Preparing method for producing bright structure color material through strong electromagnetic resonance

An electromagnetic resonance and structural color technology, applied in the field of optics, can solve problems such as inability to achieve luminous enhancement or antenna application effects, weak electromagnetic resonance, etc., and achieve the effect of increased peak intensity and great practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

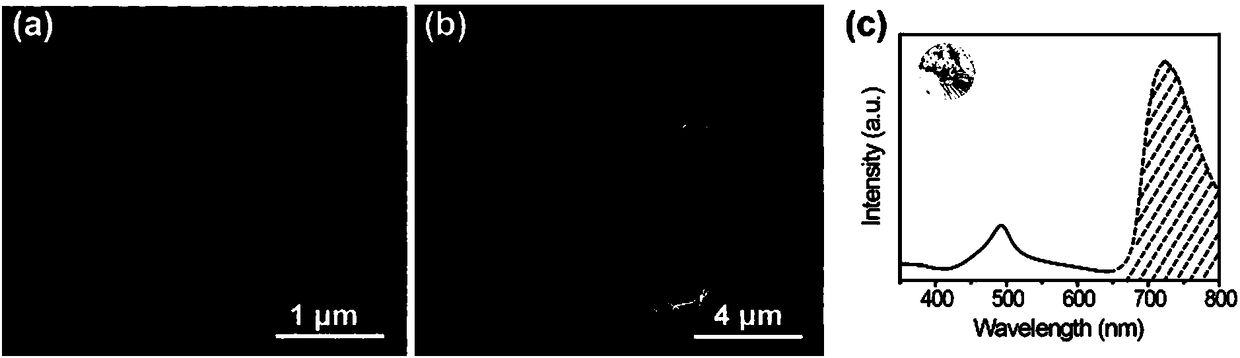

Embodiment 1

[0030] Based on the three-dimensional ordered structure of CdS dielectric microspheres to generate strong electromagnetic resonance and obtain the preparation process of cyan structural color, the specific preparation method is as follows:

[0031] 1. Preparation of Matrix Materials

[0032] Take a clean glass slide with a size of 2.5cm*2.5cm, mix the PDMS prepolymer and curing agent with a mass ratio of 10:1 with a homogenizer, and then spin-coat it on one side of the glass slide, set the speed of the homogenizer 8000rmp, time 40s. Transfer it to a heating plate, set the temperature at 90° C., and cure for 3 hours.

[0033] 2. Preparation of CdS dispersion

[0034] 0.2 g of CdS microspheres with particle diameters of 265 nm were weighed to form an aqueous dispersion with a mass fraction of 8 wt%, and ultrasonicated for 40 min.

[0035] 3. Preparation of three-dimensional ordered structure of CdS

[0036] A three-dimensional ordered structure with CdS microspheres as build...

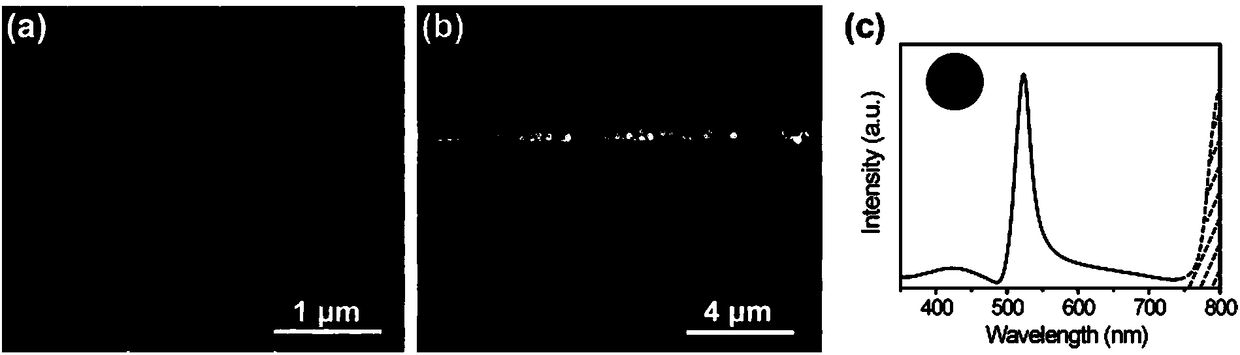

Embodiment 2

[0038] Based on the highly ordered three-dimensional structure of CdS dielectric microspheres, the strong electromagnetic resonance phenomenon and the preparation process of green structural color are obtained. The specific preparation method is as follows:

[0039] 1. Preparation of Matrix Materials

[0040] Take a clean glass slide with a size of 2.5cm*2.5cm, wash it three times with deionized water and ethanol, and dry it for use.

[0041] 2. Preparation of CdS dispersion

[0042] 0.1 g of CdS microspheres with particle diameters of 310 nm were weighed, prepared into an ethanol dispersion with a mass fraction of 3 wt%, and ultrasonicated for 30 min.

[0043] 3. Preparation of three-dimensional ordered structure of CdS

[0044] A three-dimensional ordered structure with CdS microspheres as building units was obtained by vertical deposition. The specific steps are as follows: vertically immerse the glass slide in the ethanol dispersion of CdS microspheres, vacuumize, keep th...

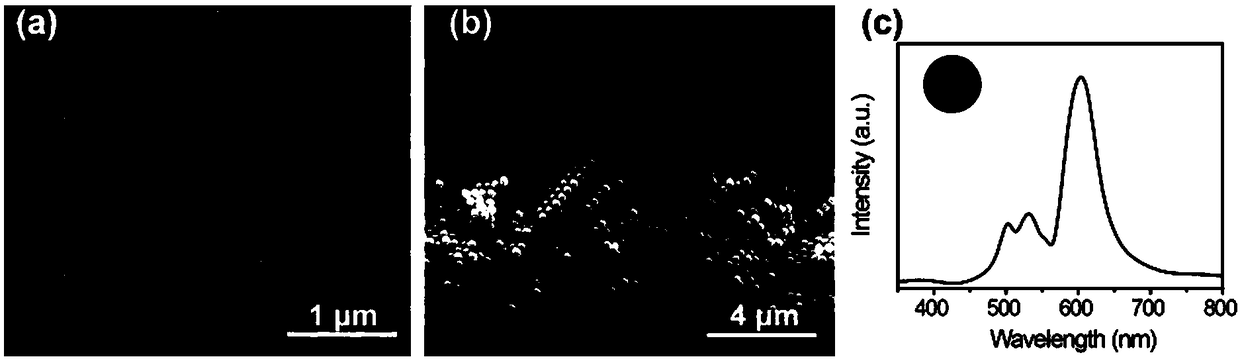

Embodiment 3

[0046] Based on the three-dimensional ordered structure of CdS dielectric microspheres, the electromagnetic resonance phenomenon is produced and the orange-red structural color is obtained. The specific preparation method is as follows:

[0047] 1. Preparation of Matrix Materials

[0048] Cut out a waterproof photo paper with a size of 2cm*2cm. The substrate is a flexible substrate, and the substrate has undergone a certain waterproof treatment and has a certain degree of hydrophobicity. Its contact angle is about 63°.

[0049] 2. Preparation of CdS dispersion

[0050] 0.3 g of CdS microspheres with a particle diameter of 375 nm were weighed to form an aqueous dispersion with a mass fraction of 15 wt%, and ultrasonicated for 20 min.

[0051] 3. Preparation of three-dimensional ordered structure of CdS

[0052] A three-dimensional ordered structure with CdS microspheres as building units was obtained by horizontal evaporation-induced assembly. The specific steps are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com