Metal halide perovskite-polycarbonate composite fluorescent film as well as preparation method and application thereof

A metal halide and polycarbonate technology, applied in chemical instruments and methods, luminescent materials, coatings, etc., can solve problems such as high temperature and complex preparation process, improve dispersibility and filler ratio, and inhibit non-radiative recombination. , the effect of improving uniformity and fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A metal halide perovskite-polycarbonate composite fluorescent film is prepared by the following steps:

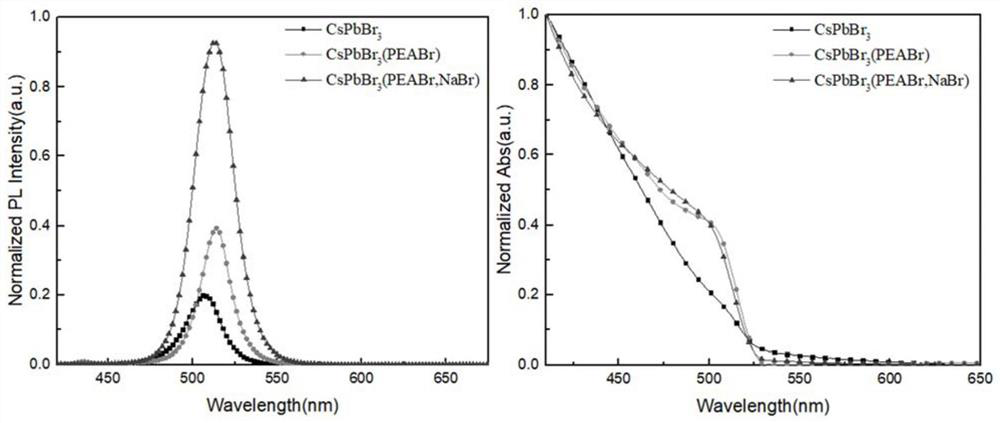

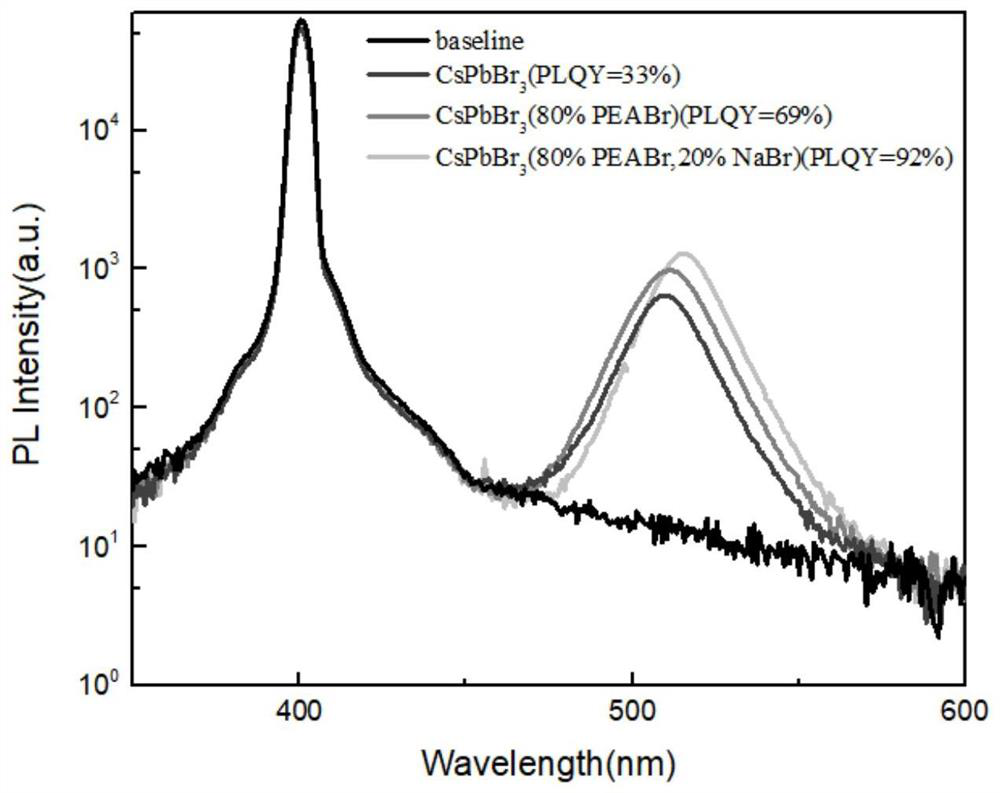

[0041] (1) Preparation of perovskite precursor solution: phenethylamine bromide (PEABr), CsBr, PbBr 2 and NaBr were respectively dissolved in the solvent DMSO, and the concentration was controlled to be 0.1 mole per liter. CsBr, PbBr 2 After the solution is mixed, an appropriate amount of DMSO is added to dilute to form CsPbBr 3 Precursor, CsBr:PbBr 2 The molar ratio is 1.6:1; CsBr, PbBr 2 , PEABr solution is mixed and then diluted with appropriate amount of DMSO to form CsPbBr 3(PEABr) Precursor, CsBr:PbBr 2 :PEABr molar ratio is 1.6:1:0.8; CsBr, PbBr 2 , PEABr, and NaBr solutions are mixed and then diluted with an appropriate amount of DMSO to form CsPbBr 3 (PEABr, NaBr) precursor, CsBr:PbBr 2 :PEABr:NaBr molar ratio is 1.6:1:0.8:0.2. PbBr in the precursor solution composed of three different components exemplified above 2 The molar concentration is 0.02 ...

Embodiment 2

[0050] With CsBr in embodiment 1:PbBr 2 :PEABr:NaBr is 1.6:1:0.8:0.2 as an example to compare the effect of heating spin coating at different temperatures. The preparation process of the precursor solution, the preparation and treatment process of the polycarbonate film, and the preparation process of the composite film after preheating are the same as in Example 1.

[0051] Preheating at different temperatures: During the preparation of composite fluorescent films, the CsPbBr 3 (PEABr, NaBr) precursor solution, anti-solvent chlorobenzene, and PC film were preheated on a hot stage at 30°C and 80°C for 15-20min, respectively.

[0052] Figure 5 CsPbBr after preheating at 30°C and 80°C, respectively 3 (PEABr, NaBr)-PC composite fluorescent film absorption spectrum and fluorescence emission spectrum under 400nm excitation, it can be seen that the fluorescence intensity and absorption of the film after 80 ℃ preheating treatment are higher, and the higher fluorescence intensity ...

Embodiment 3

[0057] The preparation and processing process of the polycarbonate film and the preparation process of the composite fluorescent film are the same as in Example 1, the difference lies in the preparation of the perovskite precursor solution and the selection of the anti-solvent type.

[0058] Preparation of perovskite precursor solution: PEABr (phenethyl ammonium bromide), CsI, PbI 2 They were respectively dissolved in the solvent DMSO, and the concentration was controlled to be 0.1 moles per liter. PEABr, CsI, PbI 2 The three solutions were blended according to the ratio of (0~1):1:1 and diluted with appropriate amount of DMSO to form CsPbI 3 (PEABr) precursor solution, PbI in the precursor solution 2 The molar concentration is 0.02 moles per liter.

[0059] Selection of the type of anti-solvent: The difference from Example 1 is that ethyl acetate is used instead of chlorobenzene as the anti-solvent.

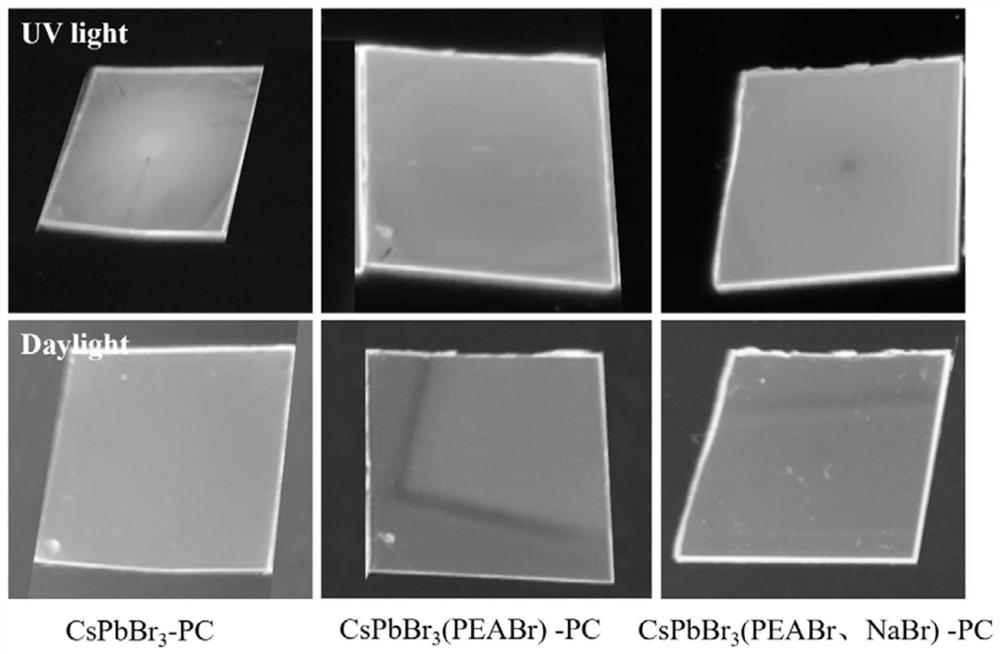

[0060] Figure 7 It is the optical photograph of the composite film un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com