Preparation method of nickel nitride graphene composite material-loaded previous metal nanoparticle

A technology of graphene nanosheets and composite materials, which is applied in the field of materials science, can solve the problems of high price and low catalytic activity of catalysts, achieve the effect of simple and clear preparation process, and improve electrochemical activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

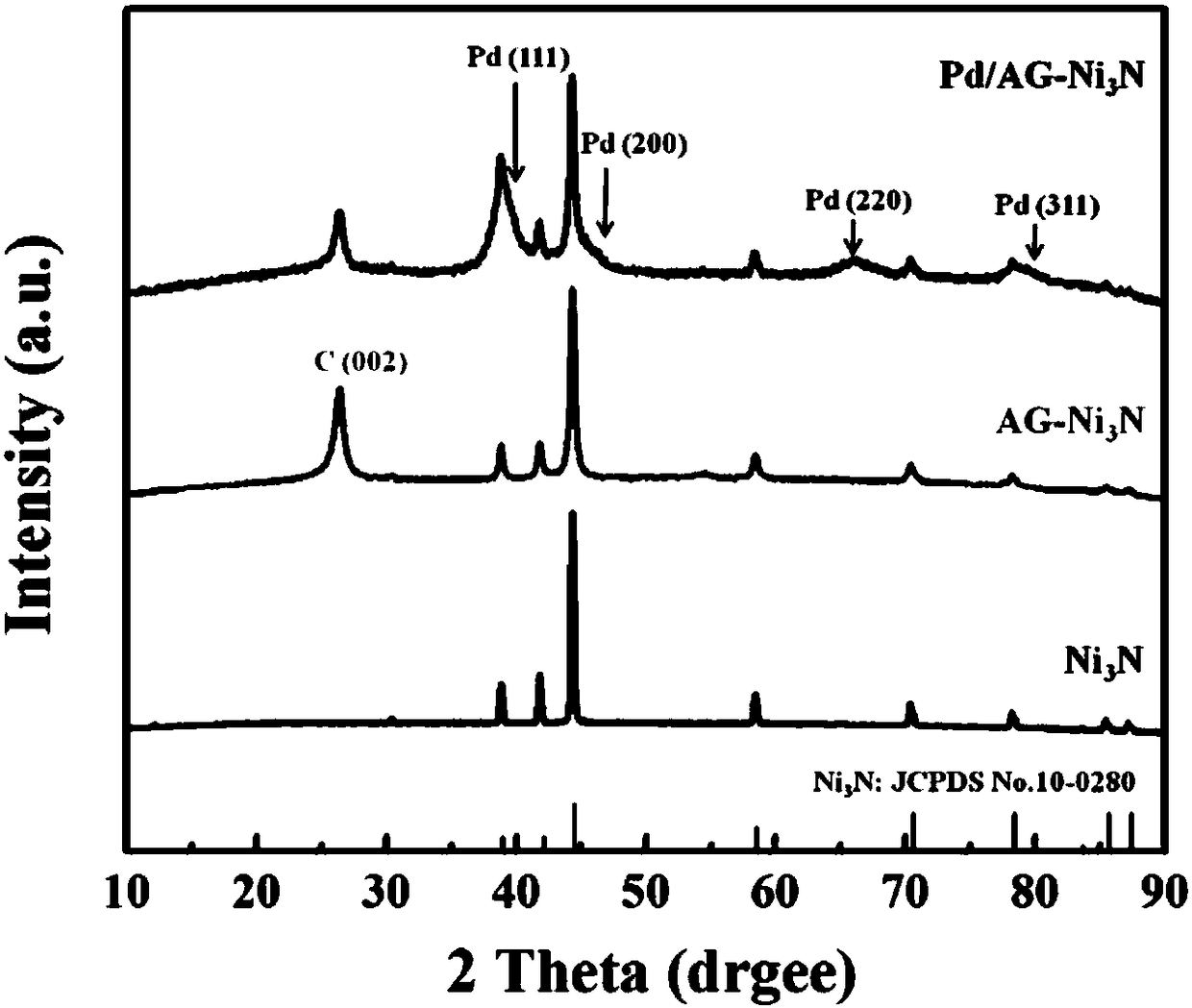

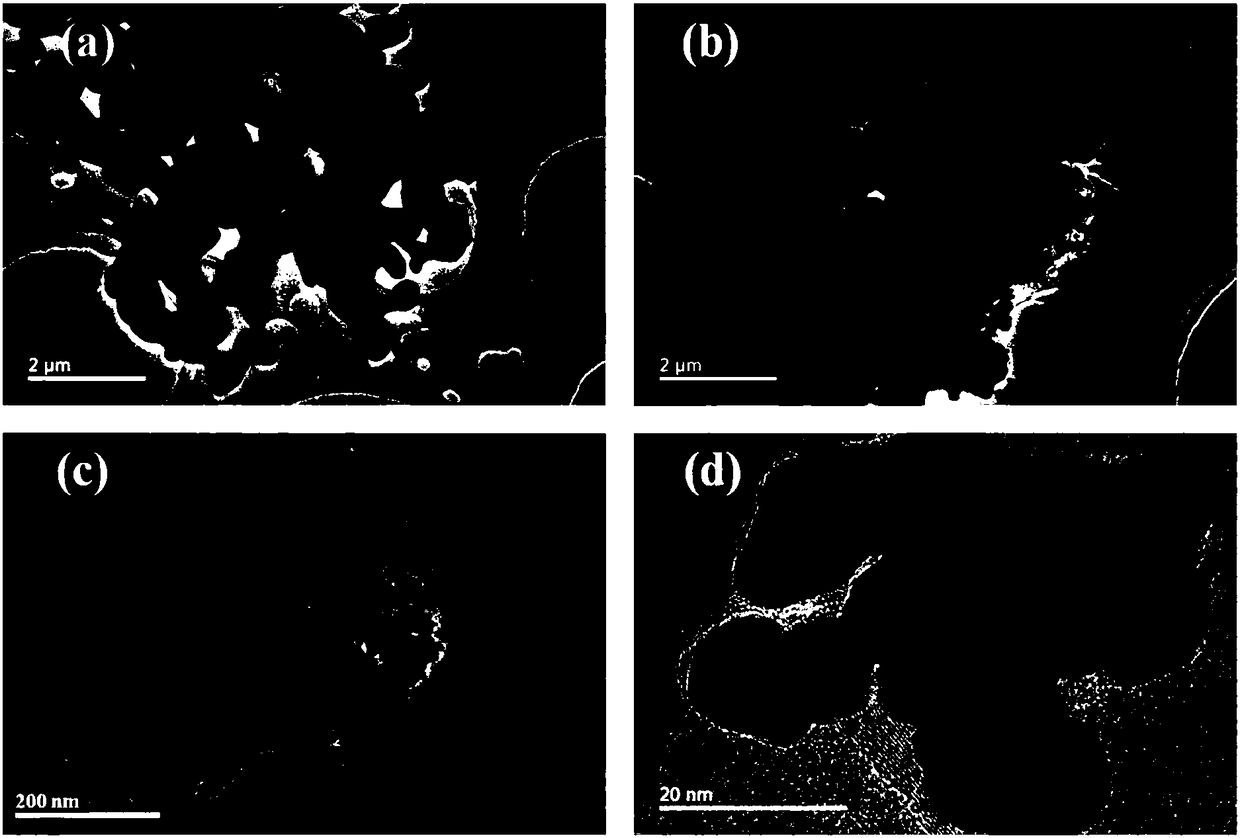

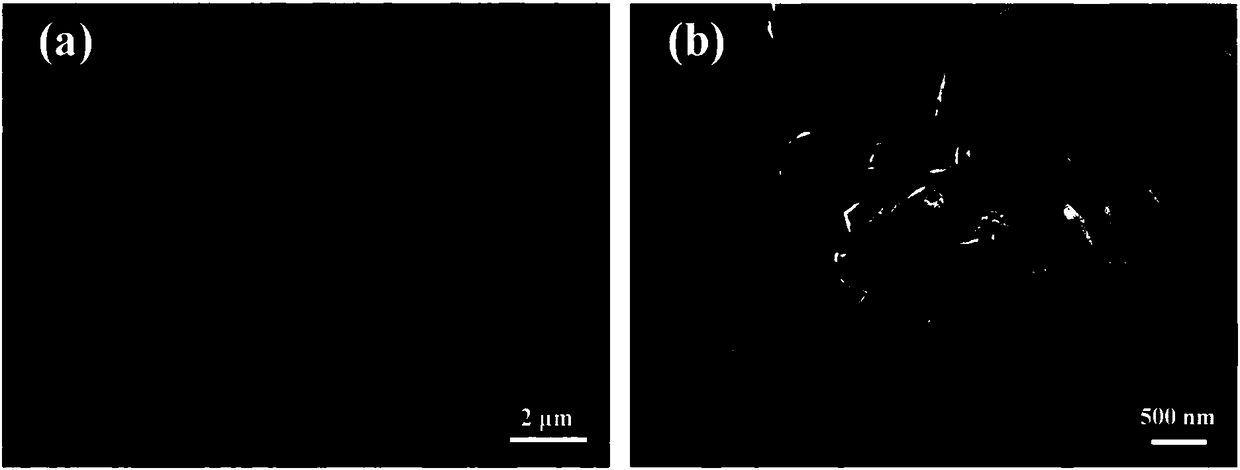

[0025] A preparation method of nickel nitride graphene composite material loaded noble metal nanoparticles, specifically comprising the following steps:

[0026] (1) Preparation of nickel nitride graphene composites

[0027] ① Preparation of nickel nitride: 0.594g of nickel chloride hexahydrate (NiCl 2 ·6H 2 O), 0.185g ammonium chloride (NH 4 Cl) and 0.75g of urea were dissolved in 50ml of deionized water. After ultrasonic dispersion, they were heated in a hydrothermal kettle at 120°C for 6 hours, and then dried at 80°C after taking them out. Heat the dried sample at 250°C in the air for 2 hours, collect the product after cooling to room temperature, then use a tube furnace to raise the temperature to 380°C under an ammonia atmosphere and keep it for 1 hour, and the product collected after natural cooling is Ni 3 N.

[0028] ② Graphene activation method: immerse graphene in 6M potassium hydroxide solution for 12 hours, and centrifuge the obtained samples with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com