A kind of preparation method of dibenzo-18-crown-6 grafted polyvinyl alcohol microporous membrane

A technology of polyvinyl alcohol and microporous membranes, applied in fuel cells, electrical components, electrochemical generators, etc., can solve problems such as poor stability, unseen problems, and damage to polymer matrix properties, so as to improve thermal stability , Improve ion exchange capacity and conductivity, and inhibit excessive swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

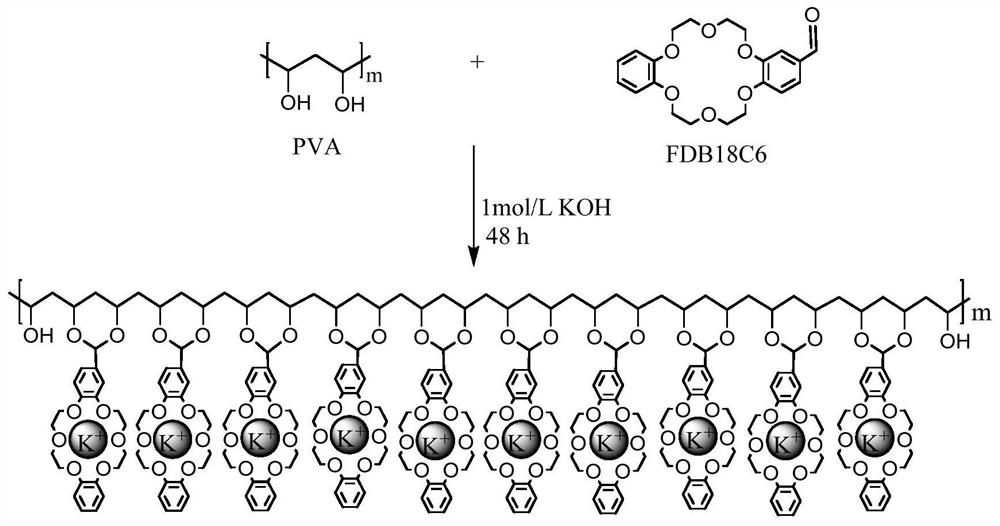

[0055] (1) Heat the constant-temperature heating magnetic stirrer to 95°C for later use; place dibenzo-18crown 6 (0.02mol / L) and hexamethamine (0.08mol / L) in a 100mL circular tube equipped with the above-mentioned magnetic stirrer Quickly add concentrated hydrochloric acid (10mol / L) to the three-neck flask at the bottom, and reflux for 12 hours under the protection of high-purity nitrogen to obtain a brown viscous liquid; after the reaction is completed and cooled to room temperature, add 50 mL of concentrated NaOH solution in sequence and deionized water 200mL, fully stirred until a brown solid appeared, filtered off the water phase, and spin-dried the solid to obtain the crude product 4-formyldibenzo-18-crown 6.

[0056] (2) Add 3.8g of polyvinyl alcohol and 0.2g of 4-formyl dibenzo-18 crown 6 into a 100mL three-necked flask, use 30mL of dimethylformamide (DMF) as a solvent, and heat to 90°C until they are completely dissolved. After the reaction was completed, the solution ...

Embodiment 2

[0058] (1) Heat the constant-temperature heating magnetic stirrer to 95°C for later use; place dibenzo-18crown 6 (0.02mol / L) and hexamethamine (0.08mol / L) in a 100mL circular tube equipped with the above-mentioned magnetic stirrer Quickly add concentrated hydrochloric acid (10mol / L) to the three-neck flask at the bottom, and reflux for 12 hours under the protection of high-purity nitrogen to obtain a brown viscous liquid; after the reaction is completed and cooled to room temperature, add 50 mL of concentrated NaOH solution in sequence and deionized water 200mL, fully stirred until a brown solid appeared, filtered off the water phase, and spin-dried the solid to obtain the crude product 4-formyldibenzo-18-crown 6.

[0059] (2) Add 3.6 g of polyvinyl alcohol and 0.4 g of 4-formyl dibenzo-18 crown 6 into a 100 mL three-necked flask, use 30 mL of dimethylformamide (DMF) as a solvent, and heat to 90° C. until they are completely dissolved. After the reaction was completed, the sol...

Embodiment 3

[0061] (1) Heat the constant temperature heating magnetic stirrer to 95°C for later use; put dibenzo-18crown 6 (0.02mol / L) and urotropine (0.08mol / L) in a 100mL round-bottomed three-port container equipped with mechanical stirring In the bottle, quickly add concentrated hydrochloric acid (10mol / L), and reflux for 12 hours under the protection of high-purity nitrogen to obtain a brown viscous liquid; after the reaction is completed and cooled to room temperature, add 50 mL of concentrated NaOH solution and remove 200 mL of ionic water, fully stirred until a brown solid appeared, filtered off the water phase, and spin-dried the solid to obtain the crude product 4-formyldibenzo-18-crown 6.

[0062] (2) Add 3.4 g of polyvinyl alcohol and 0.6 g of 4-formyl dibenzo-18 crown 6 into a 100 mL three-necked flask, use 30 mL of dimethylformamide (DMF) as a solvent, and heat to 90° C. until they are completely dissolved. After the reaction was completed, the solution was placed on a clean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com