A kind of clathrate type slow-release urea fertilizer and its preparation method

A slow-release urea and clathrate technology, applied in urea compound fertilizers, fertilizer mixtures, solid/semi-solid fertilizers, etc., can solve problems such as difficult degradation, secondary pollution of the ecological environment, etc., achieve simplified production processes, promote degradation, Realize the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

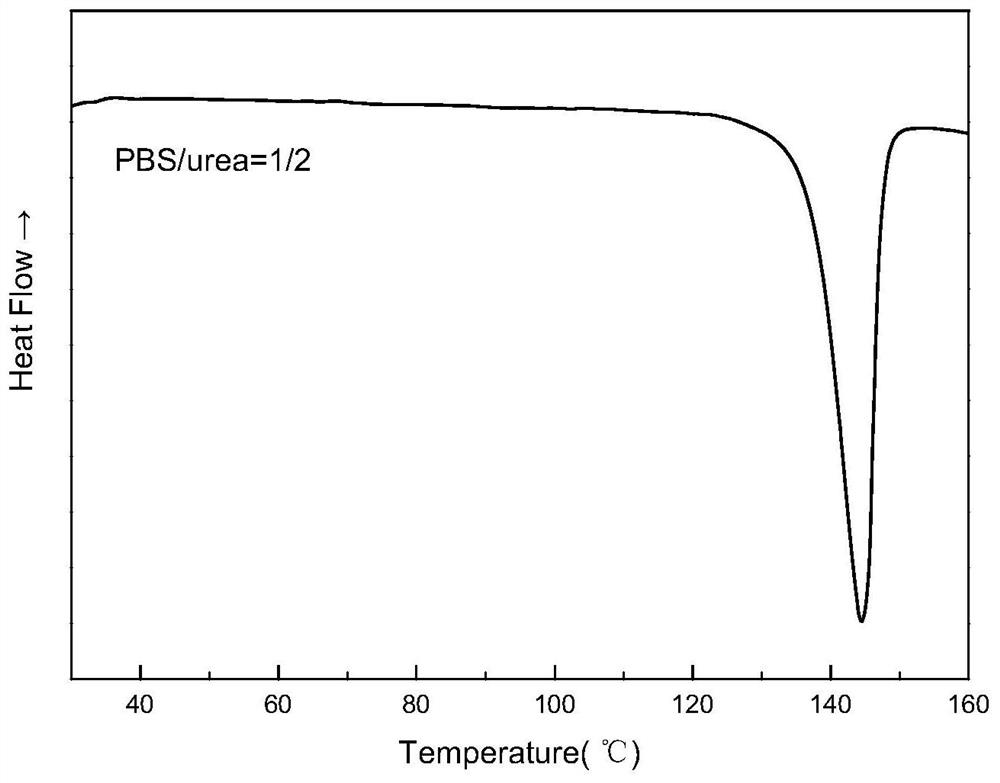

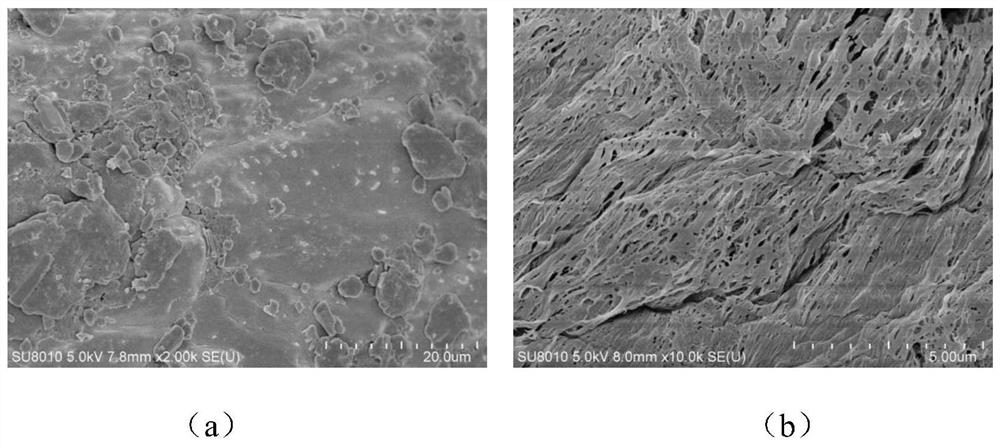

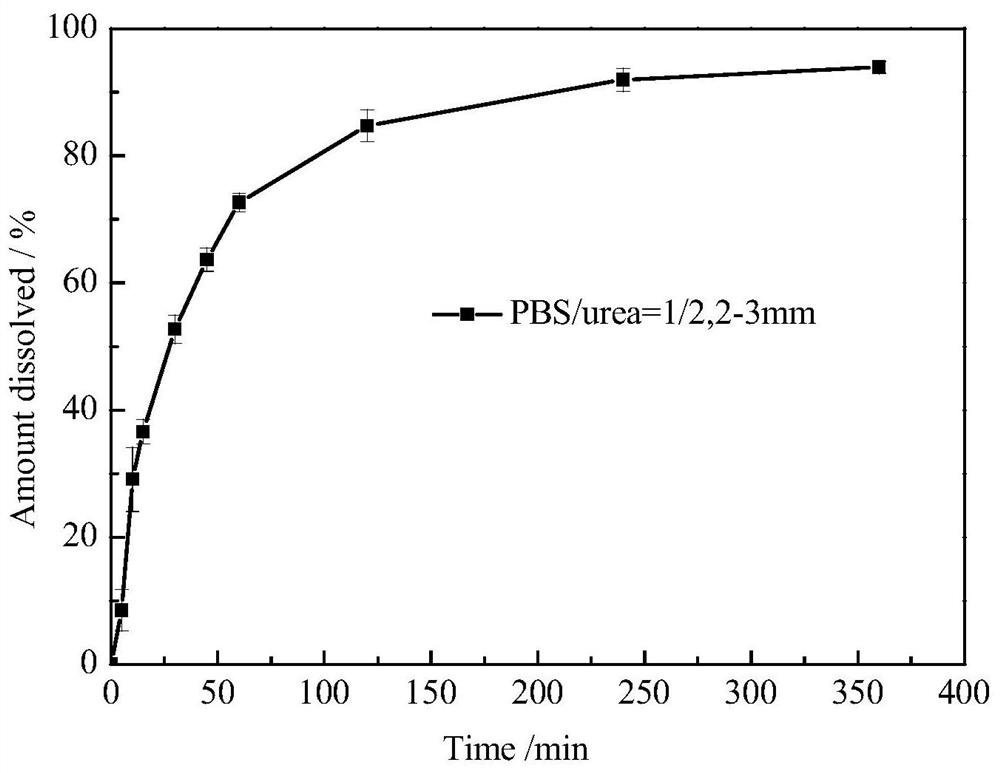

[0032] (1) A certain amount of polybutylene succinate (number-average molecular weight is 100000g / mol) is uniformly mixed with urea at room temperature in a container, and the mass ratio of polybutylene succinate to urea is 1: 2.

[0033] (2) The mixture obtained in step (1) was added into a Brabender internal mixer for blending, the temperature of the blending was 125° C., and the time was 15 minutes.

[0034] (3) Grinding the polymer-urea complex obtained in step (2) to obtain solid particles with different particle diameters (1-2mm, 2-3mm, 3-4mm, 4-5mm) is the urea sustained-release product. A clathrate-type slow-release urea fertilizer. The solid granular slow-release urea fertilizers with different particle sizes are sieved to obtain fractions with different particle sizes, so that slow-release urea fertilizers with different slow-release effects can be prepared.

Embodiment 2

[0036] (1) A certain amount of polyethylene succinate (number-average molecular weight is 200000g / mol) is uniformly mixed with urea at room temperature in a container, and the mass ratio of polyethylene succinate and urea is 1: 3.

[0037] (2) Add the mixture obtained in step (1) into an open mill for blending, the temperature of the blending is 120° C., and the time is 15 minutes.

[0038](3) Pulverize the polymer-urea complex obtained in step (2) to obtain solid particles (1-2mm, 2-3mm, 3-4mm, 4-5mm) of different particle sizes, which are urea sustained-release properties. A clathrate-type slow-release urea fertilizer. The solid granular slow-release urea fertilizers with different particle sizes are sieved to obtain fractions with different particle sizes, so that slow-release urea fertilizers with different slow-release effects can be prepared.

Embodiment 3

[0040] (1) A certain amount of polytrimethylene succinate (the number average molecular weight is 500000g / mol) and urea are uniformly mixed in a container at room temperature, and the mass ratio of polytrimethylene succinate to urea is 1:4.

[0041] (2) Add the mixture obtained in step (1) into a twin-screw extruder for blending. The blending temperature is 120° C. and the time is 20 min.

[0042] (3) Extrude and granulate the polymer-urea compound obtained in step (2) to obtain solid particles with different particle lengths (1-2mm, 2-3mm, 3-4mm, 4-5mm), that is, urea buffer A clathrate-type slow-release urea fertilizer with release properties. Slow-release urea fertilizers with different slow-release effects can be prepared by controlling the length of the slow-release urea fertilizer particles or matching different extrusion calibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com