Conductive acrylic filament plated with copper-boron alloy and preparation method of conductive acrylic filament

A kind of conductive filament, boron alloy technology, applied in liquid chemical plating, metal material coating process, yarn and other directions, can solve the problems of large pollution, conductive stability, less application, etc., achieve excellent sterilization, deodorization and anti-radiation performance, Good fit and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

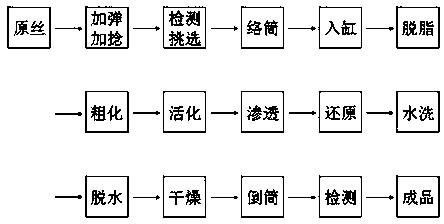

Method used

Image

Examples

preparation example Construction

[0037] A preparation method for acrylic copper-plated-boron alloy conductive filaments, the specific steps comprising:

[0038] 1. The untwisted acrylic filaments are elasticized and twisted. The boiling water shrinkage of the processed filaments is ≤1.0%, the twist is 96Z / m, the strength is 28CN / Tex, and the elongation is 18%. The silk is helpful to the post-processing process, reducing the fuzz or messy yarn on the reel.

[0039] 2. The yarn bobbin after elastic and twisting is then wound onto the loose bobbin. The loose bobbin strives to be completely consistent with the weight of the yarn, the overall size and shape of the bobbin, and the density is controlled at 0.22Kg / dm 3 .

[0040] 3. Place the loose yarn bobbin in a closed container for degreasing treatment in the form of two-way pressure washing.

[0041] 4. Place the loose yarn bobbin in a closed container to micro-etch and roughen the surface of the fiber in the form of two-way pressure washing.

[0042] 5. Plac...

Embodiment 1

[0047] 1. The untwisted acrylic filaments are stretched and twisted on the puller. The shrinkage of the treated filaments in boiling water is ≤1.0%, the twist is 96Z / m, the strength is 28CN / Tex, and the elongation is 18%.

[0048] 2. The bobbin after elastic twisting is wound on the loose bobbin, and the density is controlled at 0.25Kg / dm 3 .

[0049] 3. Place the loose yarn bobbin in a closed container for degreasing treatment in the form of two-way pressure washing. After degreasing treatment, wash it three times with water to centrifugally dehydrate the yarn bobbin.

[0050] 4. Place the loose yarn bobbin in a closed container to micro-etch and roughen the surface of the fiber in the form of two-way pressure washing. After the treatment, wash the bobbin three times with water to centrifugally dehydrate the bobbin.

[0051] 5. Place the loose yarn bobbin in a closed container to activate the fiber under acidic conditions in the form of two-way pressure impregnation.

[005...

Embodiment 2

[0056] The difference from Example 1 is:

[0057] Step 6. Place the loose bobbin in an airtight container to carry out Cu on the surface of the fiber in the form of two-way pressure impregnation. 2+ Dipping. The yarn ratio of each component of the dipping solution is: 50% copper sulfate, 50% ethylenediaminetetraacetic acid, 50% potassium sodium tartrate, 0.12% potassium ferrocyanide, 0.12% pyridine, polyethylene glycol 0.25%, water 400% ~ 800%, appropriate amount of sodium hydroxide to adjust to PH = 11, at a temperature of 40 ° C and a pressure of 0.20 MPa, to achieve Cu 2+ Uniform adsorption, diffusion and penetration from the fiber surface to the inside.

[0058] Step 7. Place the impregnated yarn bobbin in a closed container in the form of two-way pressure impregnation at a temperature of 100°C and a pressure of 0.20MPa to achieve Cu adsorption on the fiber surface 9 S 5 The complexation formation, the yarn ratio of each component of the complexation reaction solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powerful | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com