High-capacity long-service-life AB<4.5> type hydrogen storage alloy and preparation method thereof

An AB4.5, hydrogen storage alloy technology, applied in electrical components, circuits, battery electrodes, etc., can solve problems such as difficult to lose metal hydrides, low discharge capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] An AB with both high capacity and long life 4.5 A method for preparing a type hydrogen storage alloy, comprising the steps of:

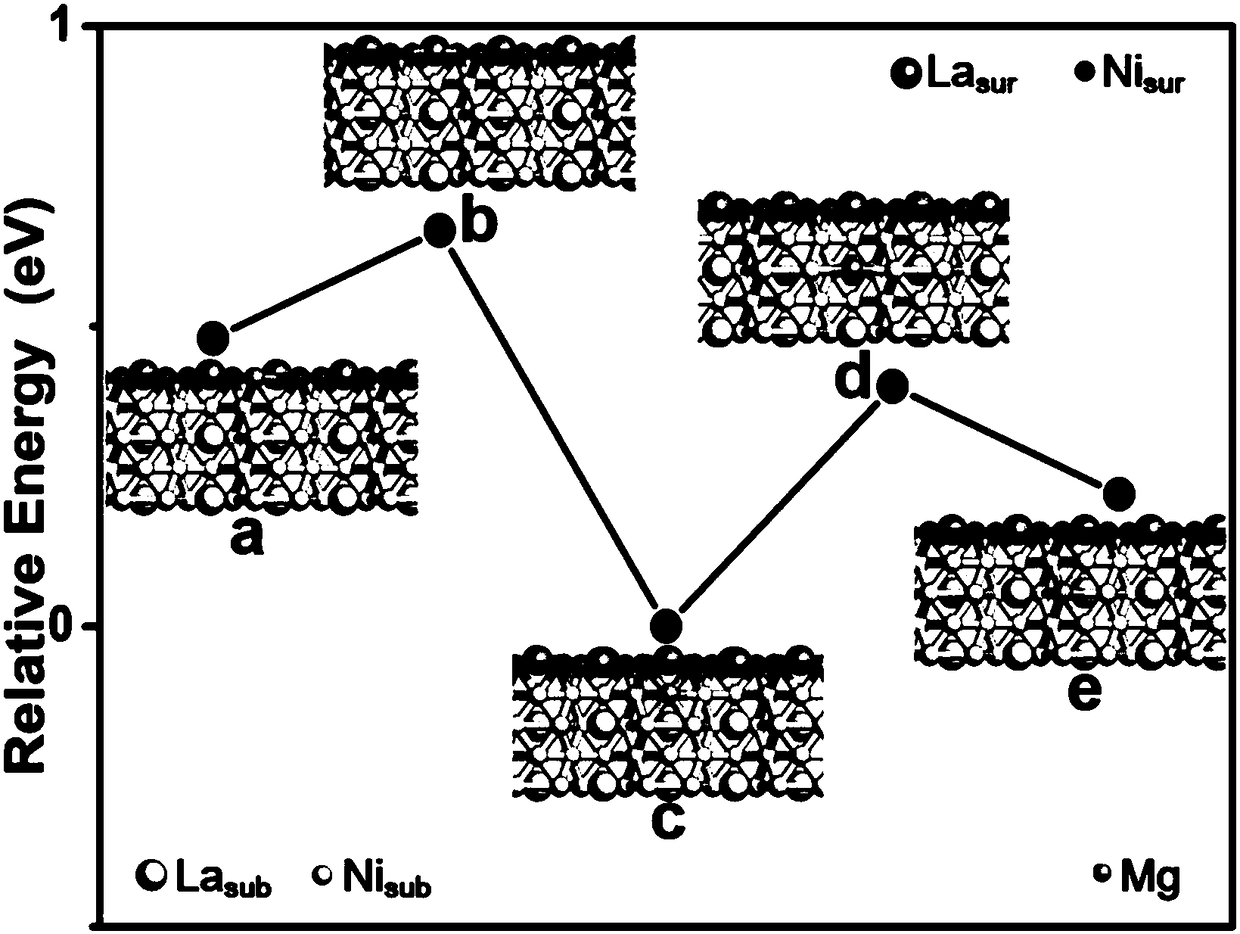

[0050] a. DFT simulation calculations are performed using Vienna ab initio Simulation Package (VASP) software; the exchange-correlation function is a PBE functional based on generalized gradient approximation; in order to consider the van der Waals interaction between atoms, DFT-D3 dispersion based on Becke-Jonson damping is used ;Aiming at the interaction between ions and electrons, the plane wave projection method is used to describe;

[0051] b. The cut-off energy of the plane wave basis set is 400eV, and the convergence criterion of the electronic self-consistent field iteration is 10 -5 eV, the convergence criterion for atomic geometry optimization is

[0052] c. According to the Monkhorst-Pack method, the Brillouin zone is divided into 3×3×1 K-point grids; in order to speed up the convergence of the electronic self-consistent field i...

Embodiment

[0057] The preparation process and steps in this embodiment are as follows:

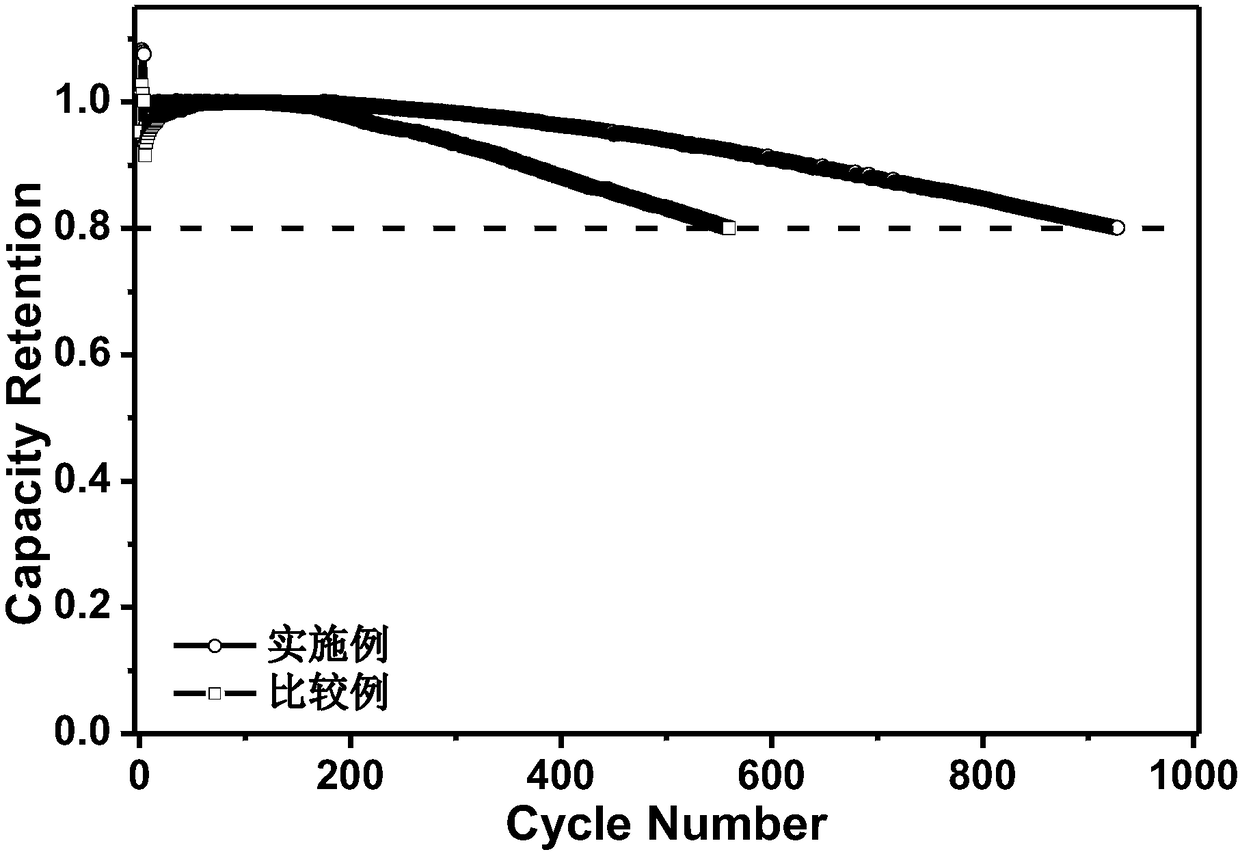

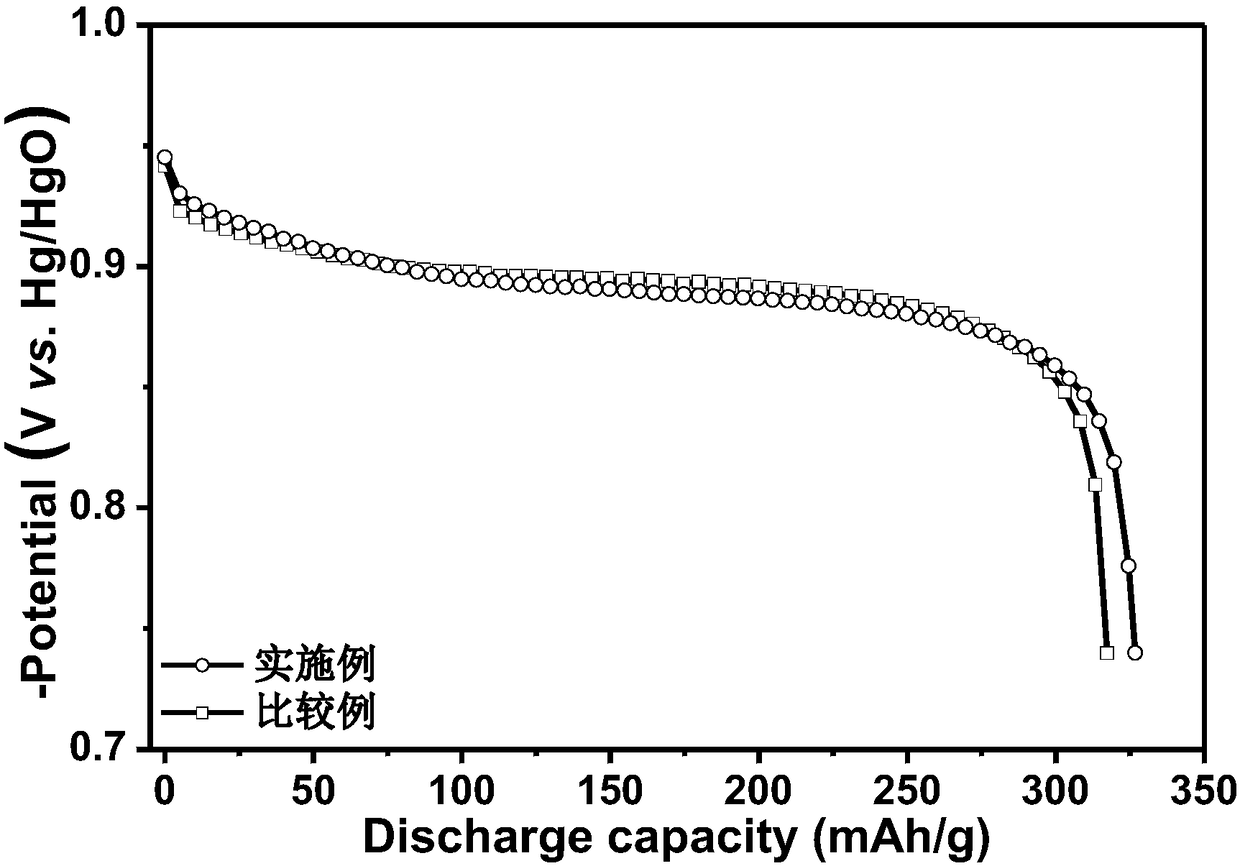

[0058] (1) Using the DFT method to construct LaNi when Mg atoms replace different Ni atom positions 5 Alloy configuration, set calculation parameters, calculate energy and energy changes of different systems;

[0059] (2) According to La 0.62 Mg 0.08 Ce 0.2 Y 0.1 Ni 3.25 co 0.75 mn 0.2 Al 0.3 The chemical ratio is used for batching, and lanthanum, cerium, yttrium, magnesium, nickel, cobalt, manganese, and aluminum with a purity ≥ 99.5 are smelted by vacuum induction melting in a high-purity argon atmosphere to obtain ingots. The ingot is then kept at 1000°C for 5 hours under an argon protective atmosphere, and then quickly cooled with the furnace fan to ensure that the furnace temperature drops below 500°C within 5 minutes. Finally, the annealed alloy is powdered under the protection of inert gas or low-temperature liquid nitrogen, and the alloy powder with an average particle size of 45-55 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com