Sodium-ion battery anode material and preparation method and application thereof

A sodium ion battery and negative electrode material technology, applied in the field of electrochemistry, can solve the problem of low charge and discharge capacity of the negative electrode material of sodium ion battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of a negative electrode material for a sodium ion battery, comprising the steps of:

[0031] (1) providing a mixed aqueous solution comprising divalent transition metal ions and trivalent transition metal ions, the divalent transition metal ions comprising Co 2+ , Fe 2+ or Ni 2+ , the trivalent transition metal ions include Fe 3+ 、Co 3+ or Mn 3+ , the molar ratio of the divalent transition metal ion to the trivalent transition metal ion is 2 to 3:1;

[0032] (2) Under a protective atmosphere, the pH value of the mixed aqueous solution is adjusted to 8 to obtain a pre-reaction solution;

[0033] (3) performing crystallization reaction, washing and drying on the pre-reaction liquid in sequence to obtain hydrotalcite;

[0034] (4) Sintering the hydrotalcite and cooling to obtain the negative electrode material of the sodium ion battery.

[0035] The present invention firstly provides a mixed aqueous solution containing div...

Embodiment 1

[0055] Weigh 22.84g CoCl 2 ·6H 2 O and 13.33g Fe(NO 3 ) 3 9H 2 O (Co / Fe molar ratio = 3), dissolved in 600mL of carbon dioxide deionized water to obtain a mixed salt solution;

[0056] Weigh 12g NaOH and dissolve it in 200mL decarbonated deionized water to form a sodium hydroxide aqueous solution with a concentration of 1.5M; control the dropping speed at 1.6mL / min, and drop the sodium hydroxide aqueous solution into the mixed salt solution under nitrogen protection. The pH value of the mixed aqueous solution is 8 to obtain a pre-reaction solution;

[0057] Move the pre-reaction solution into an autoclave, seal it, place it in an oven at 130°C, take it out after 24 hours of reaction, wash the reaction product 3 times with deionized water to remove carbon dioxide, and wash it once with absolute ethanol, and put the precipitate Put it in an oven at 60°C overnight to get hydrotalcite;

[0058] Put the hydrotalcite in a muffle furnace at 400°C and keep it warm for 4 hours to...

Embodiment 2

[0066] Prepare the negative electrode material of sodium ion battery according to the method of Example 1, and test the composition, morphology and performance of hydrotalcite and the negative electrode material of sodium ion battery, the difference is that when preparing the mixed salt solution, weigh 11.42g CoCl 2 ·6H 2 O and 6.66g Fe(NO 3 ) 3 9H 2 O (Co / Fe molar ratio = 3), dissolved in 300 mL decarbonated deionized water.

[0067] The elements of the hydrotalcite and the negative electrode material of the sodium ion battery are analyzed, and the results show that the composition of the hydrotalcite is: Co 0.58 Fe 0.26 (OH) 2 (NO 3 ) 0.18 0.32H 2 O, (Co / Fe molar ratio=3:1); the negative electrode material of sodium ion battery is Fe 3 o 4 @Co 3 o 4 (Co / Fe molar ratio=3:1).

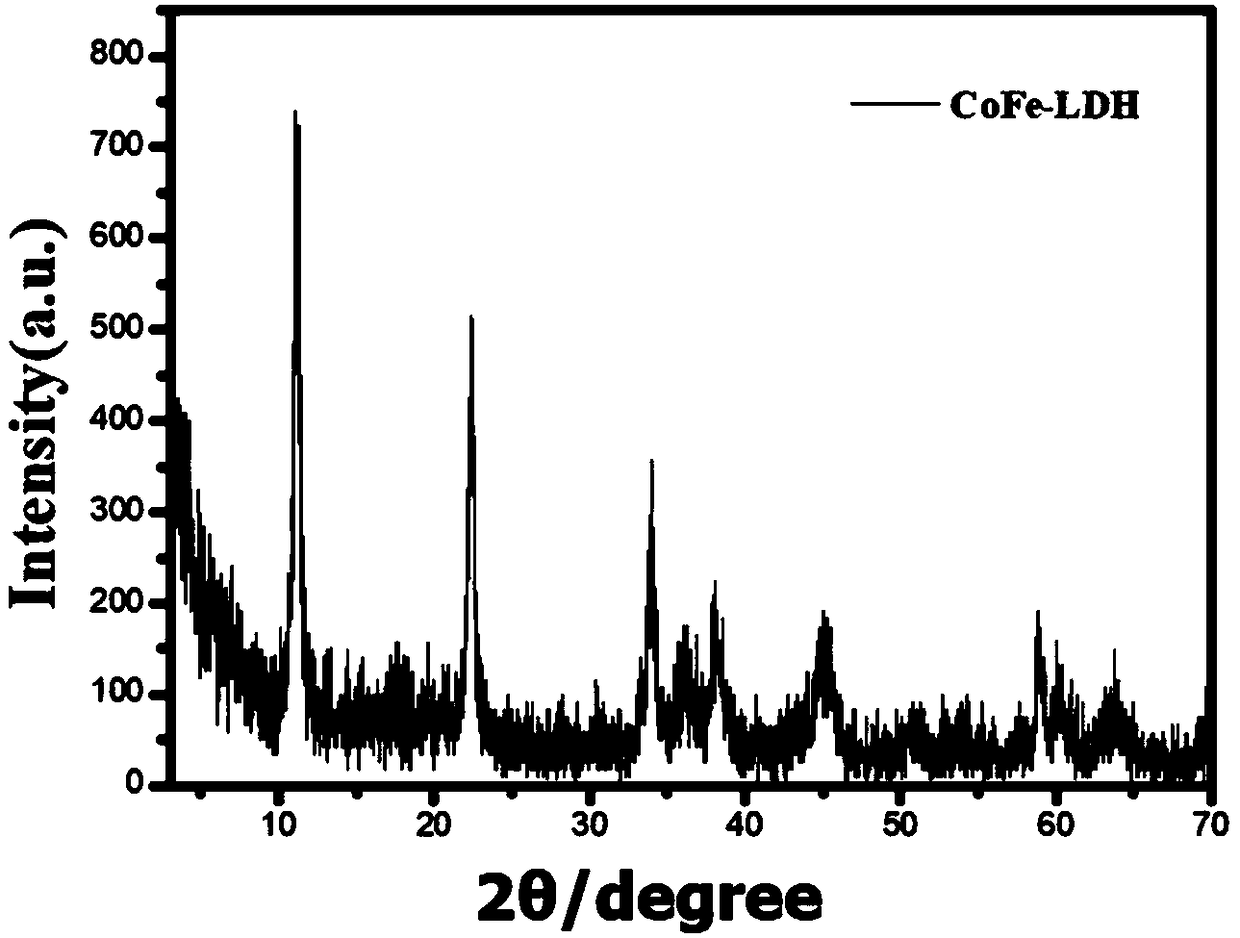

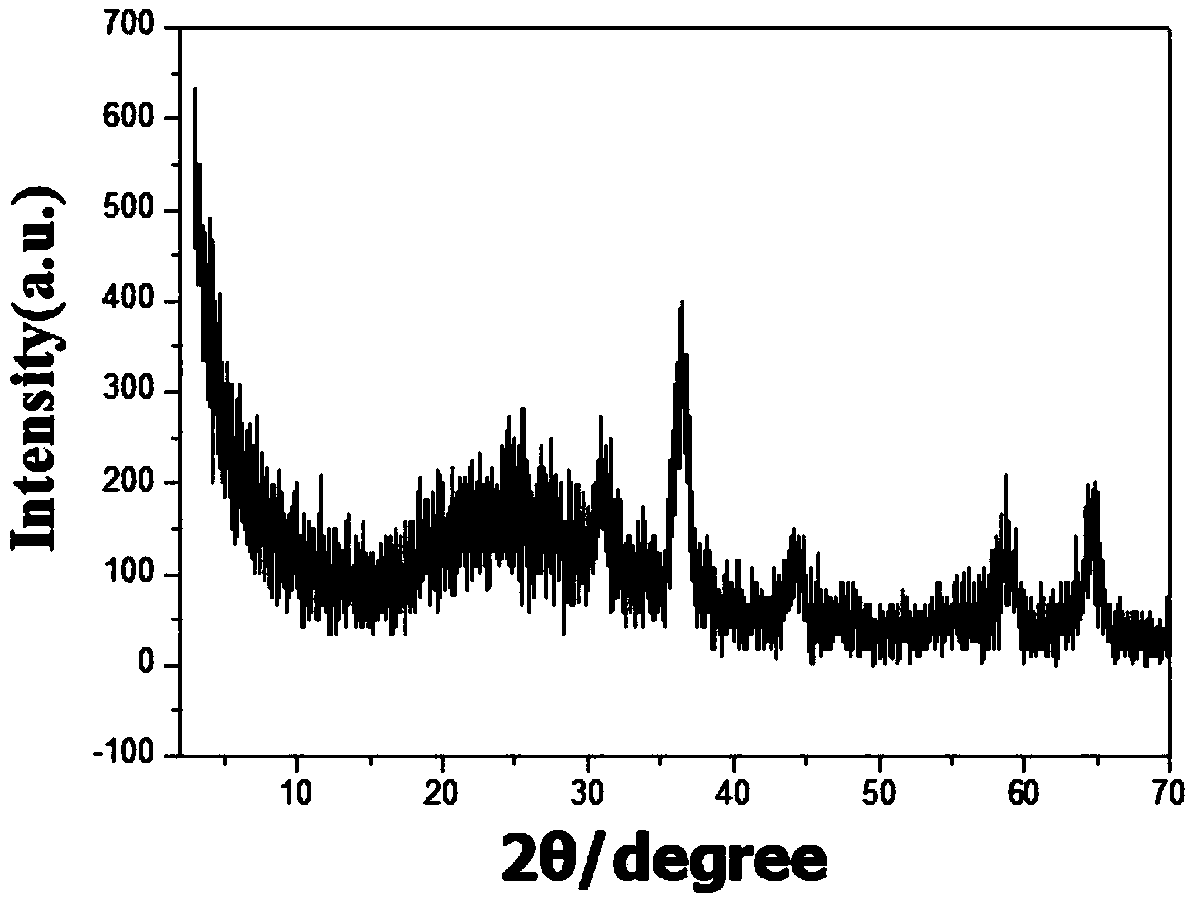

[0068] The hydrotalcite and sodium-ion battery anode materials were characterized by XRD and SEM, respectively. In the XRD diagram, the peaks are high and sharp, indicating that the crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com