Grain boundary passivation method of perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of perovskite thin film charge recombination, performance degradation of photovoltaic devices, etc., achieve reduction of internal defect state density, passivation of perovskite grain boundaries, and simple method easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Cleaning of the conductive substrate: Use detergent, deionized water, acetone, ethanol, and isopropanol in sequence to ultrasonically clean the etched FTO glass for 15-20 minutes. After cleaning, dry the glass with a nitrogen gun. Then carry out UVO treatment for 25min~30min;

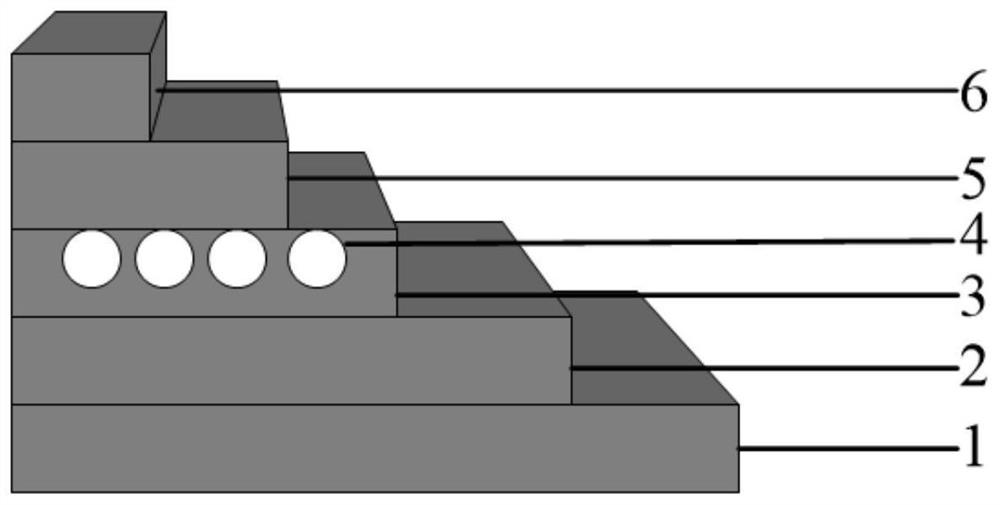

[0029] 2. TiO2 2 Preparation of the electron transport layer: Stir 125 μL diisopropoxybisacetylacetonate titanium solution and 1590 μL n-butanol for 1 h, then drop the mixed solution onto the FTO glass and rotate at 500 rpm for 3 s, then at 2000 rpm for 30 s, and finally Annealing at 135°C for 10 minutes, followed by sintering at 500°C for 30 minutes to obtain TiO 2 dense layer, the TiO 2 After the mesoporous film substrate was treated with ozone for 20 min, it was transferred to N 2 Ambient glove box;

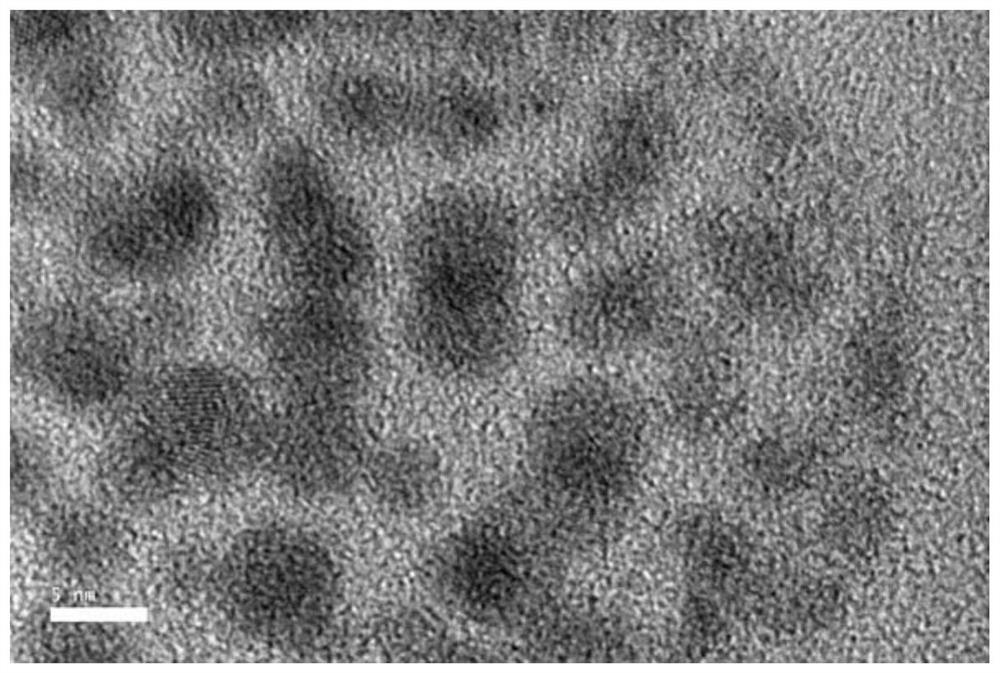

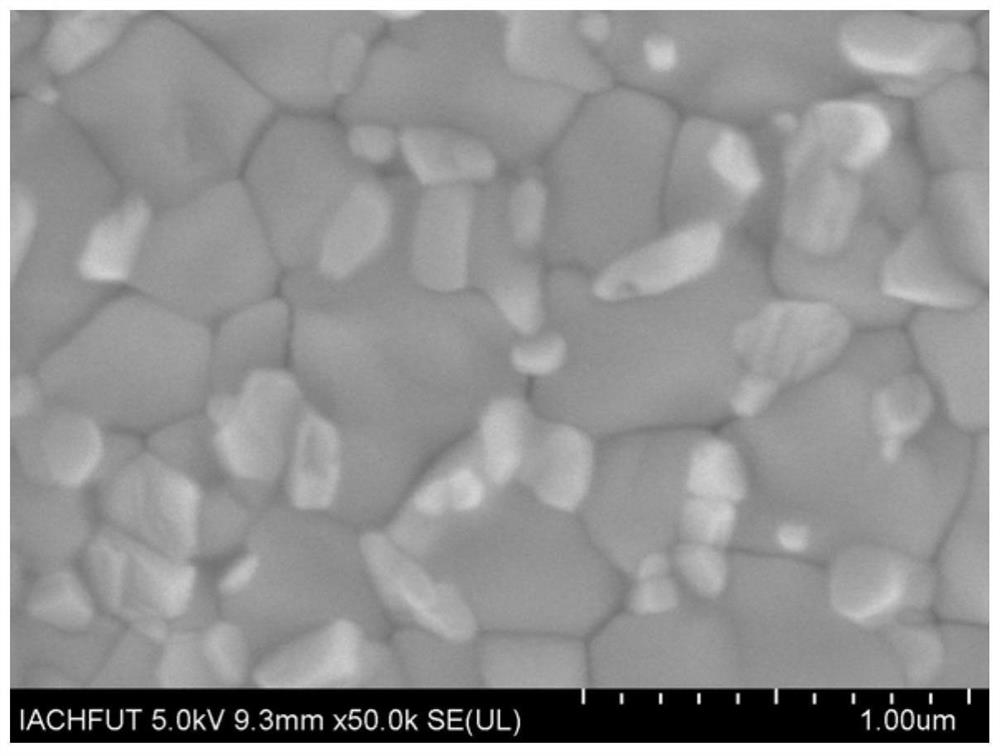

[0030] 3. Preparation of perovskite layer: 100mL MAPbI 3 Perovskite precursor solution covered with TiO 2 On the electron transport layer, spin coating was performed at a rotation speed ...

Embodiment 2

[0037] 1. Cleaning of the conductive substrate: Use detergent, deionized water, acetone, ethanol, and isopropanol in sequence to ultrasonically clean the etched FTO glass for 15-20 minutes. After cleaning, dry the glass with a nitrogen gun. Then carry out UVO treatment for 25min~30min;

[0038] 2. Preparation of different electron transport layers: (1) TiO 2 : Stir 125 μL titanium diisopropoxybisacetylacetonate solution and 1590 μL n-butanol for 1 hour, then drop the mixed solution onto the FTO glass and rotate at 500 rpm for 3 seconds, then rotate at 2000 rpm for 30 seconds, and finally anneal at 135 ° C for 10 minutes. Then sintered at 500°C for 30min to obtain TiO 2 Dense layer; (2) SnO 2 : Will commercially use SnO 2 The hydrosol and deionized water were mixed and diluted according to the volume ratio of 1:7, and then spin-coated on the cleaned FTO at a speed of 3000rpm for 30s. After the spin coating is finished, place it on a heating platform and heat it at 150°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com