Method for treating washing wastewater of high-salt pickled vegetable by biology-physical chemistry combined technology

A combined technology, a technology for cleaning wastewater, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc. Tolerance, improved sludge life, improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

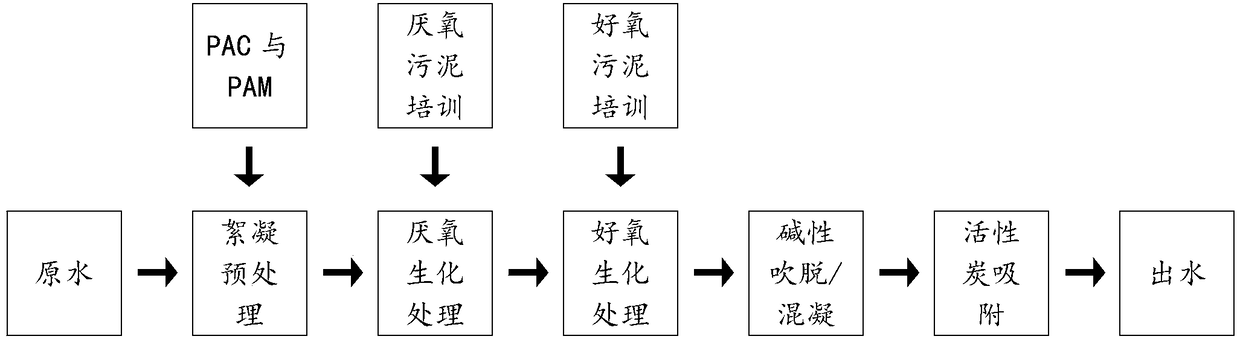

Method used

Image

Examples

Embodiment 1

[0032] The high-salt kimchi cleaning wastewater of Xinfan Kimchi Factory in Xindu District, Chengdu, the properties of the remaining sludge are as follows: COD is 3443mg / L, suspended solids SS is 885mg / L, ammonia nitrogen is 48.6mg / L, total phosphorus is 11.22mg / L, color The temperature is 115, the pH is 5, and the salt content is 12.3g / L.

[0033] Take 100ml of kimchi wastewater, control the dosage of PAC to 150mg / L in the flocculation pretreatment stage, the dosage of PAM to 25mg / L, pH6, temperature 30°C, 250r / min fast stirring for 2min, 90r / min slow stirring for 2min; the anaerobic stage control pH value to 7 , the residence time is 24h, the reaction temperature is 38°C; the aerobic phase controls the pH value to 7, the residence time is 4h, and the aeration intensity is 1000ml / (min L); the alkaline stripping control pH value is 9, and the aeration intensity is 0.6m 3 / h, the reaction time is 2.5h, 220mg / L ferric chloride is added 90s before the end of the alkaline strippin...

Embodiment 2

[0035] The high-salt kimchi cleaning wastewater of Xinfan Kimchi Factory in Xindu District, Chengdu, the properties of the remaining sludge are as follows: COD is 4963mg / L, suspended solids SS is 660mg / L, ammonia nitrogen is 53.6mg / L, total phosphorus is 14.4mg / L, color The temperature is 110, the pH is 4.5, and the salt content is 10.39g / L.

[0036] Take 100ml of kimchi wastewater, control the dosage of PAC to 150mg / L in the flocculation pretreatment stage, the dosage of PAM to 25mg / L, pH7, temperature at 25°C, stir at 250r / min for 2min, and stir at 90r / min for 2min; in the anaerobic stage, control the pH value to 8 , residence time 20h, reaction temperature 38°C; aerobic stage control pH value 7, residence time 6h, aeration intensity 1000ml / (min L); alkaline stripping control pH value 10, aeration intensity 0.6m 3 / h, the reaction time is 2.5h, 240mg / L ferric chloride is added 120s before the end of alkaline stripping, the reaction temperature is 35°C; the pH is controlled b...

Embodiment 3

[0038] The high-salt kimchi cleaning wastewater of Xinfan Kimchi Factory in Xindu District, Chengdu, the properties of the remaining sludge are as follows: COD is 3236mg / L, suspended solids SS is 1062mg / L, ammonia nitrogen is 32.4mg / L, total phosphorus is 13.05mg / L, color The temperature is 110, the pH is 5, and the salt content is 11.75g / L.

[0039] Take 100ml of kimchi wastewater, control the dosage of PAC to 150mg / L in the flocculation pretreatment stage, the dosage of PAM to 25mg / L, pH6, temperature 30°C, 250r / min fast stirring for 2min, 90r / min slow stirring for 2min; the anaerobic stage control pH value to 7 , the residence time is 24h, the reaction temperature is 38°C; the aerobic phase controls the pH value to 7, the residence time is 4h, and the aeration intensity is 1000ml / (min L); the alkaline stripping control pH value is 9, and the aeration intensity is 0.6m 3 / h, the reaction time is 2h, 200mg / L ferric chloride is added 150s before the end of alkaline stripping, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com