A perovskite light-emitting diode with mixed cations and mixed anions and its preparation method

A technology of light-emitting diodes and mixed cations, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as performance gaps, achieve reduced density, be suitable for large-scale applications, and have simple preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

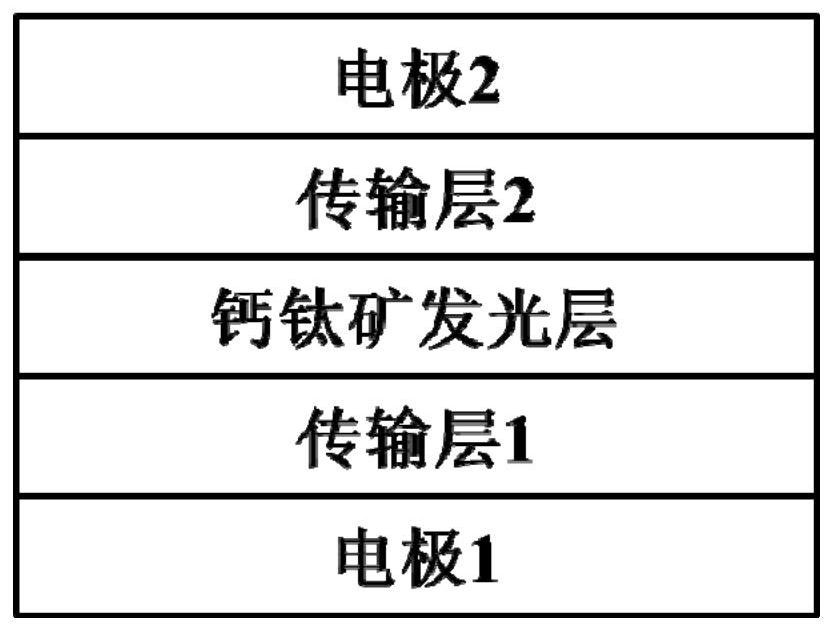

[0050] A method for preparing a perovskite light-emitting diode with mixed cations and mixed anions, comprising the following steps:

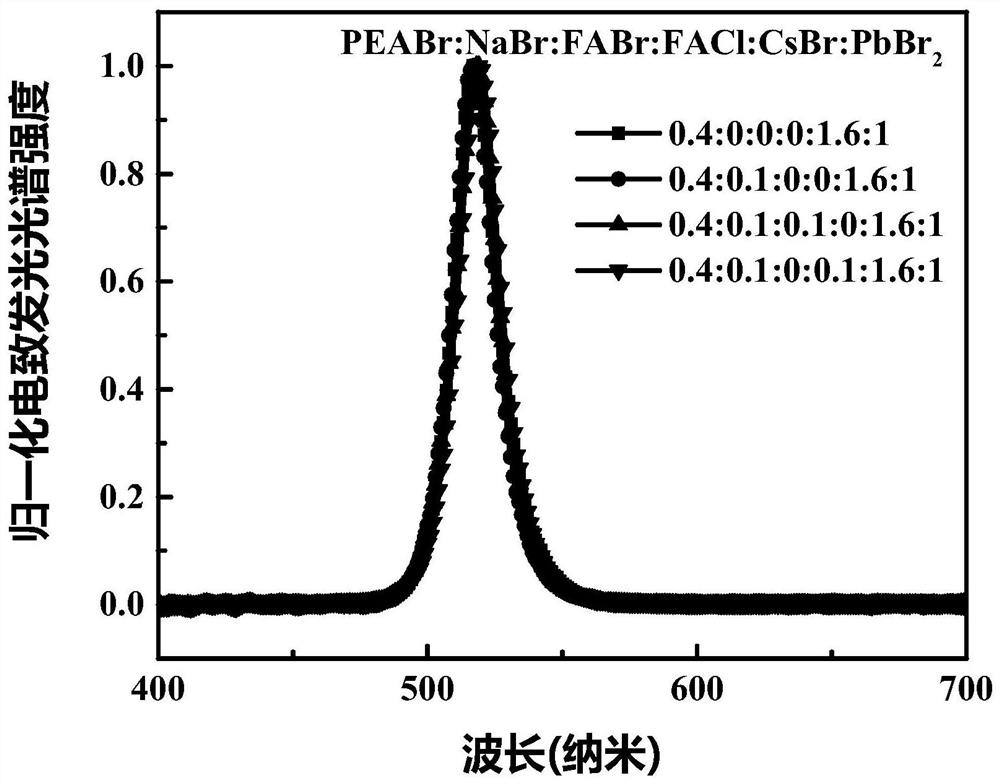

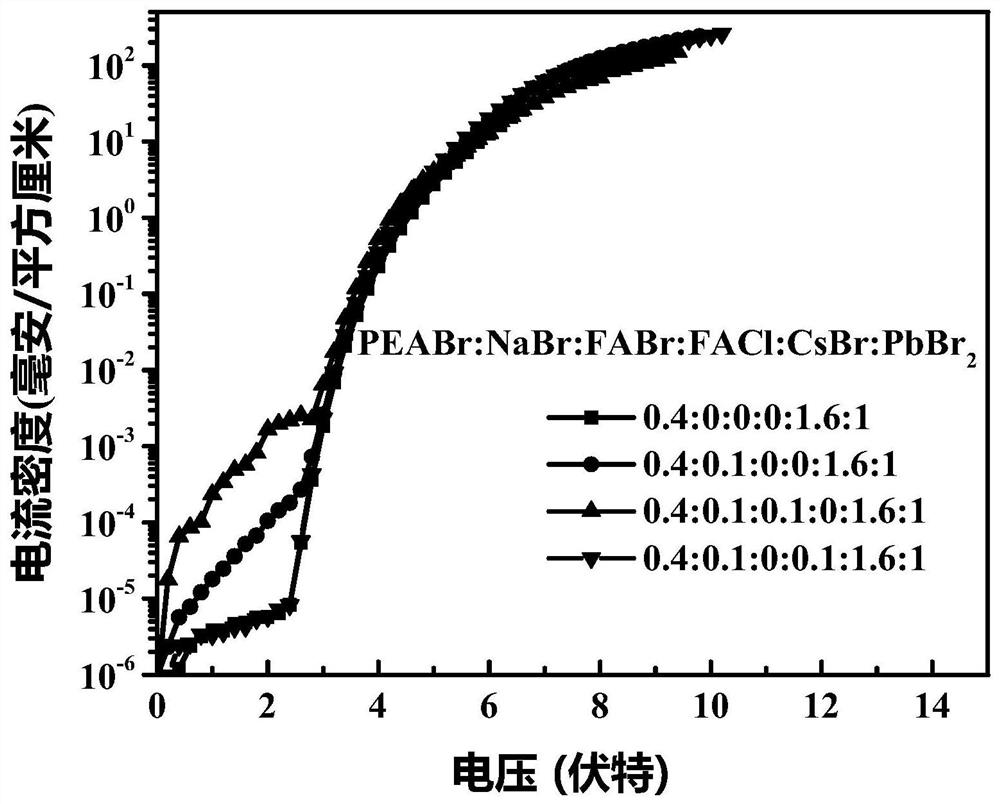

[0051] (1) Preparation of perovskite precursor solution: PEABr (phenethylamine bromide), NaBr, FABr (formamidine bromide), FACl (formamidine chloride), CsBr, PbBr 2 According to 0.4:0:0:0:1.6:1, 0.4:0.1:0:0:1.6:1, 0.4:0.1:0.1:0:1.6:1, 0.4:0.1:0:0.1:1.6:1 respectively The molar ratio is dissolved in the solvent DMSO, where PbBr 2 The molar concentration of the solution was 0.3 moles per liter, and the solution was stirred on a hot stage at 45° C. for 12 hours, then the solution was cooled to room temperature, allowed to stand, and the supernatant liquid was taken and filtered. The specific formulations of the four perovskite precursor solutions are shown in Table 1.

[0052] Table 1. Formulations of four perovskite precursor solutions (unit: moles per liter)

[0053]

[0054] (2) Preparation of nickel oxide precursor solution: Dissolve 0.4...

Embodiment 2

[0063] The device structure and preparation method are basically the same as in Example 1, the difference lies in the preparation of the perovskite light-emitting layer precursor solution. The specific formula of the perovskite precursor solution is shown in Table 3, and the mixed cation is also Na + 、Cs + and FA + , the mixed anion is also Br - and Cl - , but the chloride ion comes from PEACl (phenethylammonium chloride).

[0064] Table 3. Recipe of perovskite precursor solution (unit: mol per liter)

[0065]

[0066] Figure 6 is the emission spectrum of the device, Figure 7 , Figure 8 and Figure 9 They are the current density-voltage, luminance-voltage, external quantum efficiency-luminance characteristic curves of the device, and the corresponding device performance parameters are shown in Table 4. The results showed that this mixed cation (Na + 、Cs + and FA + ) and mixed anions (Br - and Cl - , the maximum external quantum efficiency of perovskite light...

Embodiment 3

[0070] The device structure and preparation method are basically the same as the examples, except that the preparation of the perovskite light-emitting layer precursor solution, the specific formula of the perovskite precursor solution is shown in Table 5, and the mixed cation is Na + 、Cs + and FA + , the mixed anion is Br - and Cl - , the chloride ion comes from NaCl.

[0071] Table 5. Recipe of perovskite precursor solution (unit: mol per liter)

[0072]

[0073] Figure 10 is the emission spectrum of the device, Figure 11 , Figure 12 and Figure 13 They are the current density-voltage, luminance-voltage, external quantum efficiency-luminance characteristic curves of the prepared devices, respectively, and the corresponding device performance parameters are shown in Table 6. The results showed that this mixed cation (Na + 、Cs + and FA + ) and mixed anions (Br - and Cl - , the maximum external quantum efficiency of the perovskite light-emitting diodes with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com