Bi-metal phosphide electrocatalyst as well as preparation method thereof and application thereof

A phosphide electric and bimetallic technology, applied in metal material coating process, electrode, electrolysis process, etc., to achieve the effect of lowering reaction barrier, improving electron transport and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

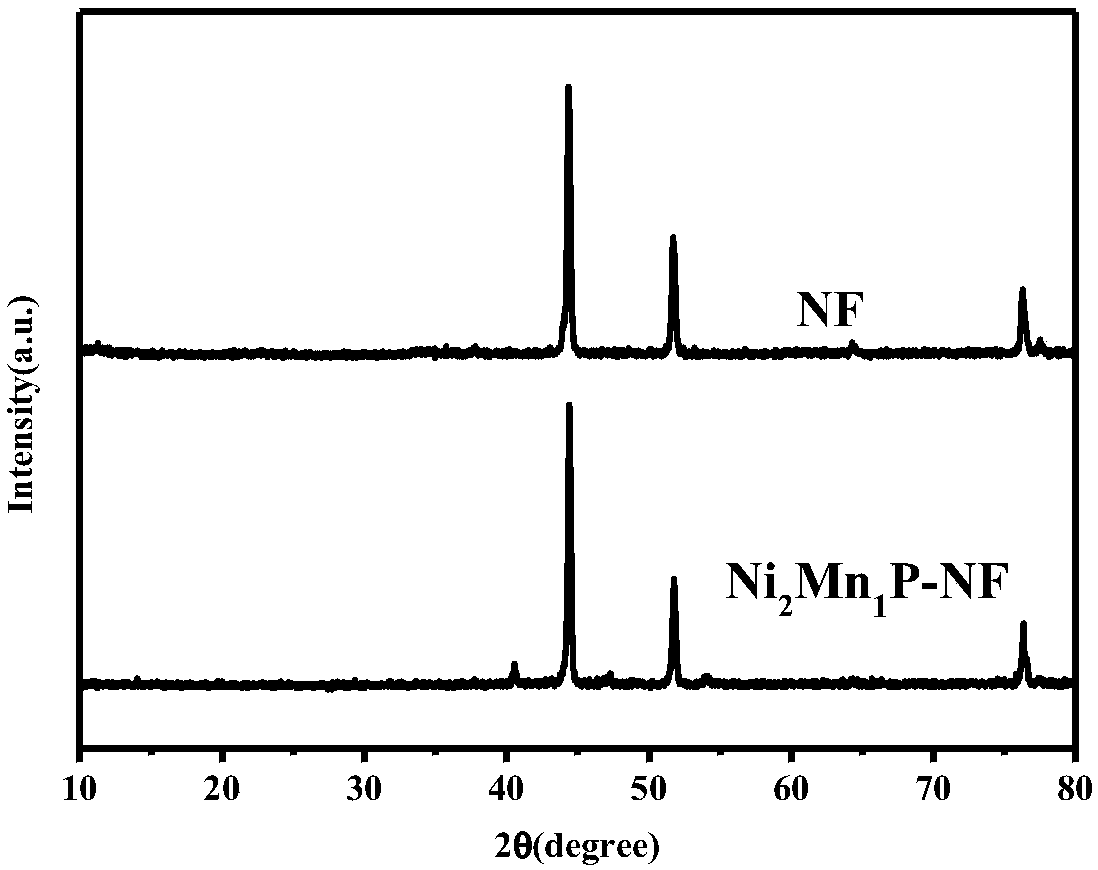

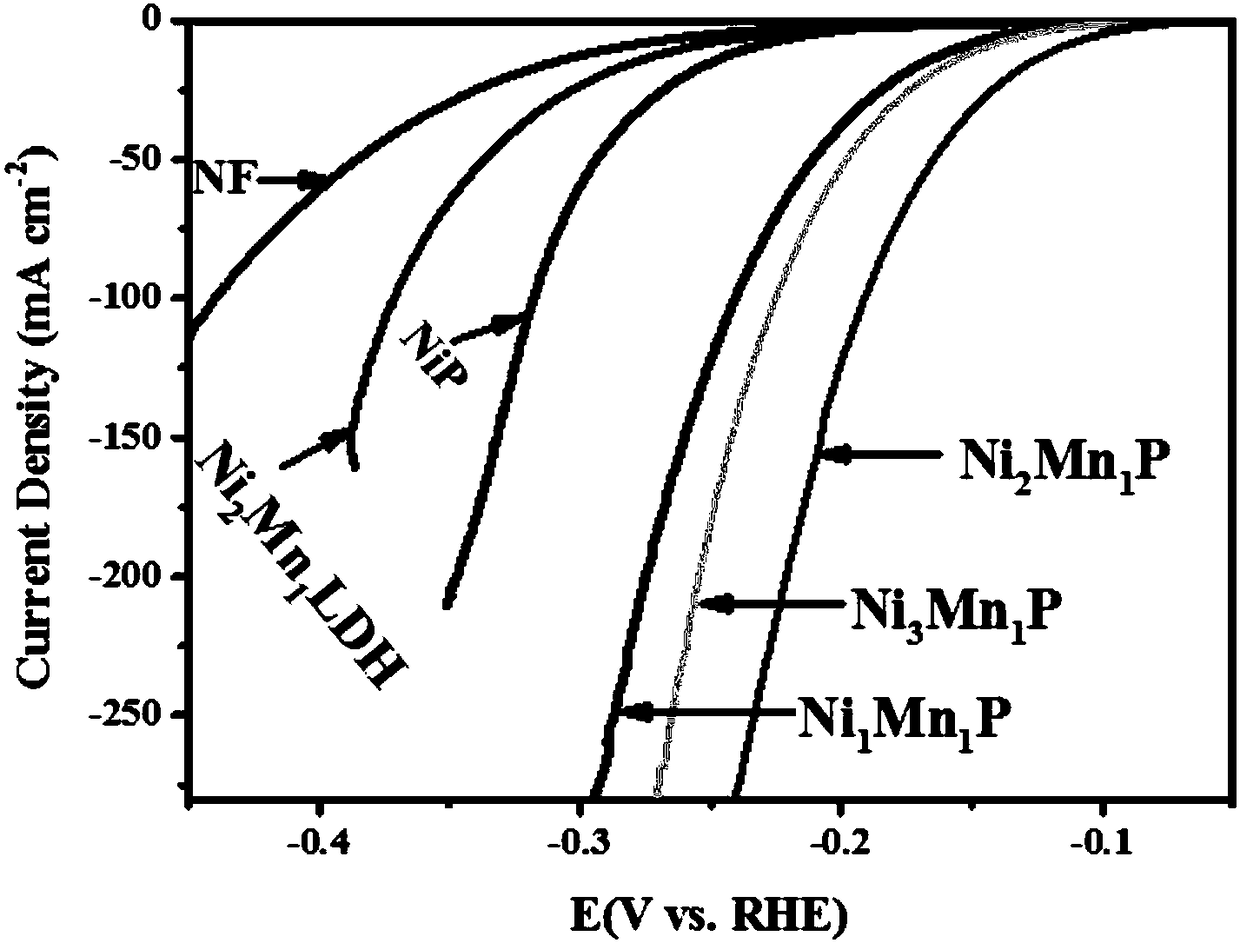

[0031] Nickel-manganese-phosphorus bimetallic phosphide (Ni 2 Mn 1 P-NF) preparation:

[0032] The nickel foam was ultrasonically cleaned with acetone, hydrochloric acid with a concentration of 3M, ethanol and deionized water for 30 minutes, and then dried at 60°C.

[0033] Weigh 0.118g NiCl 2 ·6H 2 O, and 0.0495g MnCl 2 ·4H 2 O, add 80mL deionized water to get precursor solution A (Ni:Mn=2:1); weigh out 0.0872g NaCl, 0.6308g HMT, 56.6μL H 2 O 2 (30w%) into solution A, stir for 30 minutes, put 2×1 (cm) foamed nickel into solution A, transfer to a 100mL reaction kettle, hydrothermally react at 100°C for 12h to obtain the khaki product NiMn-LDH -NF; Take out the foamed nickel, wash with water and alcohol, and dry.

[0034] Weigh NaH 2 PO 2 Place it on the upstream of the semi-closed crucible, place the NiMn-LDH-NF prepared above at the downstream of the semi-closed crucible, NaH 2 PO 2 The ratio of the amount to NiMn-LDH-NF is 5mol:1mol. The crucible is transferred to an automatically ...

Embodiment 2

[0036] The preparation method of the electrocatalytic material is basically the same as in Example 1, except that: NiCl 2 ·6H 2 The mass of O is 0.1783 g (Ni:Mn=3:1). The material is named Ni 3 Mn 1 P-NF.

Embodiment 3

[0038] The preparation method of the electrocatalytic material is basically the same as in Example 1, except that: NiCl 2 ·6H 2 The mass of O is 0.0594 g (Ni:Mn=1:1). The material is named Ni 1 Mn 1 P-NF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com