Heterojunction solar cell and manufacturing method thereof

A technology for solar cells and heterojunctions, which can be used in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve the problems of low solar energy conversion efficiency, narrow band gap, and poor passivation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention. The singular forms "a", "an" and "the" include plural referents unless the context clearly dictates otherwise.

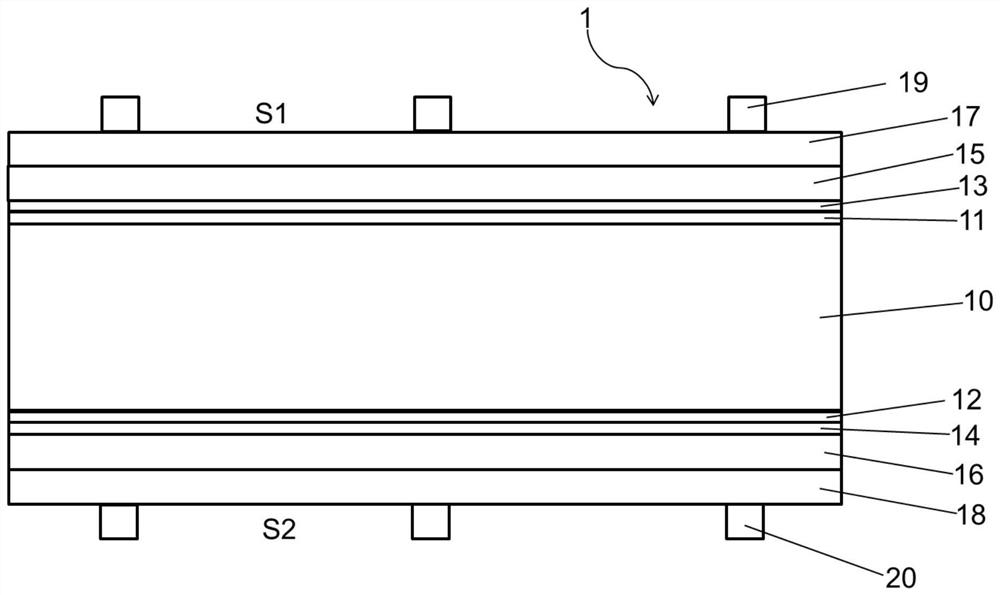

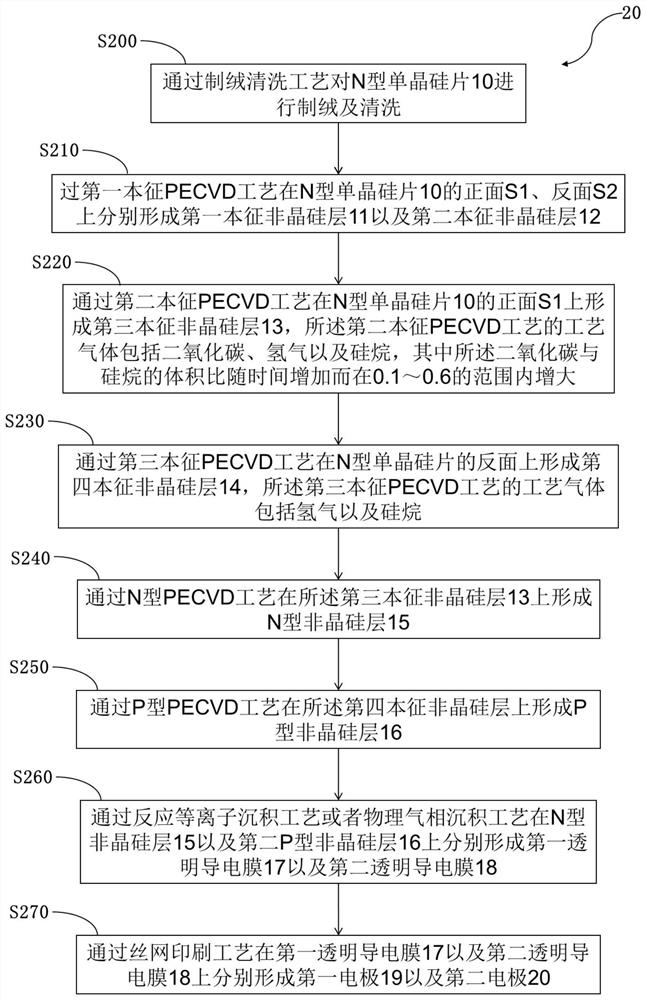

[0031] see figure 1 , which shows a schematic diagram of the composition and structure of the heterojunction solar cell of the present invention. like figure 1 As shown, the heterojunction solar cell 1 includes an N-type monocrystalline silicon wafer 10 . A first intrinsic amorphous silicon layer 11, a third intrinsic amorphous silicon layer 13, an N-type amorphous silicon layer 15, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com