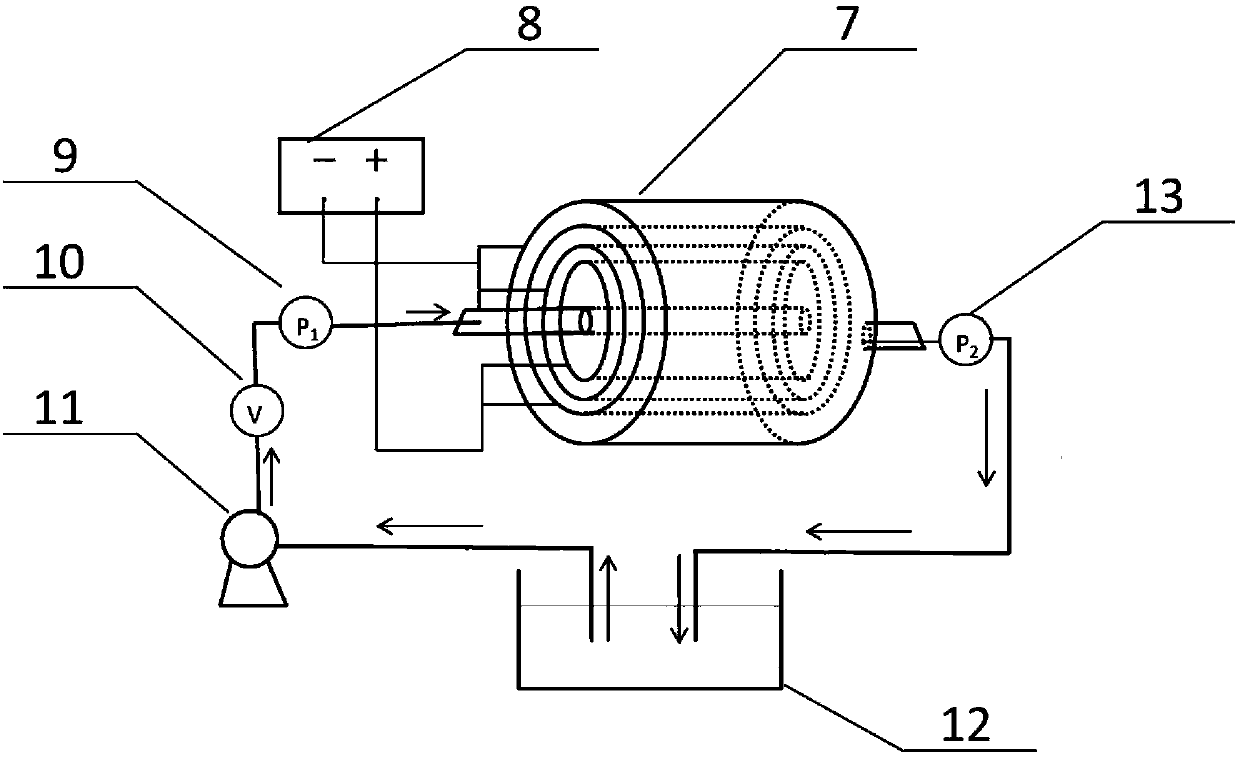

[0070] An electrochemical water treatment device, such as figure 2 Shown, comprise filter type electrochemical reactor 7 and DC power supply 8 of embodiment 1, also comprise water inlet tank 12, booster pump 11, flow meter 10, water inlet pressure gauge 9 and water outlet pressure gauge 13, water inlet tank 12, The booster pump 11, the flowmeter 10, the water inlet pressure gauge 9, and the water inlet of the filter electrochemical reactor 7 are connected through pipelines in turn, and the water outlet 5 of the filter electrochemical reactor 7, the water outlet pressure gauge 13, and the water inlet tank 12 connected by pipes in turn.

Embodiment 3

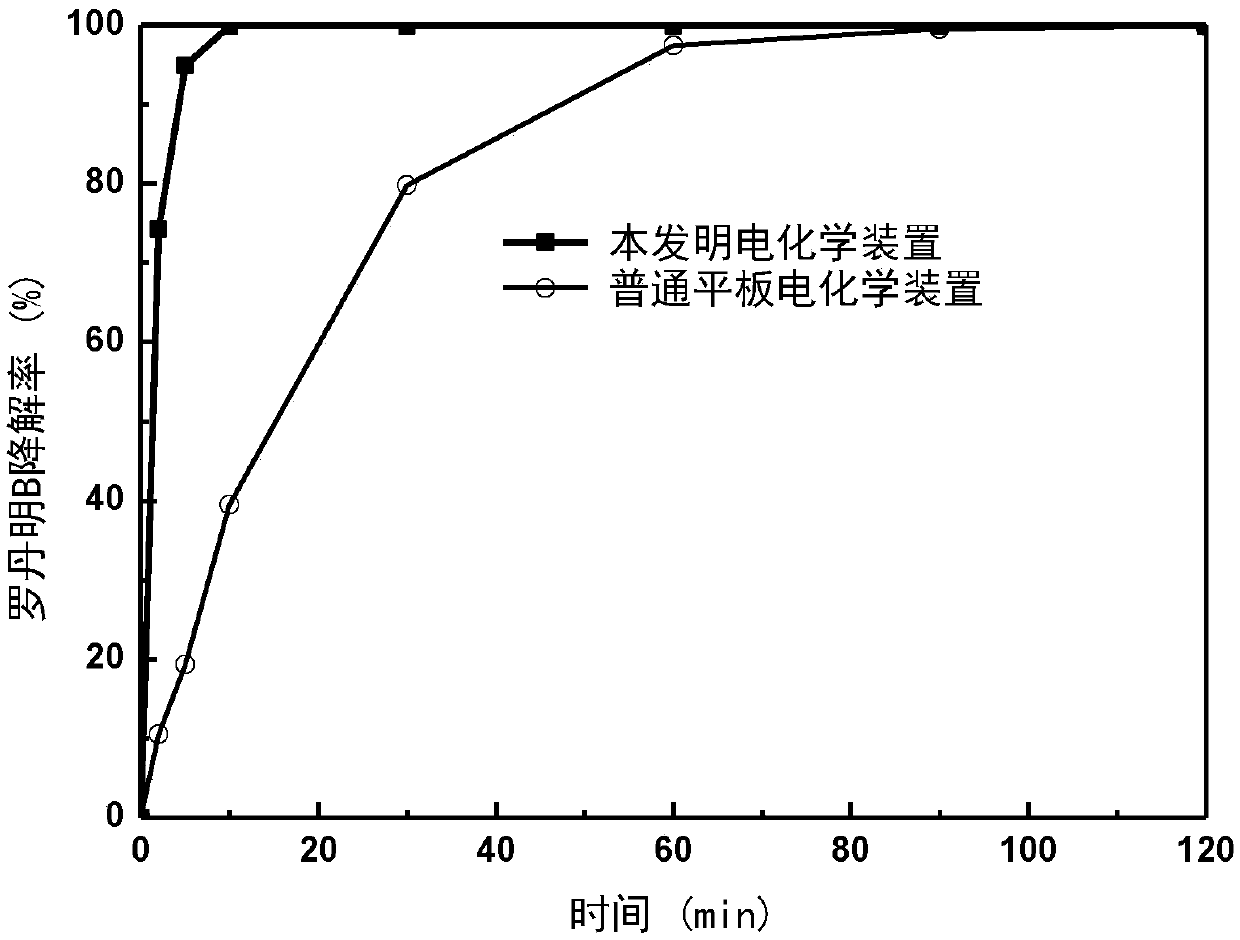

[0072] An electrochemical water treatment method, using the electrochemical water treatment device of embodiment 2 to treat printing and dyeing wastewater containing rhodamine B.

[0073] S1. Connect the negative pole of the DC power supply 8 to the cathode terminal, and the positive pole of the DC power supply 8 to the anode terminal;

[0074] S2. 2 L of printing and dyeing wastewater containing rhodamine B with an initial concentration of 200 mg / L is placed in the water inlet tank 12, and Na is added in the water inlet tank 12. 2 SO 4 The supporting electrolyte was made to have a concentration of 50 mM, the power was turned on, and the constant current mode was used to adjust the current density to 20 mA / cm 2 ;

[0075] S3. Turn on the booster pump 11, adjust the pressure difference between the inlet water and the outlet water of the filter electrochemical reactor 7 to be 1.0 MPa, and the printing and dyeing wastewater enters the filter electrochemical reactor 7 through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com