Method for preparing carbon nanosphere with hierarchical pore high graphitization degree

A technology of carbon nanospheres and high graphite, applied in the field of preparation of carbon nanospheres, can solve the problems of poor electrical conductivity, waste of carbon spheres, and low degree of graphitization of carbon nanospheres, and achieve simple preparation methods, low processing temperatures, and simple procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

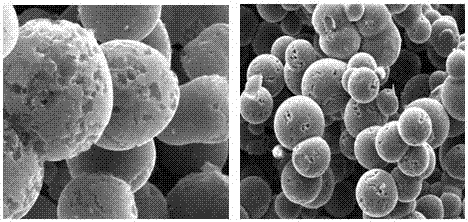

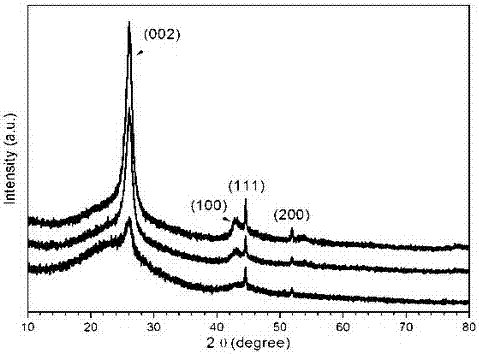

[0019] A method for preparing carbon nanospheres with hierarchical pores and high degree of graphitization, characterized in that the method steps are as follows:

[0020] (1) Using glucose and other biomass materials as raw materials, using nickel salt or cobalt salt as pore-forming agent and graphitization catalyst;

[0021] (2) Take 2g of glucose or starch, 4g of nickel nitrate or cobalt nitrate, 0.1g of anionic surfactant sodium dodecylbenzenesulfonate or sodium dodecyl sulfate, put in 30g of water, and stir ultrasonically until uniformly dispersed;

[0022] (3) Then put the above dispersion into a hydrothermal reaction kettle and react at 220°C for 8 hours;

[0023] (4) Repeatedly washing the amorphous carbon spheres after the hydrothermal reaction with alcohol and distilled water, and drying;

[0024] (5) Put the dried amorphous carbon material into a heating furnace, and heat-treat at 900°C for 3 hours in a nitrogen protective atmosphere;

[0025] (6) Wash the above s...

Embodiment 2

[0028] A method for preparing carbon nanospheres with hierarchical pores and high degree of graphitization, characterized in that the method steps are as follows:

[0029] (1) Using glucose and other biomass materials as raw materials, using nickel salt or cobalt salt as pore-forming agent and graphitization catalyst;

[0030] (2) Take 2g of glucose or starch, 6g of nickel nitrate or cobalt nitrate, 0.1g of anionic surfactant sodium dodecylbenzenesulfonate or sodium dodecylsulfate, put in 30g of water, and ultrasonically stir until uniformly dispersed;

[0031] (3) Then put the above dispersion into a hydrothermal reaction kettle and react at 220°C for 8 hours;

[0032] (4) Repeatedly washing the amorphous carbon spheres after the hydrothermal reaction with alcohol and distilled water, and drying;

[0033] (5) Put the dried amorphous carbon material into a heating furnace, and heat-treat at 900°C for 3 hours in a nitrogen protective atmosphere;

[0034] (6) Wash the above sa...

Embodiment 3

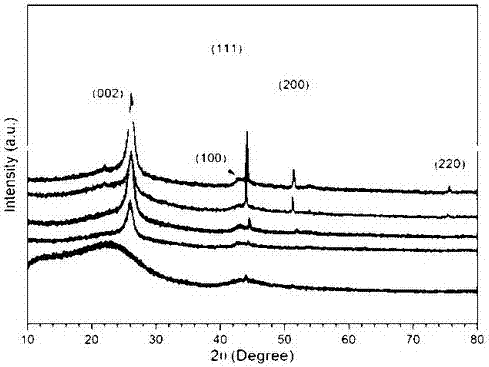

[0037] A method for preparing carbon nanospheres with hierarchical pores and high degree of graphitization, characterized in that the method steps are as follows:

[0038] (1) Using glucose and other biomass materials as raw materials, using nickel salt or cobalt salt as pore-forming agent and graphitization catalyst;

[0039] (2) Take 2g of glucose or starch, 8g of nickel nitrate or cobalt nitrate, 0.1g of anionic surfactant sodium dodecylbenzenesulfonate or sodium dodecylsulfate, put in 30g of water, and stir ultrasonically until uniformly dispersed;

[0040] (3) Then put the above dispersion into a hydrothermal reaction kettle and react at 220°C for 8 hours;

[0041] (4) Repeatedly washing the amorphous carbon spheres after the hydrothermal reaction with alcohol and distilled water, and drying;

[0042] (5) Put the dried amorphous carbon material into a heating furnace, and heat-treat at 900°C for 3 hours in a nitrogen protective atmosphere;

[0043] (6) Wash the above sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com