Modified polymer electrolyte membrane, preparation method thereof and modified gel polymer electrolyte material

A technology of electrolyte membrane and polymer, which is applied in electrolytes, circuits, electrical components, etc., can solve the problems of poor electrochemical stability and ionic conductivity, which affect the application, and achieve good electrochemical stability, long cycle life, and ionic The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a modified polymer electrolyte membrane, comprising the following steps:

[0026] After mixing polyvinylidene fluoride-hexafluoropropylene, polycarbonate lactone and polar organic solvent, ultrasonication and stirring are performed in sequence to obtain a polymer solution;

[0027] Casting the polymer solution into a film to obtain a modified polymer electrolyte wet film;

[0028] The modified polymer electrolyte wet membrane is dried to obtain a modified polymer electrolyte membrane.

[0029] In the invention, polyvinylidene fluoride-hexafluoropropylene, polycarbonate lactone and polar organic solvent are mixed, followed by ultrasonication and stirring in sequence to obtain a polymer solution. In the present invention, the number average molecular weight of the polyvinylidene fluoride-hexafluoropropylene is preferably 40000-60000, more preferably 50000; the number average molecular weight of the polycarbonate lactone is pr...

Embodiment 1

[0044] Dissolve 5 g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) in 40 g of N,N-dimethylformamide (DMF), sonicate for 5 minutes, and stir magnetically for 12 hours at room temperature to obtain a solution of polyvinylidene fluoride-hexafluoropropylene ; Polypropylene carbonate (PPC) 5g was dissolved in polyvinylidene fluoride-hexafluoropropylene solution, ultrasonicated for 5 min, and magnetically stirred at room temperature for 12 hours to obtain a polymer solution;

[0045] Transfer the polymer solution into a clean Teflon mold (200mm×200mm), cast it naturally, and place it at room temperature for 30 minutes to stabilize the composite polymer system to obtain a modified polymer electrolyte wet film;

[0046] The obtained modified polymer electrolyte wet membrane was dried in a vacuum oven at 80° C. for 24 hours to obtain a modified polymer electrolyte membrane with a thickness of about 50 μm.

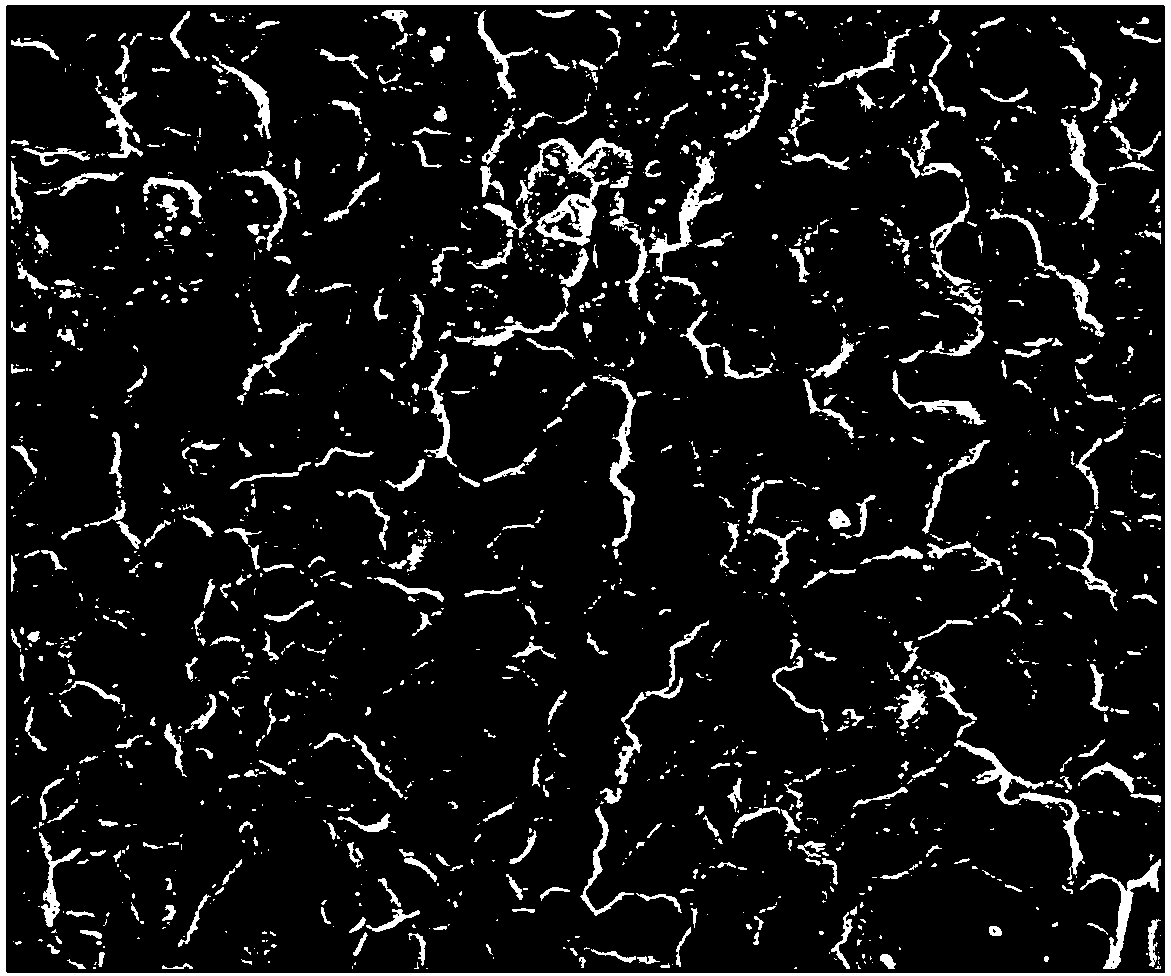

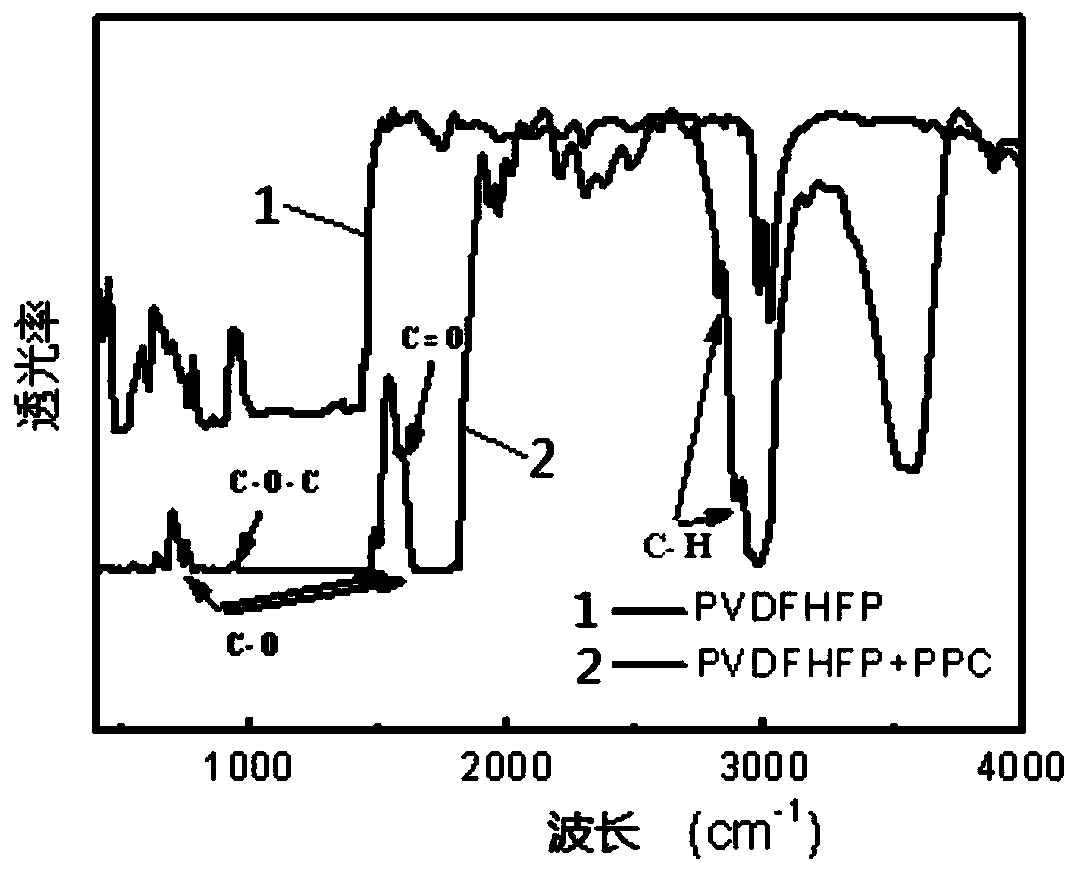

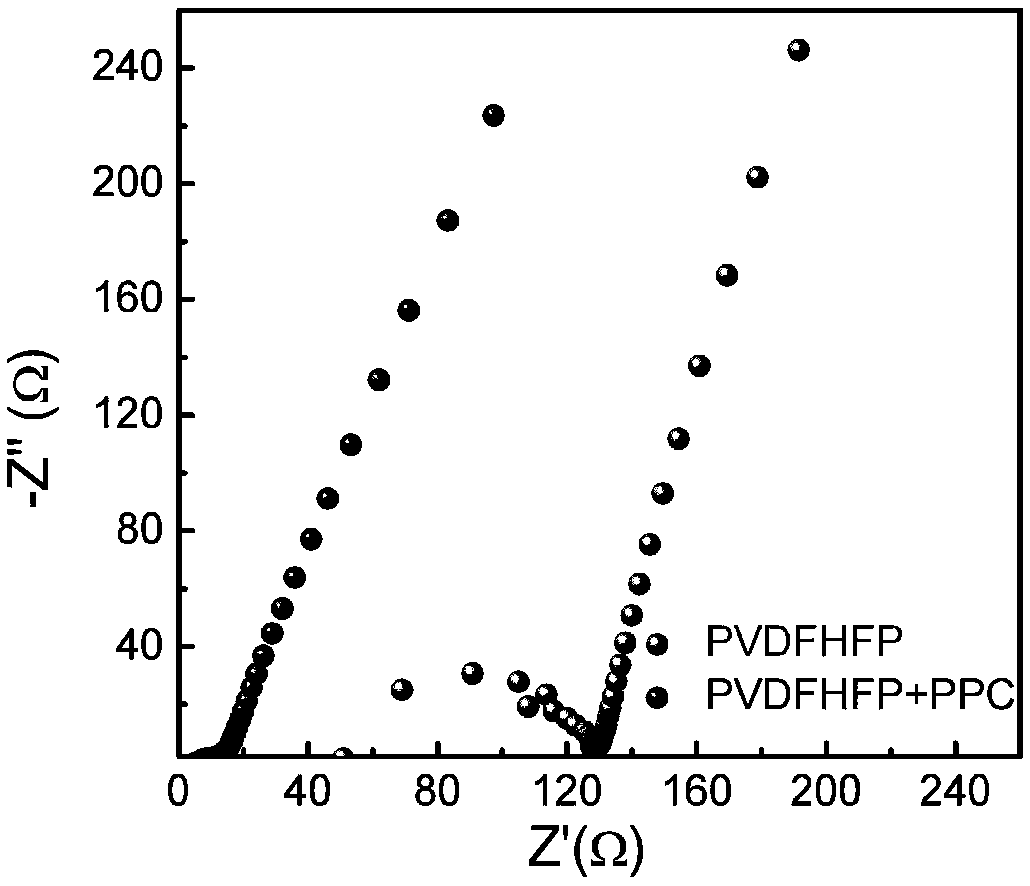

[0047] Using a scanning electron microscope to observe the modified ...

Embodiment 2

[0050] Dissolve 6 g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) in 40 g of N,N-dimethylformamide (DMF), sonicate for 10 minutes, and magnetically stir for 12 hours at room temperature to obtain a solution of polyvinylidene fluoride-hexafluoropropylene ; Polypropylene carbonate (PPC) 4g was dissolved in polyvinylidene fluoride-hexafluoropropylene solution, sonicated for 10 minutes, and magnetically stirred at room temperature for 12 hours to obtain a polymer solution;

[0051] Transfer the polymer solution into a clean Teflon mold (200mm×200mm), cast it naturally, and place it at room temperature for 30 minutes to stabilize the composite polymer system to obtain a modified polymer electrolyte wet film;

[0052] The obtained modified polymer electrolyte wet membrane was dried in a vacuum oven at 80° C. for 24 hours to obtain a modified polymer electrolyte membrane with a thickness of about 20 μm.

[0053] The modified polymer electrolyte membrane was observed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com