A kind of silicon nitride ceramic and preparation method thereof

A technology of silicon nitride ceramics and silicon dioxide, which is applied in the field of silicon nitride ceramics and its preparation, can solve problems such as poor performance, complicated process, and long preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

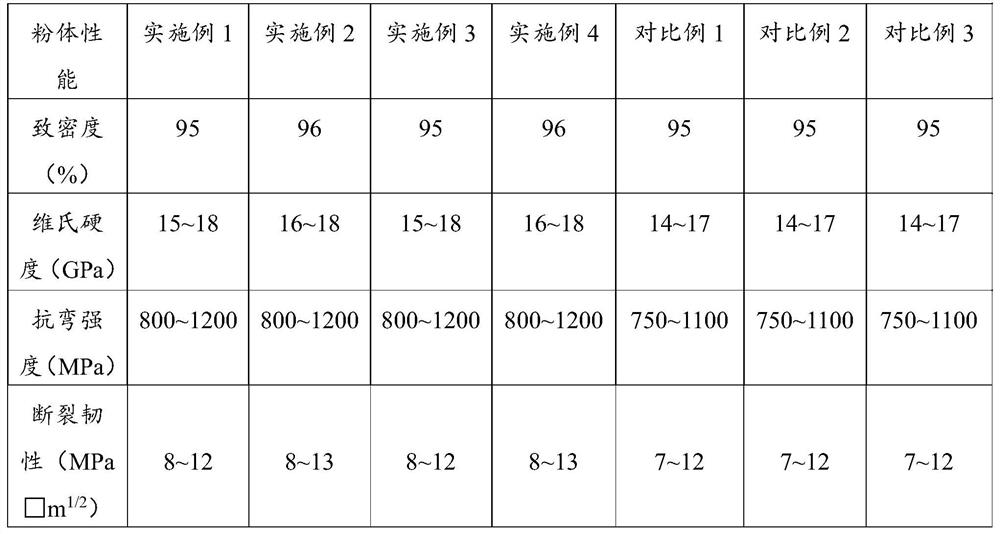

Examples

Embodiment 1

[0033] (1) Silica powder, melamine powder, aluminum oxide powder (Al 2 o 3 ) and Re 2 o 3 Powder as raw material, press C 3 h 6 N 6 : SiO 2 Mix the above two powders with a mole fraction ratio of 1:3. Among them, SiO 2 The purity of the powder is 98%~100%, the particle size is 5μm, C 3 h 6 N 6 The purity of the powder is 98%-100%, and the particle size is 5 μm. al 2 o 3 and Re 2 o 3 The purity of the powder is 98% to 100%, and the particle size is 0.1 μm

[0034] (2) With ethanol as solvent, with Si 3 N 4 The ball is a ball milling medium, mixed on a roller ball mill for 24 hours, the rotation speed is 100r / min, and after drying, the silica-melamine-Al 2 o 3 -Re 2 o 3 Mix powder.

[0035] (3) The above-mentioned mixed powder is formed by cold isostatic pressing to obtain a compact green body.

[0036] (4) Put the green body into a boron nitride crucible, first raise the temperature to 550°C at 10°C / min, and keep it for 1h; Dense silicon nitride ceramics...

Embodiment 2

[0038] 1) With silica powder, melamine powder, Al 2 o 3 and Re 2 o 3 Powder as raw material, press C 3 h 6 N 6 : SiO 2 Mix the above two powders with a mole fraction ratio of 1:3. Among them, SiO 2 The purity of the powder is 98%~100%, the particle size is 5μm, C 3 h 6 N 6 The purity of the powder is 98%-100%, and the particle size is 5 μm. al 2 o 3 and Re 2 o 3 The purity of the powder is 98% to 100%, and the particle size is 0.1 μm

[0039] (2) With ethanol as solvent, with Si 3 N 4The ball is a ball milling medium, mixed on a roller ball mill for 24 hours, the rotation speed is 100r / min, and after drying, the silica-melamine-alumina-Re 2 o 3 Mix powder.

[0040] (3) The above-mentioned mixed powder is formed by cold isostatic pressing to obtain a compact green body.

[0041] (4) Put the green body into a boron nitride crucible, first raise the temperature to 550°C at 10°C / min, and keep it for 1h; Dense silicon nitride ceramics are obtained after step v...

Embodiment 3

[0043] (1) Using silica powder, melamine powder, Al 2 o 3 Powder and Re 2 o 3 Powder as raw material, press C 3 h 6 N 6 : SiO 2 Mix the above two powders with a mole fraction ratio of 1:3. Among them, SiO 2 The purity of the powder is 98%~100%, the particle size is 5μm, C 3 h 6 N 6 The purity of the powder is 98%-100%, and the particle size is 5 μm. al 2 o 3 and Re 2 o 3 The purity of the powder is 98% to 100%, and the particle size is 0.1 μm

[0044] (2) With acetone as solvent, Si 3 N 4 The ball is a ball milling medium, mixed on a roller ball mill for 24 hours, the rotation speed is 100r / min, and after drying, the silica-melamine-alumina-Re 2 o 3 Mix powder.

[0045] (3) The above-mentioned mixed powder is formed by cold isostatic pressing to obtain a compact green body.

[0046] (4) Put the green body into a boron nitride crucible, first raise the temperature to 550°C at 10°C / min, and keep it for 1h; Dense silicon nitride ceramics are obtained after s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com