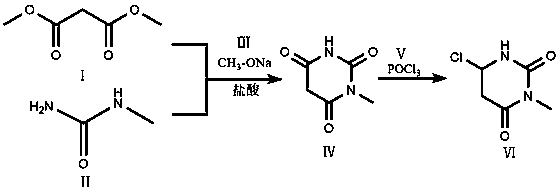

Preparation method of 6-chlorine-3-methyluracil

A technology of methyluracil and methylurea, which is applied in the field of biopharmaceuticals, can solve the problems of less than 60% overall yield, environmental pollution of large methyl iodide, and low yield of synthesis process, and achieve simple reaction process and safety Good, high yield and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of 1-methylbarbituric acid solid: Add 15g methylurea II and 11g sodium methoxide III to 500ml methanol solution, adjust the temperature to 50°C; keep the temperature, slowly add 24ml dimethyl malonate I dropwise for 2 hours; After the dropwise addition, the temperature was raised to 60°C for reflux reaction to generate 1-methylbarbituric acid IV; the reactant was cooled to 30°C, and the methanol was concentrated so that the total amount of methanol was concentrated to 60% of the total amount added initially, and 1-methylbarbituric acid IV was precipitated. Methyl barbituric acid solid IV crystals, filtered and dried;

[0042] Purification of 1-methylbarbituric acid crystals: control the temperature at 20°C, add hydrochloric acid to the dried 1-methylbarbituric acid solid IV crude product, the mass ratio of crystals to hydrochloric acid is 1:2.5; maintain the temperature Stir at 20°C, stir, centrifuge, and dry to obtain 1-methylbarbituric acid IV as a solid; ...

Embodiment 2

[0046] Preparation of 1-methylbarbituric acid solid: add 15g methylurea II and 11g sodium methoxide III to 500ml methanol solution, adjust the temperature to 40°C; keep the temperature, slowly add 24ml dimethyl malonate I dropwise for 1 hour; After the dropwise addition, the temperature was raised to 60°C for reflux reaction to generate 1-methylbarbituric acid IV; the reactant was cooled to 20°C, and the methanol was concentrated so that the total amount of methanol was concentrated to 80% of the total amount added initially, and 1-methylbarbituric acid IV was precipitated. Methyl barbituric acid solid IV crystals, filtered and dried;

[0047] Purification of 1-methylbarbituric acid crystals: control the temperature at 10°C, add hydrochloric acid to the dried 1-methylbarbituric acid solid IV crude product, the mass ratio of crystals to hydrochloric acid is 1:1.5; maintain the temperature Stir at 10°C, stir, centrifuge, and dry to obtain 1-methylbarbituric acid IV as a solid; t...

Embodiment 3

[0051] Preparation of 1-methylbarbituric acid solid: Add 15g methylurea II and 11g sodium methoxide III to 500ml methanol solution, adjust the temperature to 45°C; keep the temperature, slowly add 24ml dimethyl malonate I dropwise for 1.5h After the dropwise addition, the temperature was raised to 60°C for reflux reaction to generate 1-methyl barbituric acid IV; the reactant was cooled to 25°C, concentrated methanol, and the total amount of methanol was concentrated to 70% of the total amount added initially, and 1 -Methyl barbituric acid solid IV crystals, filtered and dried;

[0052] Purification of 1-methylbarbituric acid crystals: control the temperature at 15°C, add hydrochloric acid to the dried 1-methylbarbituric acid solid IV crude product, the mass ratio of crystals to hydrochloric acid is 1:2; maintain the temperature Stir at 15°C, stir, centrifuge, and dry to obtain 1-methylbarbituric acid IV as a solid; the yield is 90%, and the purity is 98%.

[0053] Preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com