Steel piece alkaline deep hole nickel plating additive, pre-plating solution and pre-plating technology

A technology of additive and deep hole agent, which is applied in the electroplating field of electrodeposition, can solve problems such as plating solution turbidity, and achieve the effect of easy precipitation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

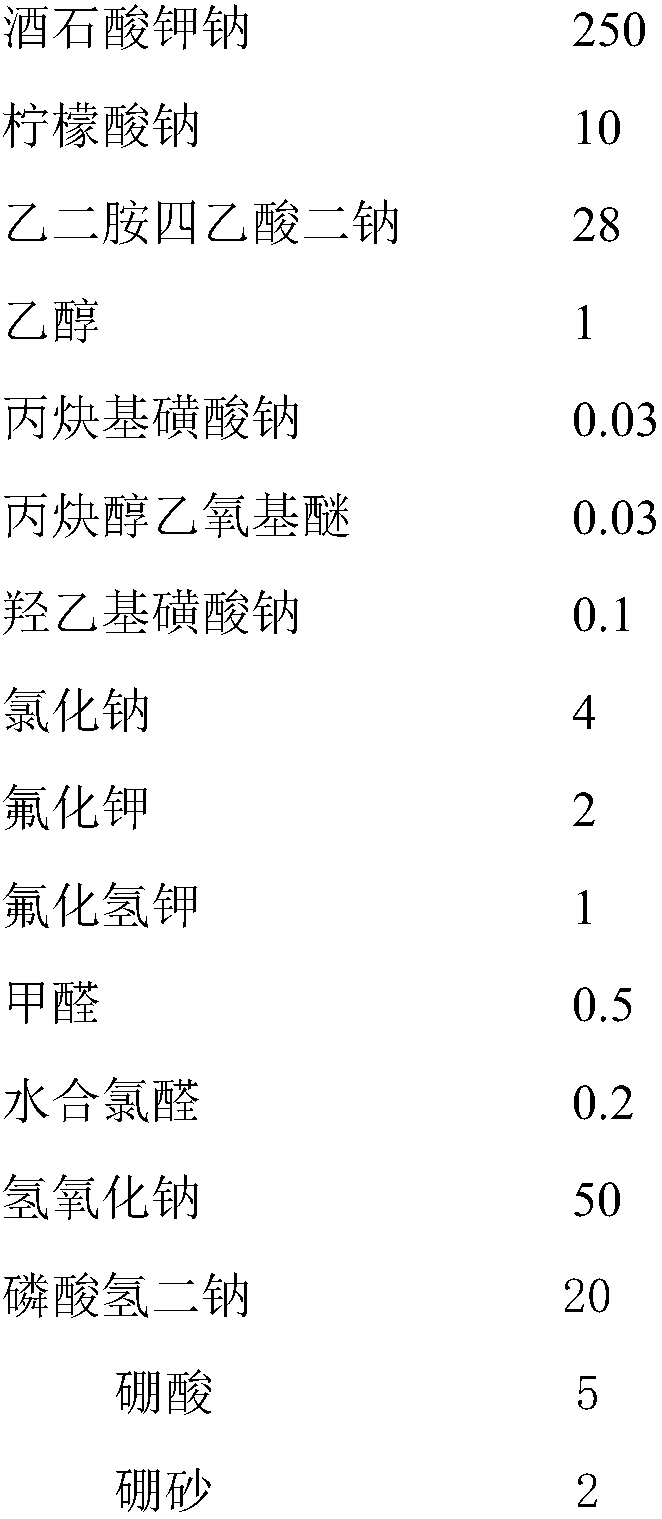

[0034] The alkaline deep-hole nickel plating additive for iron and steel parts of the present embodiment includes a cylinder-opening agent and a deep-hole agent, and the balance is water. Wherein the formula of cylinder opener is as follows:

[0035]

[0036]

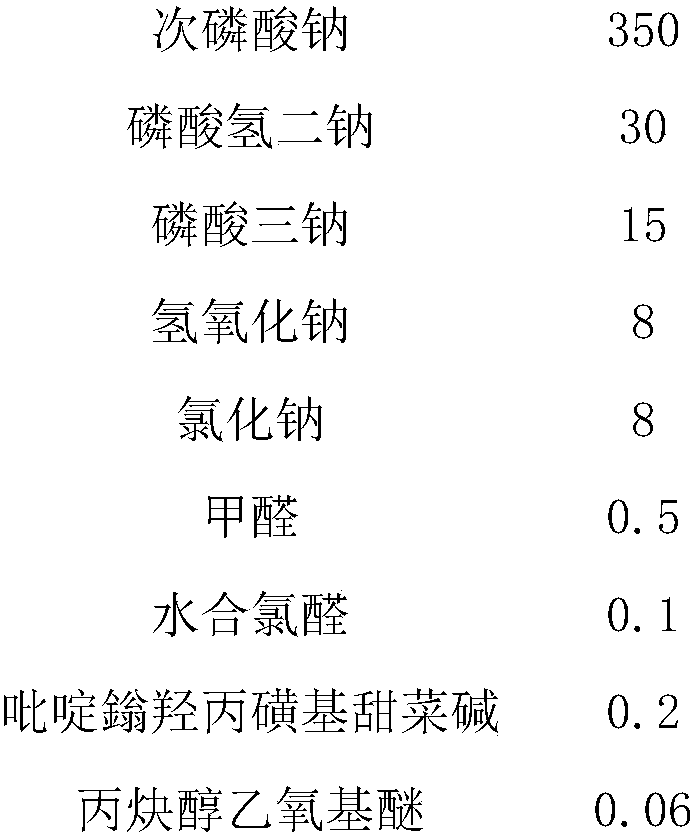

[0037] The formula of deep hole agent is as follows:

[0038]

Embodiment 2

[0040] The alkaline deep-hole nickel plating additive for iron and steel parts of the present embodiment includes a cylinder-opening agent and a deep-hole agent, and the balance is water. Wherein the formula of cylinder opener is as follows:

[0041]

[0042]

[0043] The formula of deep hole agent is as follows:

[0044]

Embodiment 3

[0046] The alkaline deep-hole nickel plating additive for iron and steel parts of the present embodiment includes a cylinder-opening agent and a deep-hole agent, and the balance is water. Wherein the formula of cylinder opener is as follows:

[0047]

[0048]

[0049] The formula of deep hole agent is as follows:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com