GaN-based LED structure and preparation method thereof

An LED structure, N-type technology, used in electrical components, circuits, semiconductor devices, etc., can solve problems such as restricting development, LED luminous efficiency attenuation, and restricting the development of high-power LEDs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

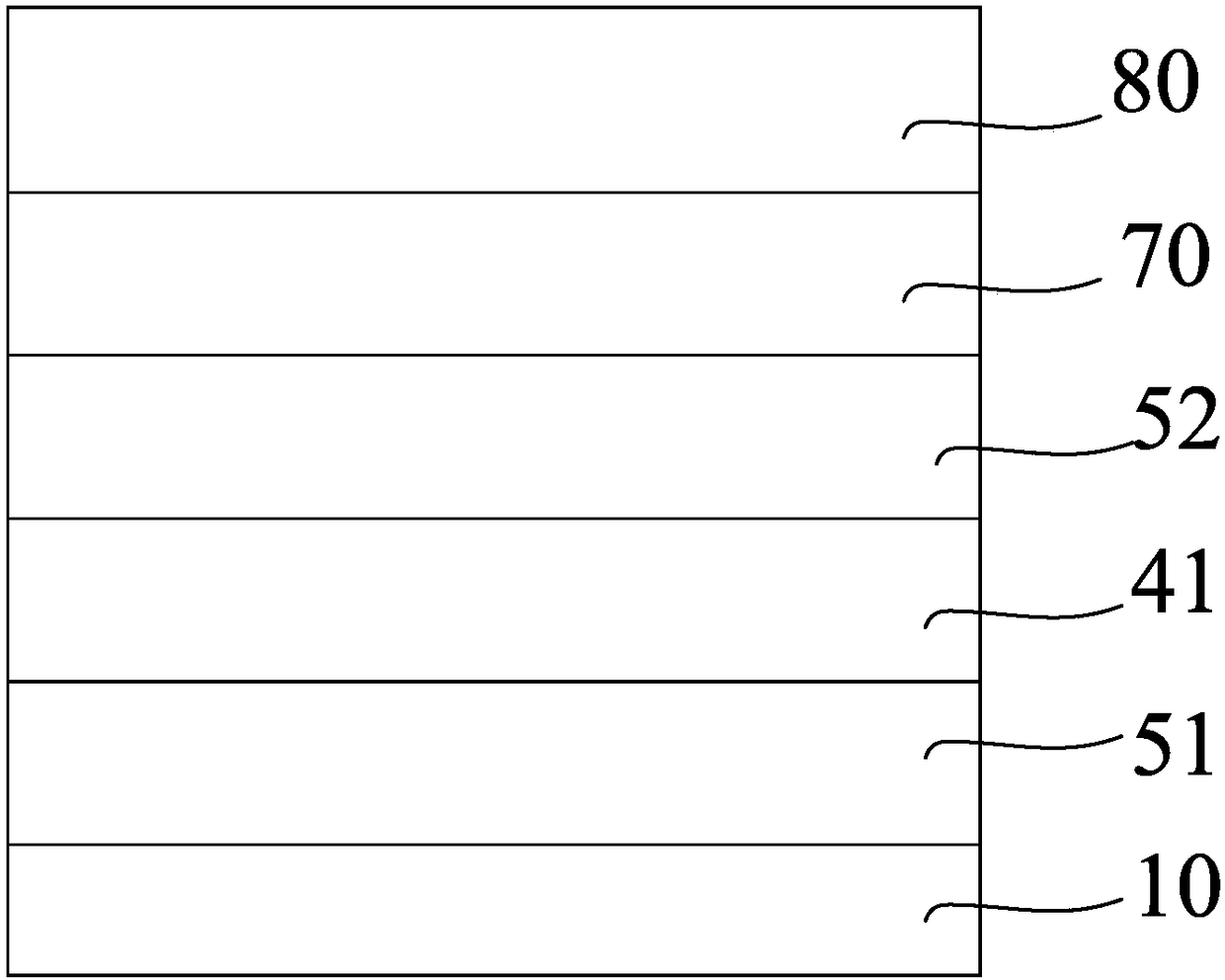

[0041] The embodiment of the present invention also provides a method for preparing the GaN-based LED structure, comprising the following steps:

[0042] providing a substrate 10; and

[0043] On the substrate 10, the first N-type doped GaN layer 51, the first ZnGeN 2 The barrier layer 41 , the second N-type doped GaN layer 52 , the multi-quantum well layer 70 and the P-type doped GaN layer 80 .

[0044] In one embodiment, before growing the first N-type doped GaN layer 51, the following steps are further included:

[0045] epitaxially growing a buffer layer 20 on said substrate 10; and

[0046] epitaxially grow a second ZnGeN on the buffer layer 20 2 barrier layer 42 .

[0047] The growth temperature of the buffer layer may range from 950°C to 1050°C. In one embodiment, after the buffer layer 30 and before growing the first N-type doped GaN layer 51 , a step of growing a leveling layer is further included. The growth temperature of the leveling layer 30 may be 1050°C-11...

Embodiment

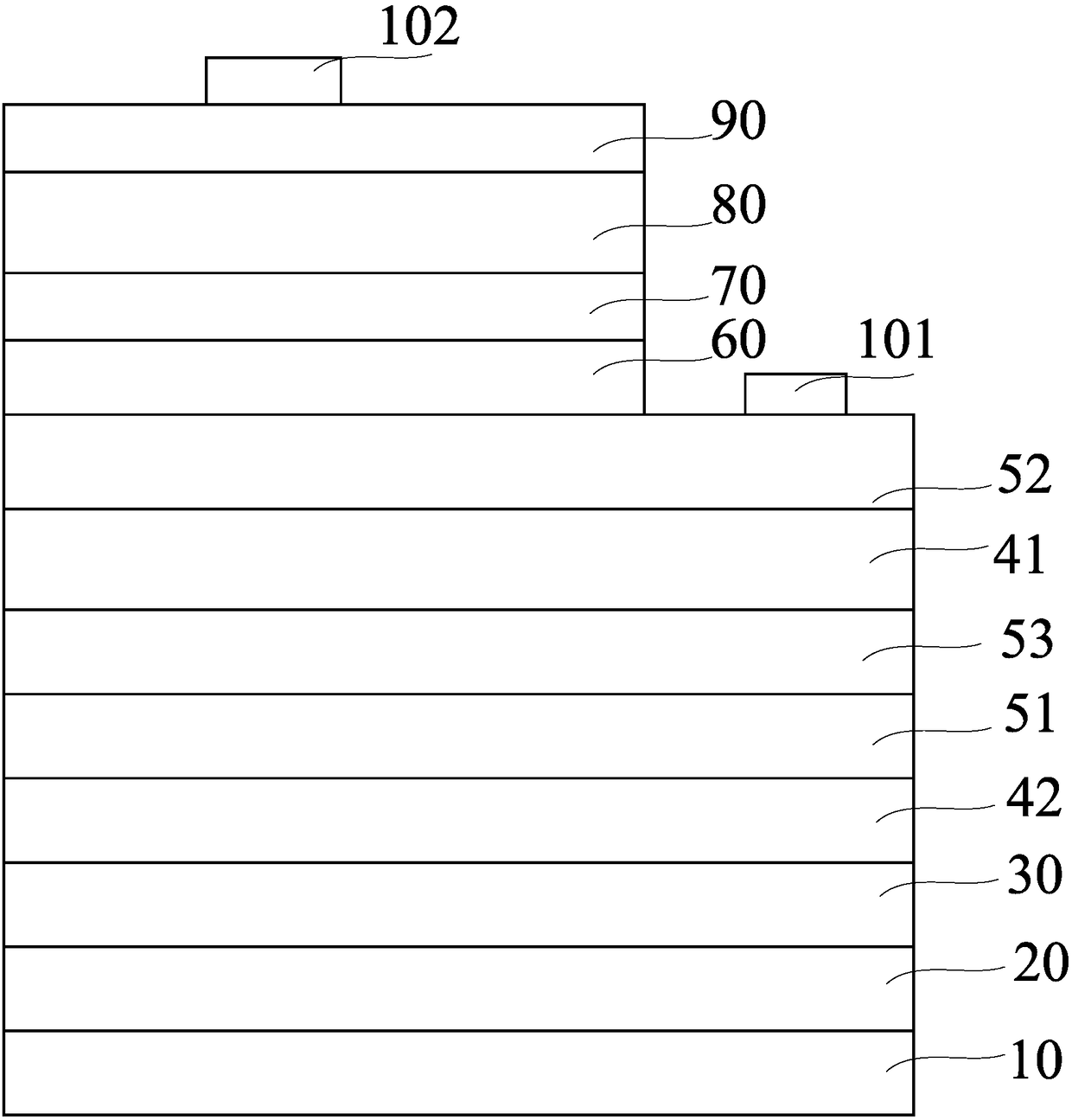

[0057] (1) providing a sapphire substrate 10;

[0058] (2) Cu is evaporated onto the sapphire substrate 10 by electron beam deposition (PVD);

[0059] (3) grow a layer of 20nm graphene layer under the condition of 540 DEG C by chemical vapor deposition (CVD);

[0060] (4) feed ammonia gas, hydrogen gas and trimethylgallium, and grow a 20nm buffer layer 20 on the graphene layer at 1000°C;

[0061] (5) inject ammonia gas, hydrogen gas and trimethylgallium, and grow a 1.5 μm leveling layer 30 on the buffer layer 20 at 1080° C.;

[0062] (6) Feed ammonia gas, hydrogen gas, Zn metal vapor and Ge metal vapor, grow the second ZnGeN of 5.5nm on the buffer layer 30 at 900°C 2 barrier layer 42;

[0063] (7) into silane (SiH 4 ), ammonia gas, hydrogen gas and trimethylgallium, growing a 0.8um first doped N-type doped GaN layer 51 on the buffer layer 20 at 1080°C;

[0064] (8) into silane (SiH 4 ), ammonia gas, hydrogen gas and trimethylgallium, and grow the third doped N-type doped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com