Diffusion dialysis membrane for recycling acid, as well as preparation method and application thereof

A diffusion dialysis and acid recovery technology, applied in the field of PVA-based anion exchange membrane and its preparation, can solve the problems of poor acid recovery performance, consumption of organic solvent, lack of chemical cross-linking, etc., and achieve excellent uniformity and strong controllability , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Diffusion dialysis membrane and preparation method thereof for acid recovery of the present invention can be summarized as follows:

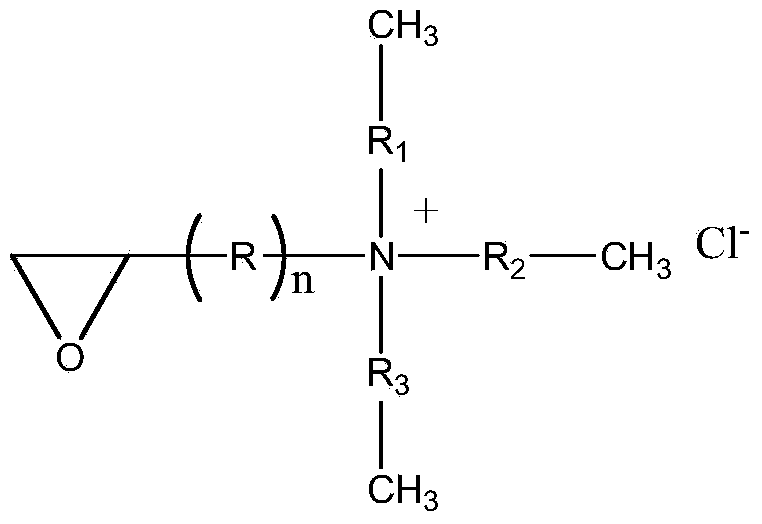

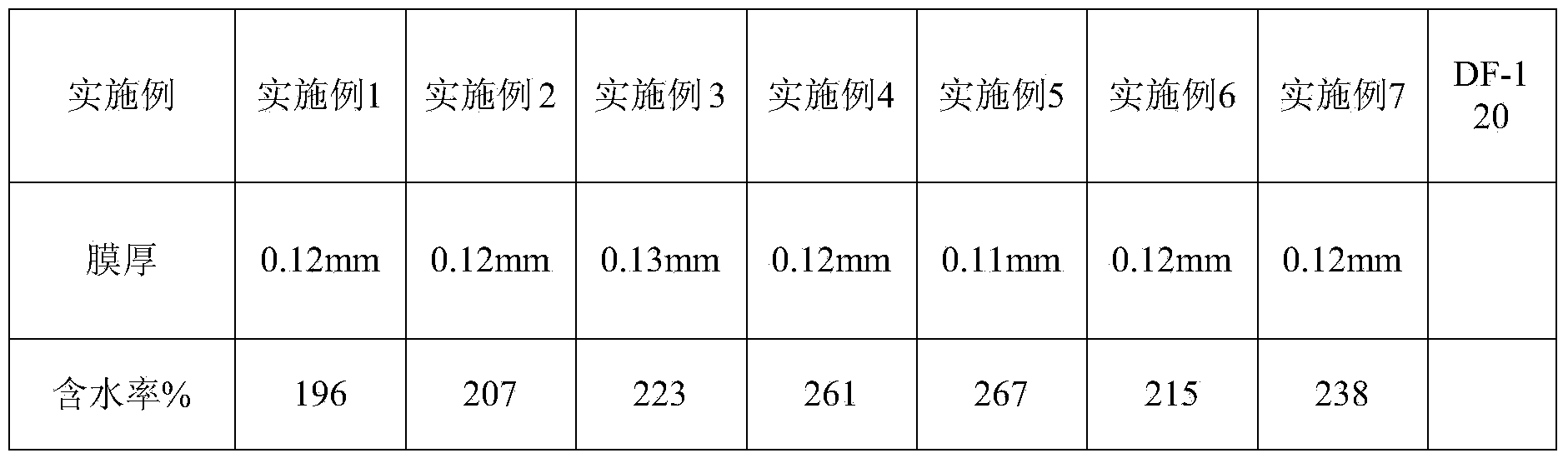

[0038] The diffusion dialysis membrane used for acid recovery consists of an organic phase and an inorganic phase. The organic phase is polyvinyl alcohol (purchased from Wanwei Group), and the inorganic phase is 2,3-epoxypropyltrimethylammonium chloride ( (purchased from Dongying Guofeng Fine Chemical Co., Ltd.) and aminoalkoxysilane (purchased from Nanjing Chengong Organic Silicon Materials Co., Ltd.). The water content of the ion exchange membrane is 196-267%, the ion exchange capacity is 0.58-1.15mmol / g, the acid dialysis coefficient is 0.018-0.021m / h, and the separation factor is 18.6-21.

[0039] The method for preparing the above-mentioned diffusion dialysis membrane adopts the following steps:

[0040] (1) Dissolution of PVA:

[0041] Polyvinyl alcohol (PVA) is dissolved in water to form a solution with a mass concentration of 5%...

Embodiment 2

[0057] (1) Dissolution of PVA:

[0058] Soak 5g of polyvinyl alcohol (molecular weight: 77000±2000) raw material in 95g of water for one day, then raise the temperature to about 102°C at a heating rate of 5-10°C / h under stirring conditions, and keep it at 102°C for 2.5h , to obtain a uniform and transparent solution, which is cooled to about 60° C. for later use, and the mass concentration of the solution is 5%.

[0059] (2) PVA grafted 2,3-epoxypropyltrimethylammonium chloride:

[0060] Add 1.5 g of 2,3-epoxypropyltrimethylammonium chloride to the solution prepared above, adjust the pH value to 11-12 with KOH, and control the temperature range of the solution to 85° C.; magnetic stirring, and react for 6 hours.

[0061] (3) Preparation of membrane solution:

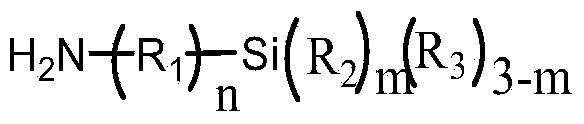

[0062] Graft 2,3-epoxypropyltrimethylammonium chloride to the PVA prepared in step (2) in proportion

[0063] 1 g of 3-aminopropyltrimethoxysilane was added to the solution, and after magnetic stirring, the temperatur...

Embodiment 3

[0074] (1) Dissolution of PVA:

[0075] Soak 5g of polyvinyl alcohol (molecular weight: 77000±2000) raw material in 95g of water for one day, then raise the temperature to about 102°C at a heating rate of 5-10°C / h under stirring conditions, and keep it at 102°C for 2.5h , to obtain a uniform and transparent solution, which is cooled to about 60° C. for later use, and the mass concentration of the solution is 5%.

[0076] (2) PVA grafted 2,3-epoxypropyltrimethylammonium chloride:

[0077] Add 2.5 g of 2,3-epoxypropyltrimethylammonium chloride to the solution prepared above, adjust the pH value to 11-12 with ammonia water, and control the temperature range of the solution to 90° C.; magnetic stirring, and react for 5 hours.

[0078] (3) Preparation of membrane solution:

[0079] Add 1 g of 3-aminopropyltrimethoxysilane to the PVA grafted 2,3-epoxypropyltrimethylammonium chloride solution prepared in step (2) in proportion, after magnetic stirring, heat up to 60°C, Stirring wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com