3D printing system based on virtual instrument

A technology of 3D printing and virtual instrument, applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve the problems of slow speed and weak editability, and achieve easy debugging, intuitiveness and easy operation , High printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] 1. Printer system construction

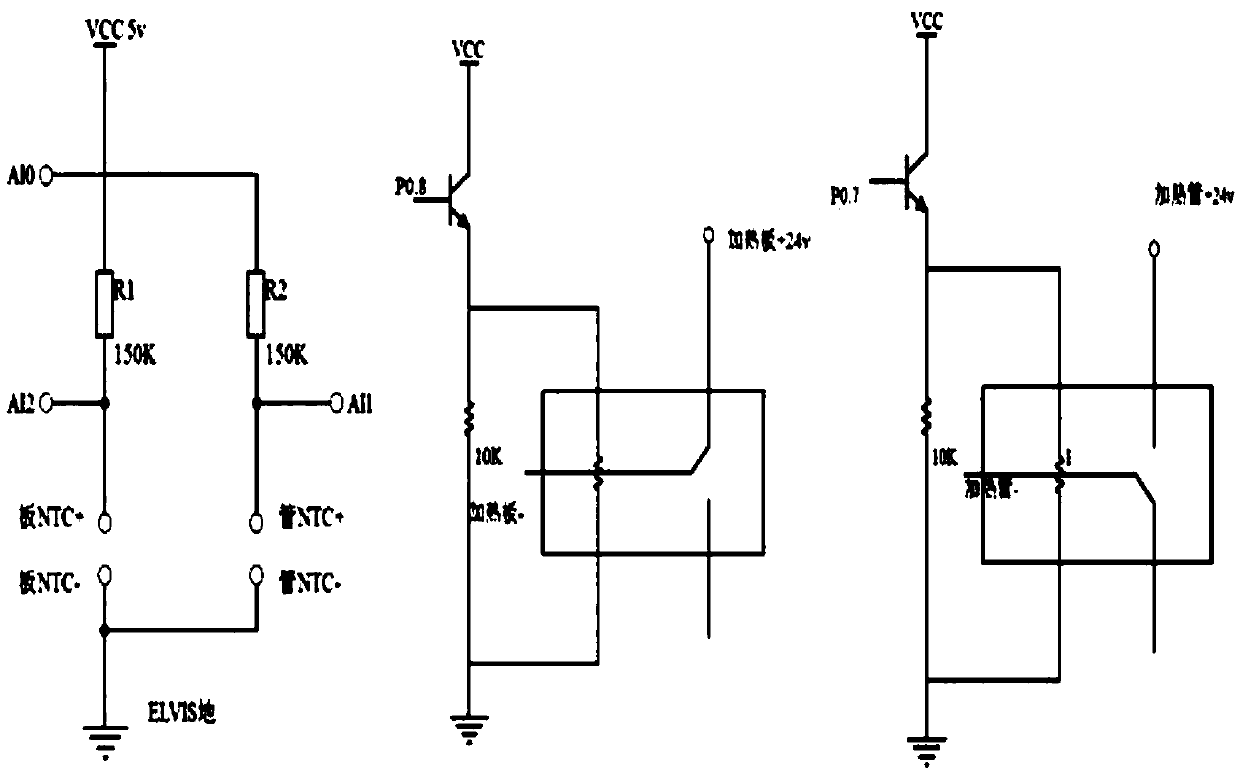

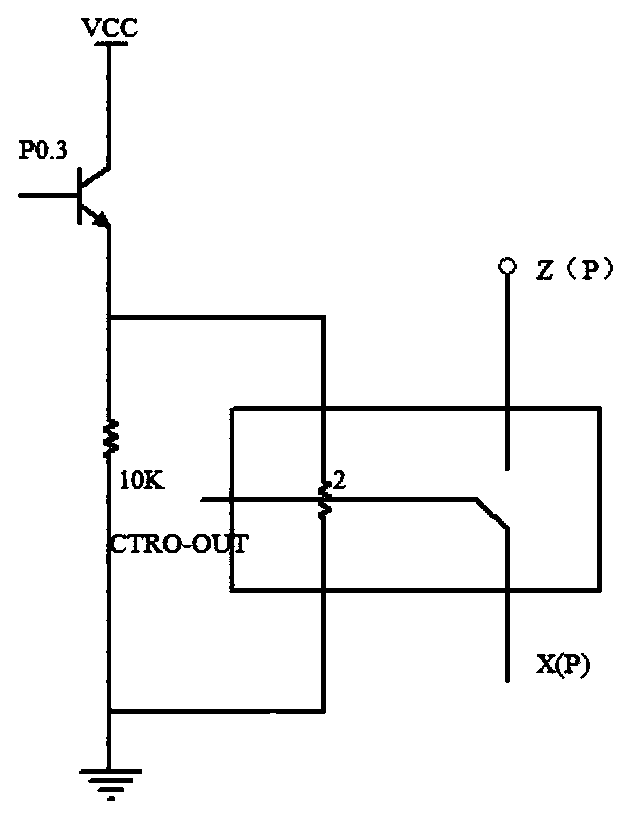

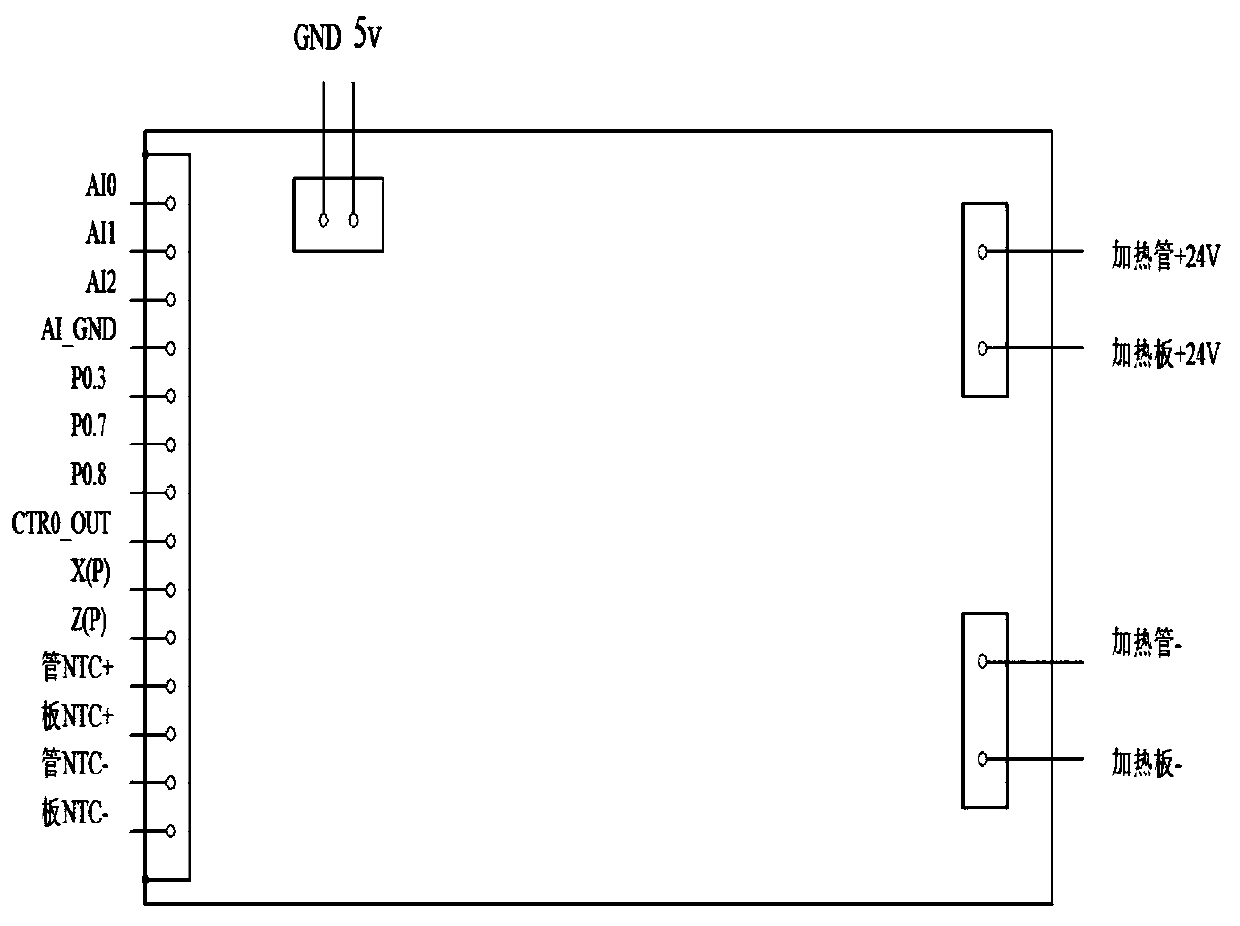

[0120] The 3D printer system designed by the present invention consists of three main parts: a mechanical printing body with a rectangular box structure, a data acquisition board and an upper computer (software). The mechanical body of the cassette mechanism includes aluminum alloy profiles, stepping motors, extruders, heating panels, functional circuits and some accessories. The data acquisition card uses NI Elvis II, and the host computer software is LabVIEW.

[0121] Mechanical main body-rectangular box structure. The characteristic of this structure is that the hot bed only moves in the Z-axis direction, and the nozzle only moves in the X / Y-axis direction. This structure can reduce the weight of the print head, thereby improving the printing speed and printing accuracy to a certain extent; the printing direction, printing length and printing materials are controlled by stepping motors;

[0122] Control circuit. In this system, components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com