Method for reducing dielectric loss of titanium barium stannate system in reducing atmosphere

A technology of barium titanium stannate and dielectric loss, which is applied in the field of ceramic compositions, can solve the problems of low resistivity, increased production cost, and high sintering temperature, and achieve the effect of reducing dielectric loss and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) The raw material BaTiO 3 , SnO 2 、BaCO 3 Press Ba(Sn 0.05 Ti 0.95 )O 3 Chemical formula weighing ingredients;

[0022] (2) Put the powder prepared above into a ball mill jar, add zirconia balls and deionized water, and ball mill for 4 hours. The mass ratio of powder to zirconia balls and deionized water is 1:1:2; The ball-milled raw materials are dried in an infrared drying oven at 100°C, and passed through a 40-mesh sieve after drying to obtain a powder with uniform particles;

[0023] (3) calcining the powder treated in step (2) at 1050° C. for 3 hours to synthesize the main crystal phase;

[0024] (4) Put the powder of the main crystal phase synthesized in step (3) into a ball mill tank, perform secondary ball milling, add zirconia balls and deionized water, and ball mill for 4 hours. The quality of the powder, zirconia balls, and deionized water The ratio is 1:1:2; the ball-milled raw materials are then dried in an infrared drying oven, and passed through...

Embodiment 2~8

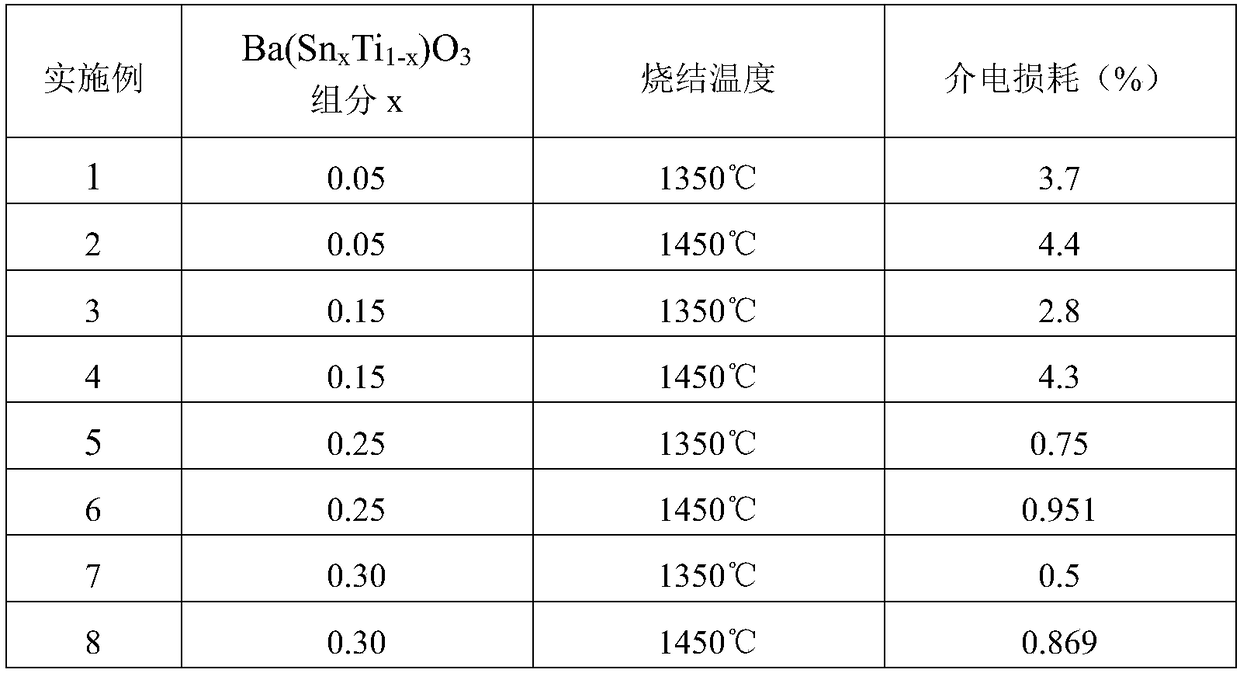

[0029] The main process parameters and dielectric loss of Examples 2-8 are detailed in Table 1, and the rest of the preparation process is exactly the same as that of Example 1.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com