Diatom ooze composite material for interior decoration and preparation method thereof

A composite material and interior decoration technology, which is applied in the field of diatom mud composite materials for interior decoration and its preparation, can solve the problems of easy pulverization, mildew, and single function, and achieve good crack resistance, strong adsorption capacity, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

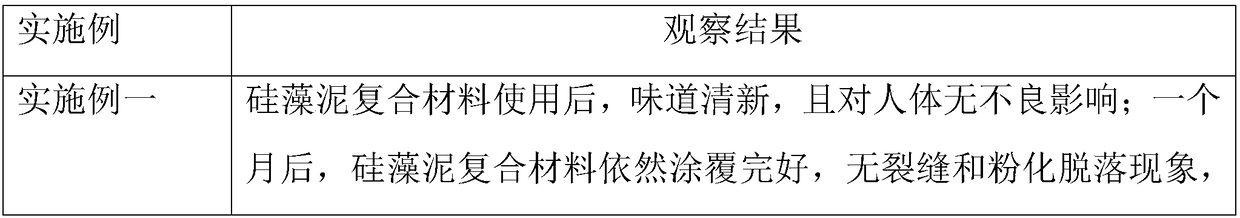

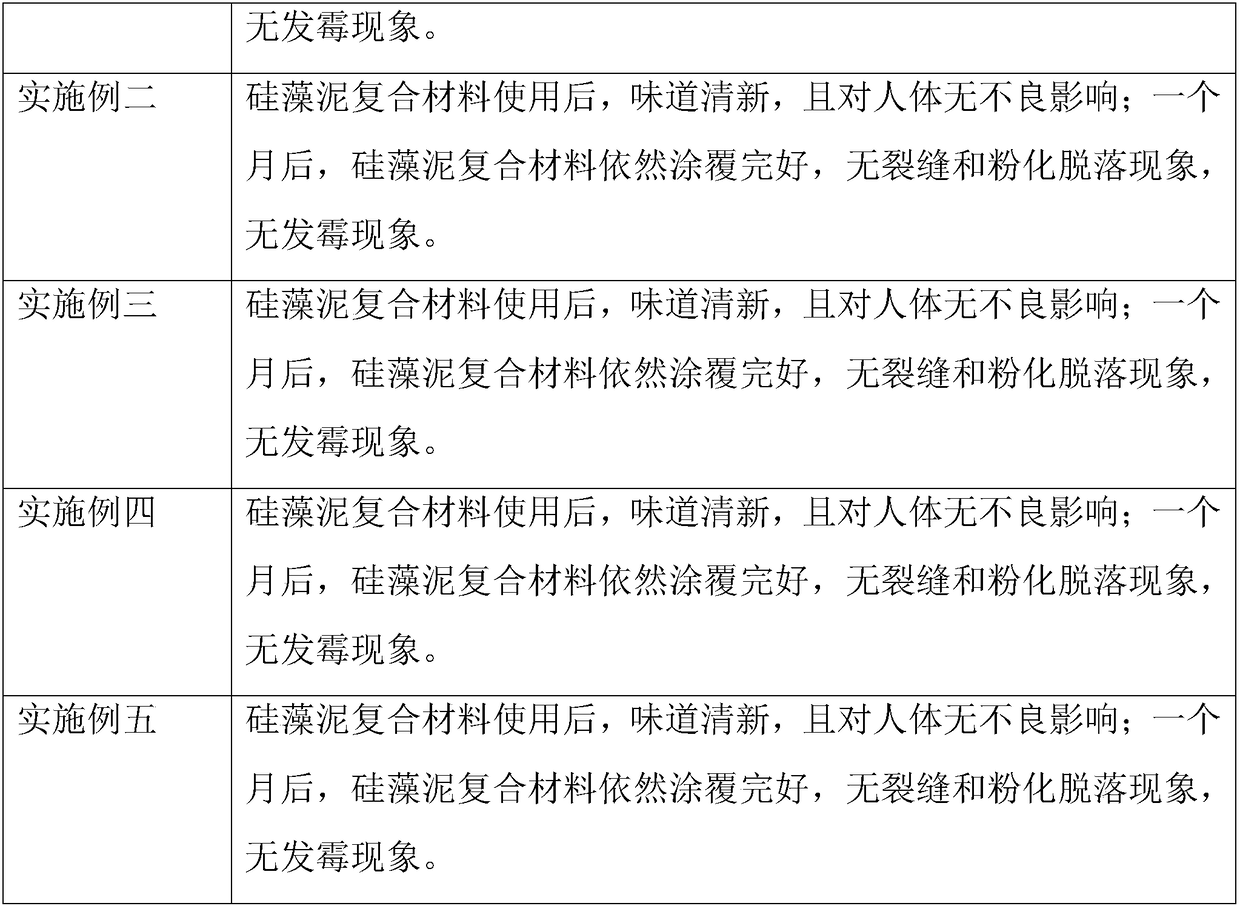

Examples

Embodiment 1

[0034] The diatom ooze composite material for interior decoration provided in this embodiment includes the following raw material components in parts by weight:

[0035] 45 parts of diatomite, 28 parts of ramie fiber, 17 parts of pine sawdust, 18 parts of sepiolite powder, 10 parts of zeolite powder, 20 parts of calcite powder, 15 parts of shell powder, 9 parts of attapulgite, 12 parts of bentonite, renewable 16 parts of dispersed latex powder, 10 parts of seaweed glue, 4.5 parts of hokuto stone powder, 0.5 parts of nano-titanium oxide, 4.5 parts of pine needle powder, 6 parts of mica powder, 2.5 parts of naringenin, 3.5 parts of thyme, 2 parts of tamarind shell, naked 4.5 parts of purple pearl, 3 parts of holly leaves, 1.5 parts of nepeta, and 3 parts of hydroxypropyl methylcellulose.

[0036] In this embodiment, the redispersible latex powder is vinyl acetate and ethylene copolymer powder; ethylene, vinyl chloride and vinyl lauricate ternary copolymer powder, vinyl acetate a...

Embodiment 2

[0043] The diatom ooze composite material for interior decoration provided in this embodiment includes the following raw material components in parts by weight:

[0044] 50 parts of diatomite, 28 parts of ramie fiber, 20 parts of pine sawdust, 18 parts of sepiolite powder, 12 parts of zeolite powder, 20 parts of calcite powder, 18 parts of shell powder, 9 parts of attapulgite, 15 parts of bentonite, recyclable 16 parts of dispersed latex powder, 12 parts of seaweed glue, 4.5 parts of hokuto stone powder, 1 part of nano-titanium oxide, 4.5 parts of pine needle powder, 8 parts of mica powder, 2.5 parts of naringenin, 4 parts of thyme, 2 parts of tamarind shell, naked 5.5 parts of purple pearl, 3 parts of holly leaves, 2 parts of nepeta, and 3 parts of hydroxypropyl methylcellulose.

[0045] In this embodiment, the redispersible latex powder is a ternary copolymerization rubber powder of ethylene, vinyl chloride and vinyl lauricate; vinyl acetate and ethylene copolymerization pow...

Embodiment 3

[0052] The diatom ooze composite material for interior decoration provided in this embodiment includes the following raw material components in parts by weight:

[0053] 50 parts of diatomite, 32 parts of ramie fiber, 20 parts of pine sawdust, 20 parts of sepiolite powder, 12 parts of zeolite powder, 22 parts of calcite powder, 18 parts of shell powder, 12 parts of attapulgite, 15 parts of bentonite, renewable 18 parts of dispersed latex powder, 12 parts of seaweed gel, 5 parts of hokuto stone powder, 1 part of nano-titanium oxide, 6 parts of pine needle powder, 8 parts of mica powder, 3.5 parts of naringenin, 4 parts of thyme, 3 parts of tamarind shell, naked 5.5 parts of purple pearl, 4.5 parts of holly leaves, 2 parts of nepeta, 3.5 parts of hydroxypropyl methylcellulose.

[0054] In this embodiment, the redispersible latex powder is vinyl acetate and ethylene copolymer powder; ethylene, vinyl chloride and vinyl lauricate ternary copolymer powder, vinyl acetate and higher f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com