Preparing method for composite probiotic product

A technology of compound probiotics and probiotics, applied in microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve problems such as inactivation, and achieve the effect of storage resistance and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

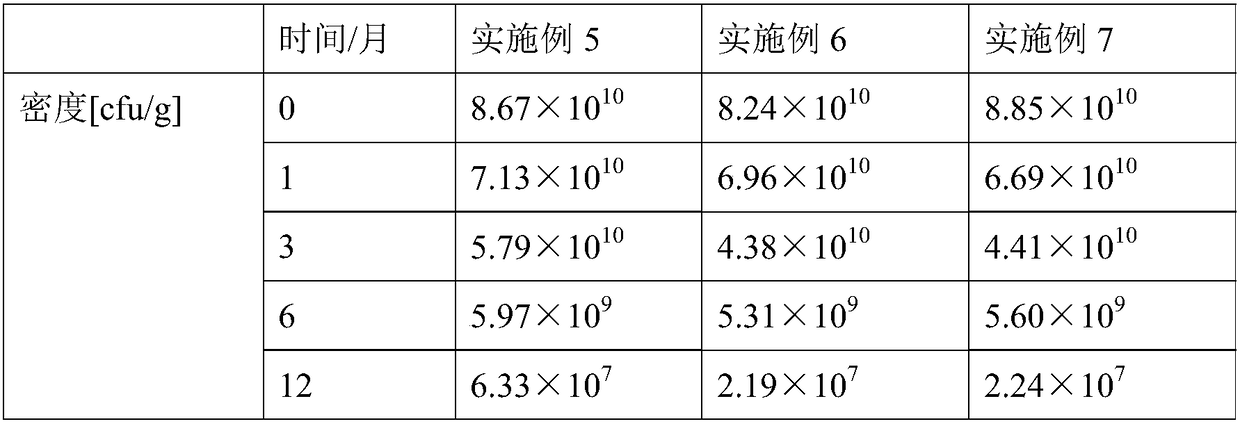

Examples

preparation example Construction

[0023] The preparation method of the composite probiotic product provided by the invention, the method comprises the following steps:

[0024] 1) Preparation of culture medium: mixing whey powder, tryptone casein, peptone, yeast extract, inorganic salts and amino acids to prepare a liquid culture medium;

[0025] 2) Activation: Inoculate the probiotics into the liquid medium and culture them at 35-45°C to obtain an activated strain solution; the probiotics are two or more of Bifidobacterium adolescentis, Streptococcus thermophilus and Lactobacillus fermentum;

[0026] 3) Embedding: add sterilized 1-4wt% sodium alginate solution to the activated strain solution, and add dropwise to sterilized 0.05-0.2mol / L CaCl 2 In the solution, after solidification, filter to obtain embedded carrier particles;

[0027] The embedding treatment can effectively cultivate and amplify active bacteria in a directional way between activation and expansion culture, which increases the controllabilit...

Embodiment 1

[0032] Embodiment 1: the preparation of liquid culture medium

[0033] Take 5g whey powder, 5g tryptone casein, 3g peptone, 8g yeast extract, 0.1g CaCl 2 2H 2 O, 0.3g MgSO 4 ·7H 2 O, 0.8g K 2 HPO 4 , 0.8g KH 2 PO 4 , 5g NaHCO 3 , 1g NaCl, 0.3g cysteine hydrochloride·H 2 After adding water and mixing evenly, adjust the pH to 7.0, add water to make the volume to 1L, and obtain a liquid medium.

Embodiment 2

[0035] A suspension of compound probiotics, made through the following steps:

[0036] 1) Activation: take 0.1 mL each of Bifidobacterium adolescentis and Lactobacillus fermentum, inoculate the inoculum into 20 mL of liquid medium, and culture at 37.5°C for 18 hours to obtain an activated strain solution;

[0037] 2) Embedding: Add 20 mL of sterilized 2.5 wt% sodium alginate solution to the activated strain solution dropwise to a sufficient amount of sterilized 0.1 mol / L CaCl 2 solution, until the amount of precipitation no longer increases, let it stand for 45 minutes, and filter to obtain embedded carrier particles;

[0038] 3) Expansion of growth: add CaCO to the liquid medium in an amount of 2.5g / 100mL 3 , inoculating the carrier particles into the liquid culture medium in an amount of 12 g / mL to obtain probiotic particles, and washing with sterile water;

[0039] 4) Suspension: Add probiotic granules to 20 mL of 2.5 wt% sodium citrate solution, and place at 37.5° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com