AgPd nano-alloy formate oxidation catalyst and treatment method of non-surfactant for improving catalytic activity

A technology of oxidation catalyst and nano-alloy, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of inhibiting catalytic activity and the performance of Pd-based catalysts is not obvious, and achieve the effect of improving catalytic performance and FOR catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

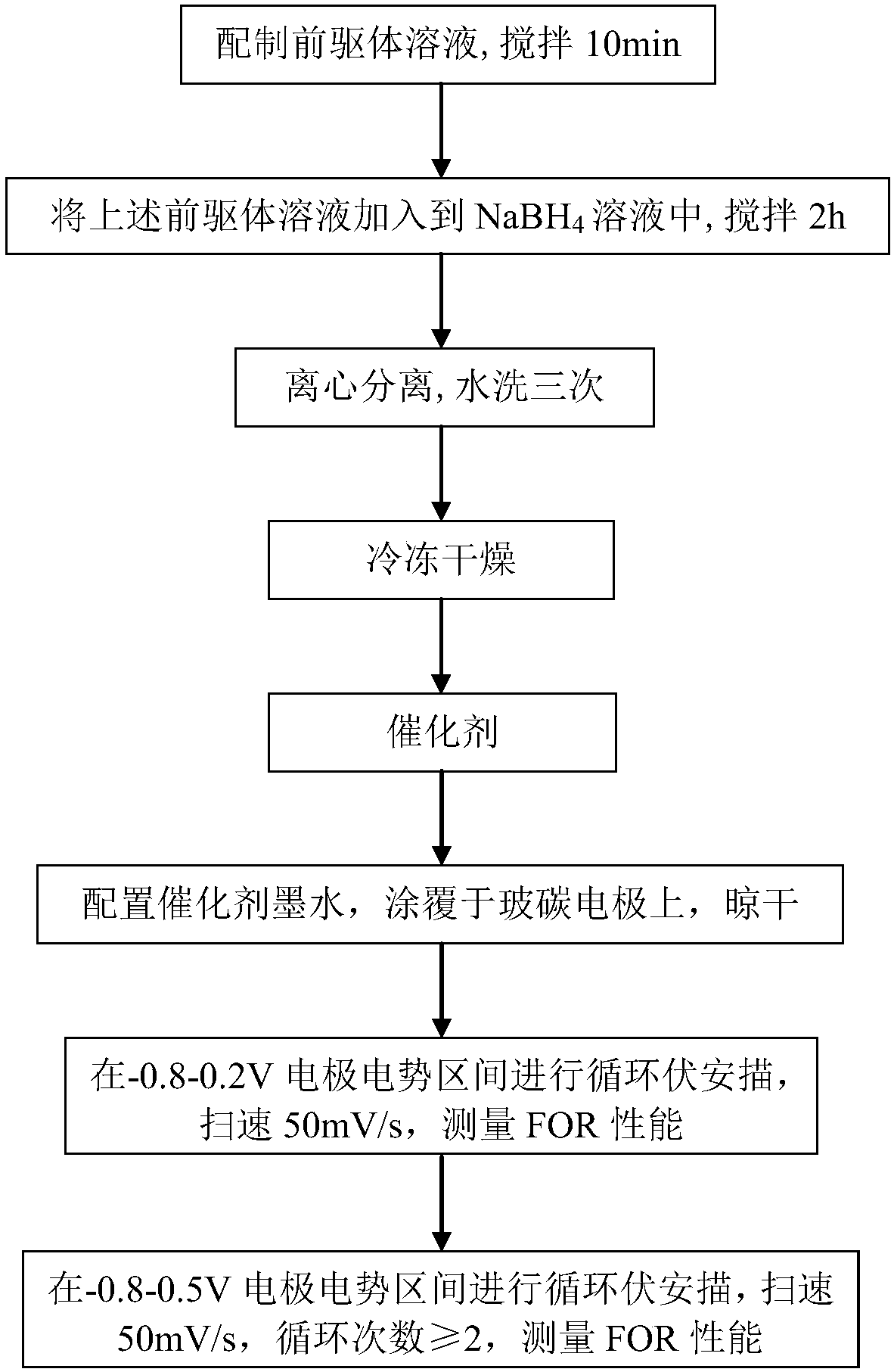

Method used

Image

Examples

example 1

[0043] 1 g of 99% AgNO 3 Dissolved in 58.9mL deionized water to prepare a 0.1mol / L aqueous solution, 1g of 99% Pd(NO 3 ) 2 Dissolved in 43.1mL deionized water to prepare a 0.1mol / L aqueous solution, 0.25g 99% NaBH 4 Dissolve in 66mL of deionized water to prepare a 0.1mol / L aqueous solution. Take the above AgNO 3 Aqueous solution, Pd(NO 3 ) 2 The aqueous solution was mixed and stirred for 10 minutes (volume ratio 3:1) and added dropwise to NaBH 4 In aqueous solution, stir at room temperature for 2h until the reaction is complete. Then the solution was centrifuged (4000rpm, 3min), washed three times with plasma water, freeze-dried for 12h, and ground to obtain Pd 0.34 Ag 0.66 catalyst. Weigh 2mg Pd 0.34 Ag 0.66 The catalyst is dispersed in a mixed solution of deionized water and absolute ethanol, 20 microliters of 5% membrane solution is added dropwise, ultrasonicated for 30 minutes, and then coated on a glassy carbon electrode, and dried at room temperature. In the ...

example 2

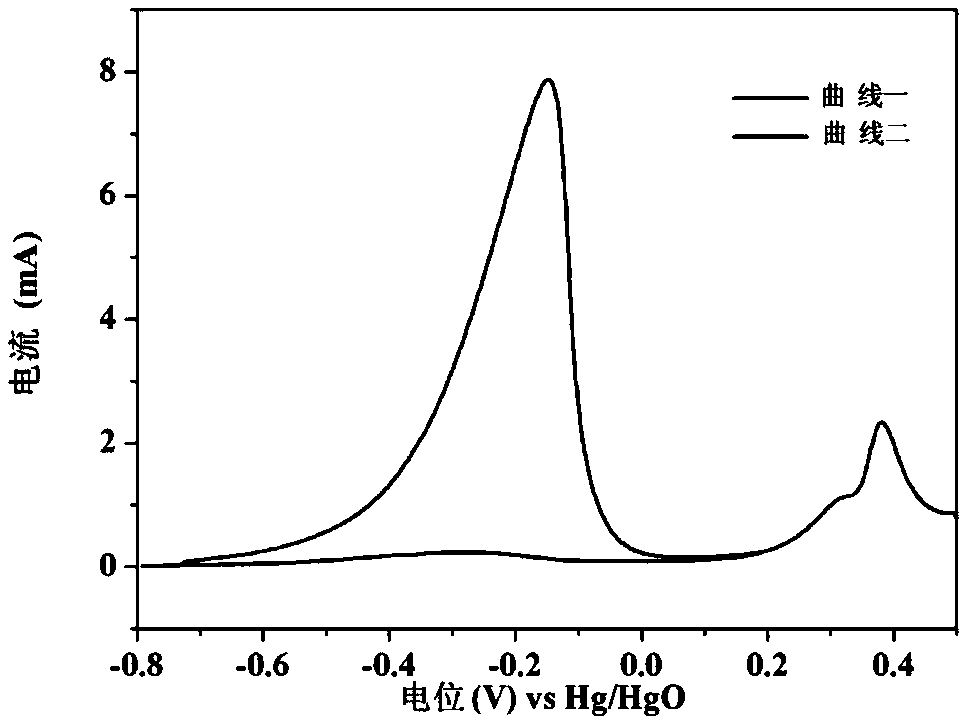

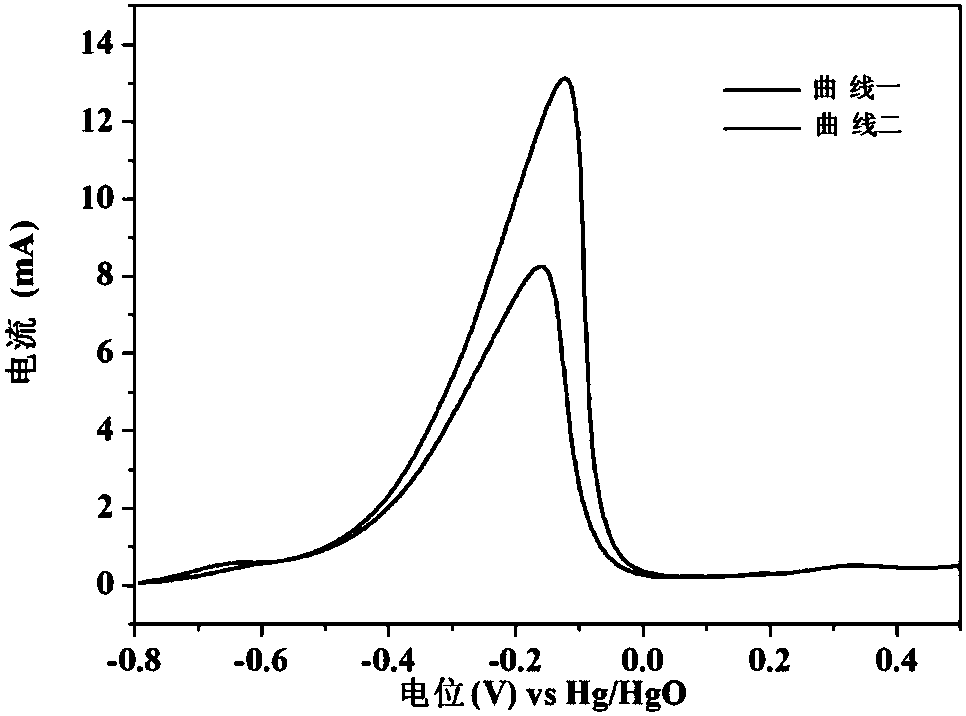

[0045] Take the above AgNO 3 Aqueous solution, Pd(NO 3 ) 2 The aqueous solution was mixed and stirred for 10 minutes (volume ratio 1:1) and added dropwise to NaBH 4 In aqueous solution, stir at room temperature for 2h until the reaction is complete. Then the solution was centrifuged (4000rpm, 3min), washed three times with plasma water, freeze-dried for 12h, and ground to obtain Pd 0.5 Ag 0.5 catalyst. Weigh 2mg Pd 0.5 Ag 0.5 The catalyst is dispersed in a mixed solution of deionized water and absolute ethanol, 20 microliters of 5% membrane solution is added dropwise, ultrasonicated for 30 minutes, and then coated on a glassy carbon electrode, and dried at room temperature. In the lower electrode potential interval -0.8-0.2V (relative to the Hg / HgO electrode), a cyclic voltammetry scan was performed at a scan rate of 50mV / s to measure the FOR performance (see image 3 Curve 1). On this basis, the electrode potential range was expanded to -0.8-0.5V (relative to the Hg / ...

example 3

[0047] Take the above AgNO 3 Aqueous solution, Pd(NO 3 ) 2 The aqueous solution was mixed and stirred for 10 minutes (volume ratio 3:1) and added dropwise to NaBH 4 In aqueous solution, stir at room temperature for 2h until the reaction is complete. Then the solution was centrifuged (4000rpm, 3min), washed three times with plasma water, freeze-dried for 12h, and ground to obtain Pd 0.66 Ag 0.34 catalyst. Weigh 2mg Pd 0.66 Ag 0.34 The catalyst is dispersed in a mixed solution of deionized water and absolute ethanol, 20 microliters of 5% membrane solution is added dropwise, ultrasonicated for 30 minutes, and then coated on a glassy carbon electrode, and dried at room temperature. In the lower electrode potential interval -0.8-0.2V (relative to the Hg / HgO electrode), a cyclic voltammetry scan was performed at a scan rate of 50mV / s to measure the FOR performance (see Figure 4 Curve 1). On this basis, the electrode potential range was expanded to -0.8-0.5V (relative to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak current | aaaaa | aaaaa |

| Electrode area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com